High-Throughput Thin-Film Synthesis: Accelerating Discovery for Materials Science and Drug Development

This article provides a comprehensive overview of high-throughput thin-film synthesis techniques, a transformative approach for the rapid discovery and optimization of new materials.

High-Throughput Thin-Film Synthesis: Accelerating Discovery for Materials Science and Drug Development

Abstract

This article provides a comprehensive overview of high-throughput thin-film synthesis techniques, a transformative approach for the rapid discovery and optimization of new materials. Tailored for researchers, scientists, and drug development professionals, it explores the foundational principles of combinatorial methods, detailing key fabrication platforms such as magnetron sputtering, multi-arc ion plating, and solution-based processes. The scope extends to diverse applications in energy materials and drug discovery, addresses common troubleshooting and optimization challenges with insights from AI-driven platforms, and validates findings through integrated high-throughput characterization. By synthesizing these core intents, the article serves as a guide for leveraging these accelerated methodologies to shorten R&D cycles and meet pressing technological needs.

The Paradigm Shift: From Serendipity to Data-Driven Materials Discovery

Defining High-Throughput and Combinatorial Materials Science

High-Throughput and Combinatorial Materials Science (CMS) represents a paradigm shift in materials research, moving away from traditional sequential investigation of individual compositions toward the parallel synthesis, processing, and characterization of large material libraries. This approach enables the rapid exploration of complex composition spaces and the establishment of comprehensive structure-property relationships. At its core, CMS relies on integration of specialized methodologies—combinatorial synthesis creates materials libraries containing hundreds to thousands of discrete compositions in a single experiment, while high-throughput characterization employs automated, spatially-resolved techniques to efficiently map properties across these libraries [1]. The resulting multidimensional datasets provide the foundation for accelerated materials discovery, optimization, and deployment across various technological domains, from sustainable energy to pharmaceutical development [1] [2].

The fundamental advantage of this methodology lies in its systematic approach to navigating the immense search space of potential materials. With more than 40 earth-abundant, non-toxic elements that can be combined into multinary systems, the number of possible material combinations reaches into the millions even for relatively simple systems [1]. High-throughput computational screening helps down-select promising regions of this composition space, which are then experimentally realized as thin-film materials libraries through combinatorial synthesis techniques [1]. This integrated strategy has transformed materials research from a traditionally serendipity-driven endeavor to a systematic, data-guided process capable of efficiently addressing complex technological challenges.

Key Methodologies and Workflows

Combinatorial Synthesis of Materials Libraries

Combinatorial synthesis forms the foundational step in CMS, enabling the efficient fabrication of materials libraries that systematically explore composition spaces. The most prevalent approach involves thin-film deposition techniques, particularly combinatorial magnetron sputtering, which offers exceptional control over composition gradients and microstructure [1]. Two primary methods are employed for library fabrication:

- Wedge-type multilayer deposition utilizes computer-controlled movable shutters to deposit nanoscale layers oriented at specific angles (180° for binaries, 120° for ternaries). Subsequent annealing at optimized temperatures induces interdiffusion and phase formation, transforming the layered precursor into compositionally graded libraries [1].

- Co-deposition methods involve simultaneous sputtering from multiple sources, creating atomic mixtures in the deposited film. This technique is particularly suitable for fabricating "focused" compositional gradient libraries around predicted compositions and for stabilizing metastable materials when performed at room temperature [1].

These synthesis approaches enable the creation of both complete multinary materials systems and tailored composition gradients designed to verify or falsify computational predictions [1]. The resulting materials libraries serve as platforms for subsequent high-throughput characterization, providing comprehensive coverage of composition spaces while maintaining consistent processing conditions across all library members.

High-Throughput Characterization Techniques

High-throughput characterization employs automated, spatially-resolved analytical techniques to rapidly determine the compositional, structural, and functional properties of materials within combinatorial libraries. These methods must provide sufficient resolution to map variations across libraries while maintaining data quality comparable to conventional materials characterization. Essential characterization modalities include:

Structural and Chemical Analysis

- Scanning X-ray diffraction (XRD) maps phase formation and structural parameters across composition gradients [3]

- Energy dispersive X-ray analysis (EDX) quantitatively determines compositional variations with high spatial resolution [3]

- Spatially-resolved spectroscopic techniques including micro-Raman spectroscopy and ToF-SIMS 3D mapping [4]

Functional Property Mapping

- Scanning Magneto-Optical-Kerr-Effect (MOKE) systems probe magnetic properties such as coercivity across composition spreads [3]

- Automated electrical and optical characterization systems measure functional responses relevant to specific applications

- Advanced mechanical testing including nanoindentation and micro-scale testing under various environmental conditions [4]

The integration of these characterization techniques enables the correlation of functional properties with underlying composition and structure, facilitating the identification of composition-property relationships and the discovery of new materials with exceptional characteristics [3].

Data Management and Analysis Frameworks

The implementation of CMS generates complex, multidimensional datasets that require sophisticated management and analysis approaches. The FAIR data principles (Findable, Accessible, Interoperable, and Reusable) provide a critical framework for ensuring the long-term value and utility of these datasets [5]. Key considerations include:

- Metadata schemas that comprehensively describe data provenance, processing parameters, and experimental conditions [5]

- Materials informatics approaches that employ machine learning and data mining to extract meaningful patterns and relationships from high-dimensional data [1]

- Standardized file formats and data exchange protocols that facilitate collaboration and data sharing across research institutions [5]

Effective data management transforms raw characterization data into actionable knowledge, supporting both immediate materials optimization and future repurposing of data for applications not originally envisioned [5].

Experimental Protocols

Protocol: Combinatorial Synthesis of Compositionally Graded Fe-Pt Thin Films

Objective: To fabricate compositionally graded Fe-Pt thin film libraries for high-throughput investigation of magnetic properties [3].

Table 1: Key Research Reagent Solutions and Materials

| Item | Specification | Function |

|---|---|---|

| Si Substrate | 100 mm diameter, (100) oriented | Inert, flat support for film growth |

| Fe Target | High purity (99.95%) base target | Primary source of Fe for sputtering |

| Pt Piece | High purity (99.95%), various sizes | Composition control through asymmetric positioning |

| Sputtering System | Magnetron sputtering with controlled atmosphere | Thin film deposition technique |

| Annealing Furnace | Programmable temperature with inert gas capability | Post-deposition phase formation |

Step-by-Step Procedure:

Substrate Preparation: Clean 100 mm Si substrates using standard RCA cleaning procedure. Mount substrate in stationary position within sputtering chamber.

Combinatorial Sputtering Configuration:

- Position Fe target in magnetron sputtering source

- Asymmetrically place Pt piece of predetermined size on Fe target surface

- This configuration creates natural composition gradients across the stationary substrate during deposition

Deposition Parameters:

- Base pressure: ≤ 5 × 10⁻⁶ Torr

- Sputtering gas: Argon at 3 mTorr working pressure

- Deposition power: DC power at 100 W for Fe target

- Deposition time: Optimized to achieve 50-100 nm film thickness

- Substrate temperature: Room temperature (25°C)

Post-Deposition Annealing:

- Transfer samples to tube furnace with controlled atmosphere

- Anneal under forming gas (Ar + 5% H₂) or vacuum (≤ 10⁻⁵ Torr)

- Systematically vary annealing temperature (300-600°C) and time (30-120 minutes) across library sections

- Rapidly quench samples to room temperature after annealing

Quality Control Measures:

- Verify thickness uniformity using profilometry across multiple substrate positions

- Confirm absence of oxidation through X-ray photoelectron spectroscopy (XPS) spot analysis

- Validate compositional gradient reproducibility through EDX mapping of multiple libraries

Protocol: High-Throughput Characterization of Magnetic Properties

Objective: To rapidly map coercivity across compositionally graded Fe-Pt libraries and correlate with structural properties [3].

Procedure:

Compositional Mapping:

- Utilize energy dispersive X-ray (EDX) analysis with automated stage

- Establish composition grid with measurement points every 2-5 mm across substrate

- Generate composition map correlating substrate position with Fe/Pt ratio

Structural Characterization:

- Perform scanning X-ray diffraction (XRD) using synchrotron or laboratory source

- Map phase formation across composition spread

- Identify L1₀ FePt phase formation and track lattice parameter evolution

Magnetic Property Screening:

- Employ scanning polar Magneto-Optical-Kerr-Effect (MOKE) system

- Measure hysteresis loops at positions corresponding to EDX and XRD measurement points

- Extract coercivity values and remanent magnetization for each composition

Data Correlation:

- Create comprehensive dataset linking composition, annealing conditions, crystal structure, and magnetic properties

- Identify composition and processing windows that maximize coercivity

- Validate structure-property relationships through coordinated analysis

Table 2: High-Throughput Characterization Techniques in Materials Science

| Characterization Method | Property Measured | Throughput | Spatial Resolution |

|---|---|---|---|

| Energy Dispersive X-ray (EDX) | Chemical composition | ~100 points/hour | 1-10 μm |

| Scanning X-ray Diffraction | Crystal structure, phase identification | ~50 points/hour | 10-100 μm |

| Magneto-Optical-Kerr-Effect | Magnetic coercivity, hysteresis | ~200 points/hour | 1-5 mm |

| Automated Nanoindentation | Mechanical properties, hardness | ~50 points/hour | 1-10 μm |

| Spatially-Resolved Spectroscopy | Electronic structure, bonding | ~20 points/hour | 0.5-2 μm |

Applications Across Research Domains

Energy Materials Discovery

The CMS approach has demonstrated particular utility in sustainable energy materials research, where complex multinary compounds often exhibit the required combination of functional properties. Notable applications include:

- Photoelectrode materials for solar water splitting, where high-throughput screening identified 43 new potential photocathodes for CO₂ reduction from 68,860 candidate materials [1]

- Noble-metal-free catalysts for fuel cells and electrolyzers, exemplified by the discovery of CrMnFeCoNi high-entropy alloy nanoparticles with significant oxygen reduction activity [1]

- Photovoltaic materials exploration, including the identification of defect-tolerant semiconducting nitrides through reactive co-sputtering combinatorial approaches [1]

These applications benefit from the ability of CMS to efficiently navigate complex composition spaces where multiple elements must be optimized simultaneously to achieve desired electronic, catalytic, and stability properties.

Pharmaceutical and Biomaterials Development

High-throughput screening methodologies have been extensively adapted from materials science to pharmaceutical research, creating powerful tools for drug discovery and toxicology assessment:

- Compound screening against biological targets at rates exceeding 100,000 compounds per day using ultra-high-throughput screening (UHTS) platforms [2]

- Toxicity assessment using cellular microarrays in 384-well or 1586-well microtiter plates, enabling early identification of safety issues before significant investment in clinical trials [2]

- ADME-Tox profiling (Absorption, Distribution, Metabolism, Excretion, and Toxicology) using in silico methods and predictive quantitative structure-activity relationship (QSAR) modeling [2]

The miniaturization and automation of biological assays have significantly reduced development costs while increasing the quality of candidate compounds advancing through the development pipeline [2].

Implementation Guidelines

Data Management and FAIR Principles

Effective implementation of CMS requires meticulous attention to data management throughout the research lifecycle. The FAIR principles provide a robust framework for ensuring data quality and long-term utility:

Findability

- Assign persistent identifiers (PIDs) to all datasets and materials libraries

- Register metadata in searchable resources with rich annotation

- Implement comprehensive sample tracking systems [5]

Accessibility

- Develop application programming interfaces (APIs) for data query and retrieval

- Ensure authentication and authorization protocols balance security with access

- Maintain data archives with clear retention and access policies [5]

Interoperability

- Employ formal ontologies for knowledge representation in materials science

- Use standardized vocabularies for data and metadata annotation

- Include references to related datasets and publications [5]

Reusability

- Document comprehensive provenance information including all processing parameters

- Provide clear descriptions of data collection methodologies and instrumentation

- Include uncertainty estimates and quality metrics for all measured properties [5]

Technology Transfer and Industrial Implementation

The transition from research discovery to industrial application represents a critical phase in the materials development pipeline. Successful implementation strategies include:

- Combinatorial processing optimization to bridge the gap between discovery synthesis and manufacturable processes [1]

- Integration of high-throughput methods at multiple technology readiness levels (TRL), from basic research to product development [4]

- Development of standardized protocols for data exchange between academic, national laboratory, and industrial partners [5]

Industrial adoption of CMS approaches has been particularly significant in sectors where materials performance directly impacts product competitiveness, including energy storage, catalytic processing, and electronic materials development [4].

High-Throughput and Combinatorial Materials Science represents a transformative approach to materials research that systematically addresses the immense complexity of multinary composition spaces. Through the integrated application of combinatorial synthesis, high-throughput characterization, and advanced data science, CMS enables efficient navigation of the multidimensional search space defining materials structure, processing, and properties. The continued development of automated experimental systems, sophisticated characterization tools, and FAIR-compliant data management practices will further accelerate materials discovery and optimization across diverse technological domains. As these methodologies mature and become more widely adopted, they promise to significantly shorten development timelines and enhance our fundamental understanding of materials behavior, ultimately supporting the creation of advanced materials needed to address pressing global challenges in energy, healthcare, and sustainability.

The development of advanced materials, particularly for applications in energy harvesting and electronics, increasingly relies on the exploration of multinary systems—materials containing three or more constituent elements. The compositional landscape of these materials is vast, creating an immense search space that traditional trial-and-error methodologies cannot efficiently navigate [6]. For example, in the case of halide perovskites for photovoltaic applications, the search for optimal compositions that balance high efficiency with environmental stability presents a particularly challenging optimization problem [6]. Similarly, the emergence of entropy-stabilized oxides (ESOs) composed of five or more cationic elements has opened new possibilities for designing materials with unique functional properties, but at the cost of exponentially increasing compositional complexity [7].

High-throughput thin film synthesis techniques have emerged as powerful tools to address this challenge, enabling the rapid fabrication and screening of numerous compositional variants. When combined with machine learning (ML) algorithms and data fusion approaches, these techniques can dramatically accelerate the discovery and optimization of novel materials [4] [6]. This Application Note details the protocols and methodologies for effectively navigating multinary compositional landscapes, with specific examples drawn from perovskite and entropy-stabilized oxide research, framed within the broader context of a thesis on high-throughput thin film synthesis.

High-Throughput Workflow Design

Core Concept of the Data Fusion Approach

The fundamental challenge in multinary material development is the sheer number of possible compositions. A comprehensive exploration of all combinations through traditional methods is often prohibitively time-consuming and resource-intensive. The solution lies in a closed-loop optimization framework that integrates high-throughput experimentation with computational guidance [6].

This approach seamlessly marries data from first-principles calculations and high-throughput experimentation into a single machine learning algorithm, creating an iterative cycle of prediction, synthesis, testing, and learning [6] [8]. The machine learning model, typically based on Bayesian optimization, uses all available data to predict which compositions are most likely to exhibit the desired properties, thereby intelligently guiding the next round of experiments. This process effectively takes the human out of the decision-making loop, enabling a more efficient exploration of the compositional space.

Table 1: Key Components of a High-Throughput Data Fusion Workflow

| Component | Function | Implementation Example |

|---|---|---|

| Combinatorial Synthesis | Simultaneously produces multiple compositional variants on a single substrate. | Pulsed laser deposition from mixed-oxide targets [7]. |

| High-Throughput Characterization | Rapidly assesses properties (optical, structural, electronic) across the compositional spread. | In situ degradation tests, photoluminescence imaging [6]. |

| Data Management Platform | Handles the large, multi-modal datasets generated. | Custom software for data fusion from experimental and computational sources [6]. |

| Machine Learning Core | Analyzes data, identifies patterns, and recommends next experiments. | Bayesian optimization with probabilistic constraints [6] [8]. |

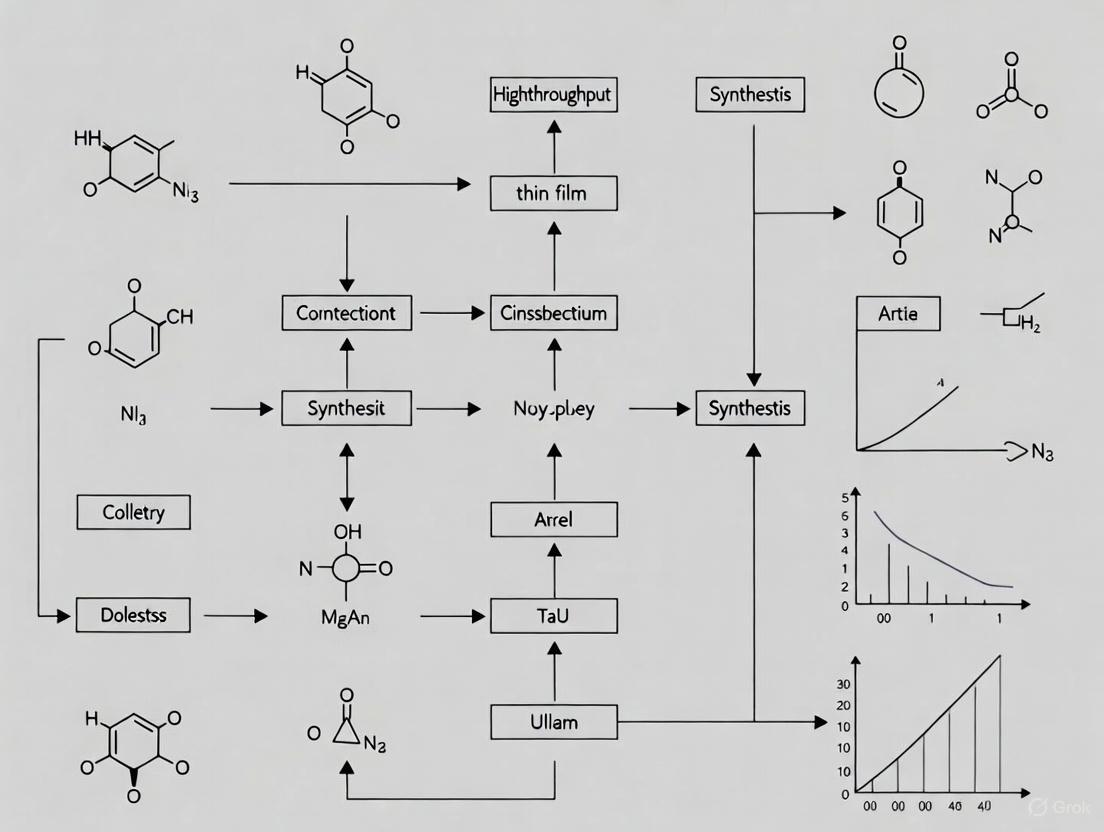

Experimental Workflow Visualization

The following diagram illustrates the integrated, iterative workflow for navigating multinary compositional spaces using high-throughput techniques and machine learning.

Diagram 1: Closed-loop workflow for compositional optimization. The process integrates physics-based computational data and machine learning to guide high-throughput experiments efficiently.

Protocols for High-Throughput Synthesis and Characterization

Protocol: Combinatorial Synthesis of Entropy-Stabilized Oxide (ESO) Thin Films

This protocol details the synthesis of phase-pure, single-crystalline ESO thin films via pulsed laser deposition (PLD), adapted from the method of et al. [7].

3.1.1. Bulk Ceramic Target (Source Material) Preparation

- Mass Calculation: Calculate the required mass of each constituent oxide powder (e.g., MgO, CoO, NiO, CuO, ZnO) for the target stoichiometry. The total mass is estimated by multiplying the desired pellet volume by the theoretical density, which is calculated as the mole-fraction-weighted average of the constituent oxide densities [7].

- Powder Processing:

- Clean an agate pestle and mortar by etching with aqua regia (HNO₃ + 3 HCl), followed by thorough rinsing with water.

- Combine the calculated masses of oxide powders in the mortar.

- Grind the powder mixture using clockwise and counter-clockwise motions for a minimum of 45 minutes until the mixture is homogeneous, finely ground, and smooth to the touch [7].

- Pellet Pressing:

- Assemble a uniaxial press die. Lubricate the bottom plunger and insert it into the die cylinder.

- Transfer the ground powder into the die cavity. Tap gently to remove air pockets.

- Add a small amount of acetone to form a slurry that inhibits void formation during pressing.

- Insert the top plunger and place the assembled die into a cold uniaxial press.

- Apply a pressure of 200 MPa and maintain for 20 minutes, replenishing pressure as needed due to powder densification.

- Carefully release the pressure and eject the "green body" target from the die [7].

- Sintering and Quenching:

- Place the green body on a bed of Yttria-Stabilized Zirconia (YSZ) beads in an alumina crucible to prevent contact with the crucible bottom.

- Sinter the target at 1100 °C for 24 hours in an air atmosphere.

- After sintering, immediately remove the crucible from the furnace and quench the target in room-temperature water to retain the high-temperature, entropy-stabilized phase [7].

- Measure the density of the sintered pellet. If density is below ~90% of theoretical, regrind and repeat the pressing and sintering steps.

3.1.2. Pulsed Laser Deposition of Thin Films

- Substrate Preparation: Use (001)-oriented MgO single crystal substrates. Standard cleaning procedures (e.g., solvent rinsing) should be followed.

- Deposition Parameters:

- Place the sintered ESO target in the PLD chamber.

- Heat the substrate to a temperature typically between 600-800 °C under a controlled oxygen partial pressure.

- Use a KrF excimer laser (λ = 248 nm) focused on the rotating target. Typical laser fluence is 1.5 - 2.5 J/cm² with a repetition rate of 1-10 Hz.

- Deposit for a duration required to achieve the desired film thickness (e.g., 20-50 nm).

- Post-Deposition: After deposition, anneal the film in situ at the growth temperature for a short period (e.g., 10-30 minutes) to improve crystallinity and chemical homogeneity. Cool the film slowly (e.g., at 5-10 °C/min) in the deposition atmosphere [7].

Protocol: In Situ Degradation Testing for Perovskite Compositional Stability

This protocol outlines a high-throughput method for assessing the stability of perovskite compositions, such as CsₓMAᵧFA₁₋ₓ₋ᵧPbI₃, under environmental stressors [6].

- Combinatorial Library Fabrication: Prepare a composition-spread thin film library using techniques such as combinatorial co-evaporation or automated solution-based printing onto a single substrate.

- Stability Chamber Setup: Place the combinatorial library in a controlled environmental chamber that allows simultaneous application of:

- Temperature: Elevated temperature (e.g., 85 °C).

- Humidity: High relative humidity (e.g., 85% RH).

- Illumination: Simulated solar spectrum light (e.g., 1 Sun intensity).

- Optical Monitoring: Use an automated, time-lapse optical imaging system (e.g., a CCD camera with controlled lighting) to capture images of the entire library at regular intervals (e.g., every minute or hour).

- Data Quantification: For each distinct composition on the library, quantify the optical change over time. A common metric is the normalized change in reflected or transmitted light intensity, which serves as a proxy for material degradation (e.g., decomposition or phase segregation) [6].

- Stability Metric Definition: Define a stability metric, such as the time for the optical signal to change by a certain threshold (e.g., 10%), or the total cumulative change after a fixed duration of stress exposure.

Data Analysis and Machine Learning Integration

Key Performance Metrics for High-Throughput Screening

The effectiveness of a high-throughput workflow depends on robust, quantitative metrics. The following table summarizes key metrics used in screening multinary compositions, drawing from both materials science and molecular biology best practices (e.g., MIQE guidelines for qPCR) [9].

Table 2: Key Quantitative Metrics for High-Throughput Screening

| Metric | Definition | Application in Multinary Materials |

|---|---|---|

| Stability Index | A quantitative measure of resistance to degradation under stress (e.g., time to 10% optical change). | Primary screening parameter for perovskite stability under heat, light, and moisture [6]. |

| Figure of Merit (FoM) | A composite score combining multiple properties (e.g., efficiency, stability, cost). | Used for multi-objective optimization, ranking compositions based on overall performance. |

| PCR Efficiency | Measure of amplification efficiency in qPCR (90-110% ideal). | Serves as an analogue for assay robustness in high-throughput biological contexts [9]. |

| ΔCq (Delta Cq) | Difference in quantification cycle between no-template control and low-abundance sample. | Analogous to signal-to-background ratio; useful for quantifying detection limits in screening [9]. |

| Linearity (R²) | Coefficient of determination for a standard curve. | Indicates the reliability and dynamic range of a quantitative high-throughput measurement [9]. |

Bayesian Optimization with Probabilistic Constraints

The core of the data fusion approach is a Bayesian optimization (BO) loop. BO is a sequential design strategy that uses a probabilistic model (e.g., Gaussian Process) to find the maximum of an expensive-to-evaluate function—in this case, material performance [6] [8].

- Model Initialization: The model is initialized with data from a small set of initial experiments and/or from first-principles calculations of phase thermodynamics.

- Acquisition Function: An acquisition function (e.g., Expected Improvement), which balances exploration of uncertain regions and exploitation of known promising areas, guides the selection of the next batch of compositions to test.

- Probabilistic Constraints: To incorporate physical knowledge, thermodynamic stability predictions from density functional theory (DFT) can be integrated as probabilistic constraints. This penalizes compositions predicted to form unstable or deleterious minority phases, making the search more efficient [6] [8].

- Iteration: The loop of prediction, synthesis, testing, and model updating continues until a convergence criterion is met (e.g., performance plateaus or a target is reached).

Case Study: Optimizing Halide Perovskite Stability

A landmark study demonstrated the power of this approach by optimizing the compositional stability of CsₓMAᵧFA₁₋ₓ₋ᵧPbI₃ perovskites [6] [8].

- Challenge: Navigate a complex ternary cation space (Cs, MA, FA) to find the most stable composition against moisture, heat, and light.

- Implementation: A closed-loop framework fused data from high-throughput in situ degradation tests and first-principle calculations into a Bayesian optimization algorithm.

- Result: After sampling only 1.8% of the discretized compositional space, the algorithm identified compositions centered at Cs₀.₁₇MA₀.₀₃FA₀.₈₀PbI₃. This composition exhibited a >17-fold stability improvement over standard MAPbI₃ and a 3-fold improvement over a more complex state-of-the-art multi-halide composition [6].

- Validation: Synchrotron-based GIWAXS confirmed the suppression of chemical decomposition and the detrimental δ-CsPbI₃ minority phase, validating the model's predictions and providing fundamental insight [6] [8].

The Scientist's Toolkit: Essential Research Reagent Solutions

Table 3: Key Materials and Reagents for High-Throughput Thin Film Research

| Item | Function / Application | Specific Example |

|---|---|---|

| High-Purity Oxide Powders | Starting materials for synthesizing ceramic targets for PVD. | MgO, CoO, NiO, CuO, ZnO for ESO synthesis [7]. |

| Metal-Organic Precursors | For solution-based deposition of combinatorial libraries. | Lead(II) iodide, methylammonium iodide, formamidinium iodide for perovskites [6]. |

| Single-Crystal Substrates | Epitaxial growth of high-quality thin films. | (001)-oriented MgO substrates for ESO films [7]. |

| Sintering Aids | Prevent adhesion and promote high-density sintering of ceramic targets. | Yttria-Stabilized Zirconia (YSZ) beads [7]. |

| Fluorescent Probes / Dyes | For functional assays and high-throughput detection. | SYBR Green I for qPCR analysis in assay development [9]. |

| Bayesian Optimization Software | Core algorithm for guiding experimental design and data fusion. | Custom Python scripts utilizing libraries like Scikit-learn or GPyOpt [6]. |

The challenge of navigating the immense search space of multinary compositional landscapes is being met by integrated workflows that combine high-throughput synthesis, automated characterization, and machine learning. The outlined protocols and the case study on perovskites demonstrate that fusing experimental data with physical models within a Bayesian optimization framework can dramatically accelerate the discovery of optimal materials. This data fusion approach, which takes the human out of the decision-making loop, is generalizable to a wide range of multinary systems beyond perovskites and oxides, promising to significantly shorten the development cycle for next-generation functional materials.

In the field of accelerated materials science, the exploration of multinary material systems is a formidable challenge due to the virtually unlimited combinatorial space of possible elemental combinations [1]. High-throughput experimental frameworks have been developed to efficiently navigate this vast search space, transitioning materials discovery from serendipitous findings to a systematic, data-guided process [1]. Central to this approach are three interconnected concepts: materials libraries (MLs), composition spreads, and existence diagrams. These components form the backbone of a methodology that enables the rapid fabrication, characterization, and understanding of material systems in a fraction of the time required by traditional sequential approaches.

Materials libraries are well-defined sets of materials—suitable for high-throughput characterization—produced in a single experiment under identical conditions [1]. When these libraries incorporate continuous composition gradients, they are often termed composition spreads. The data extracted from these libraries feed into existence diagrams, which are multidimensional maps that correlate composition, processing, structure, and properties [1]. Together, this framework supports efficient materials discovery and provides the datasets necessary for the inverse design of new materials with targeted properties.

Theoretical Foundations and Definitions

Materials Libraries (MLs)

A Materials Library is a systematically designed collection of samples created to explore a defined parameter space efficiently. In thin-film research, MLs can be fabricated as discrete sample arrays or as continuous composition spreads [10]. The power of MLs lies in their ability to contain numerous material variations within a single fabricated entity, enabling parallel rather than sequential investigation [1].

Composition Spreads

Composition spreads are a specific type of materials library featuring continuous gradients in chemical composition across a substrate [1]. These gradients can cover complete ternary systems or large fractions of higher-order systems, allowing researchers to investigate all possible compositions within a targeted system without discrete gaps [11]. This approach is often termed "continuous-composition optimization" and provides a comprehensive view of composition-property relationships [11].

Existence Diagrams

Existence diagrams are multidimensional maps that visualize correlations between composition, processing parameters, crystal structure, and functional properties [1]. These diagrams evolve from traditional phase diagrams by incorporating additional dimensions beyond just composition and temperature, including processing parameters and functional properties. They serve as predictive tools for materials design by establishing the existence regions of specific phases or properties under various synthesis conditions [1].

Synthesis Protocols for Materials Libraries

Continuous Composition Spreads via Combinatorial Sputtering

Principle: Utilizes the natural deposition rate variation from multiple non-coincident sputter sources to create thin films with controlled composition gradients [12].

Table 1: Key Parameters for Combinatorial Sputtering

| Parameter | Specification | Function |

|---|---|---|

| Sputter Sources | 3 non-coincident magnetron targets | Creates composition gradient across substrate |

| Deposition Method | Co-sputtering or wedge-type multilayer | Achieves atomic mixture or layered precursor |

| Substrate Positioning | Fixed or rotated (120° for ternaries) | Controls composition profile and uniformity |

| Post-Deposition Annealing | Temperature-controlled rapid thermal processing | Induces phase formation through interdiffusion |

Experimental Protocol:

- Substrate Preparation: Clean 100mm Si wafer with standard RCA protocol; mount in sputter chamber [3] [10].

- Target Configuration: Install three elemental targets (e.g., Cu, Cr, Co) with asymmetric positioning relative to substrate [13] [3].

- Deposition Parameters: Set base pressure to 1×10⁻⁶ Torr; maintain Ar gas flow at 20 sccm; DC power setting: 100W per target [13].

- Shutter Programming: For wedge-type deposition, program computer-controlled movable shutters to deposit nanoscale layers with thickness gradients [1].

- Multilayer Sequencing: For ternary systems, rotate substrate by 120° between deposition steps; control layer thickness to achieve desired composition range [1].

- Post-Deposition Annealing: Transfer library to rapid thermal processor; anneal at 400-700°C for 1-60 minutes in controlled atmosphere to promote interdiffusion and phase formation [13].

Discrete Library Synthesis via Mask-Assisted Deposition

Principle: Uses physical masks to create arrays of individually separated thin-film samples with distinct compositions [10].

Experimental Protocol:

- Mask Design: Fabricate shadow mask with 10×10 array of 1mm diameter openings using laser-cut stainless steel [10].

- Sequential Deposition: For each compositional variation, align mask to specific substrate regions and deposit through respective openings [10].

- Composition Control: Vary deposition time or power for each element to systematically change composition across array [10].

- Library Format: Result is 100 discrete samples, each with unique composition, on single substrate [10].

Solution-Processed Libraries via Slot-Die Coating

Principle: Employs continuous mixing of precursor inks with programmable flow rates to create composition gradients [11].

Experimental Protocol:

- Ink Preparation: Formulate two precursor solutions with concentration of 0.5M in compatible solvents [11].

- Flow System Setup: Connect ink reservoirs to slot-die coater with precision syringe pumps; establish stable meniscus at coating head [11].

- Gradient Programming: Program pumps to linearly vary flow rates (e.g., Pump A: 100% to 0%, Pump B: 0% to 100%) over coating duration [11].

- Substrate Handling: Translate substrate under coating head at constant speed of 10mm/s; maintain heated bed at 60°C for solvent evaporation [11].

High-Throughput Characterization Workflows

The value of materials libraries is realized through correlated high-throughput characterization techniques that map composition, structure, and properties across the library.

Table 2: High-Throughput Characterization Techniques

| Characterization Method | Measured Parameters | Spatial Resolution | Application Example |

|---|---|---|---|

| Micro-X-ray Fluorescence (μ-XRF) | Elemental composition | 50-100μm | Mapping of Cu-Cr-Co ternary system [13] |

| X-ray Diffraction (XRD) Mapping | Crystal structure, phase identification | 100μm | Phase evolution in Fe-Pt libraries [3] |

| Scanning Droplet Cell | Electrochemical properties, corrosion | 1mm | Corrosion properties mapping [12] |

| Magneto-Optical Kerr Effect | Magnetic properties, coercivity | 100μm | Coercivity mapping in Fe-Pt films [3] |

| Spatially Resolved Spectroscopy | Optical properties, band gap | 50μm | Band gap mapping of semiconductors [10] |

Integrated Characterization Protocol:

- Composition Mapping: Perform μ-XRF scan with 100μm step size across entire library; quantify elemental composition using standard calibration [13].

- Structural Analysis: Conduct XRD mapping with equivalent step size; use automated phase identification through hierarchical clustering [13].

- Functional Property Screening: Employ appropriate property-specific techniques (e.g., scanning droplet cell for electrochemical properties, MOKE for magnetic properties) with spatial registration to composition and structure data [3] [12].

- Data Correlation: Register all characterization datasets to common coordinate system; create correlated database linking composition-structure-property relationships [1].

Data Analysis and Existence Diagram Construction

The multidimensional datasets generated through high-throughput characterization require specialized analysis approaches to extract meaningful patterns and construct predictive existence diagrams.

Data Analysis Protocol:

- Data Preprocessing: Normalize all datasets to common spatial grid; apply background correction and peak fitting to spectral data [13].

- Automated Phase Identification: Implement hierarchical clustering analysis of XRD patterns to identify distinct structural regions [13].

- Correlation Analysis: Apply multivariate statistical methods to identify relationships between composition, processing parameters, structure, and properties [1].

- Existence Diagram Generation: Visualize results as multidimensional maps with composition axes, color-coded properties, and symbol-coded structural phases [1].

- Validation: Compare identified phase regions with thermodynamic predictions; validate property measurements against standard samples [1].

Case Study: Cu-Cr-Co Combinatorial Investigation

A comprehensive example demonstrating the integrated application of these concepts can be found in the high-throughput investigation of the Cu-Cr-Co ternary system [13].

Experimental Design:

- Library Fabrication: Combinatorial multilayer thin-film covering complete ternary composition range using high-throughput ion beam sputtering [13].

- Thickness Control: Individual nanoscale monolayers deposited with controlled thickness ratios to achieve desired stoichiometry coverage [13].

Characterization Workflow:

- Composition Analysis: μ-XRF mapping confirmed complete coverage of ternary composition space [13].

- Structural Evolution: High-throughput synchrotron XRD mapping monitored phase formation as function of annealing temperature (300-700°C), time (5-60 minutes), and modulation period (5-50nm) [13].

- Data Analysis: Automated analysis employing hierarchical clustering techniques developed composition-structure map [13].

Key Findings:

- Structural evolution dependence on annealing parameters and modulation period established [13].

- Equivalent effects observed: reducing modulation period produced similar phase evolution to increasing temperature [13].

- Composition-structure map provided existence diagram for Cu-Cr-Co system under various processing conditions [13].

Essential Research Reagents and Materials

Table 3: Key Research Reagent Solutions for Combinatorial Thin-Film Studies

| Reagent/Material | Specification | Function | Application Example |

|---|---|---|---|

| Elemental Sputter Targets | 99.95% purity, 2-3" diameter | Source materials for thin-film deposition | Fe, Pt, Cu, Cr, Co targets for alloy libraries [13] [3] |

| High-Purity Si Wafers | 100mm diameter, thermally oxidized | Substrate for materials libraries | Provides uniform, inert surface for deposition [3] [10] |

| Ultra-High Purity Argon | 99.999% purity | Sputtering process gas | Maintains plasma while preventing target oxidation [13] |

| Annealing Atmosphere Gases | N₂, H₂, Ar mixtures | Controlled environment for thermal processing | Prevents oxidation during phase formation [13] [3] |

| Precursor Inks | 0.1-1.0M metal salts in compatible solvents | Solution-based library fabrication | Slot-die coated composition spreads [11] |

Advanced Applications and Future Perspectives

The integration of combinatorial synthesis with computational methods and materials informatics represents the cutting edge of high-throughput materials discovery [1]. Several promising directions are emerging:

Machine Learning Integration: The large multidimensional datasets generated through combinatorial experimentation are ideal for training machine learning models to predict new materials with targeted properties [11]. This creates a virtuous cycle where computational predictions guide experimental exploration, and experimental results refine computational models [1].

Multifunctional Materials Discovery: The methodology enables efficient screening for multiple properties simultaneously, crucial for identifying materials that must satisfy multiple functional requirements [1]. This approach recently led to the discovery of a noble-metal-free nanoparticulate electrocatalyst, CrMnFeCoNi, with catalytic activity for the oxygen reduction reaction [1].

Cross-Platform Validation: Integration of thin-film discovery with bulk materials development ensures that promising candidates identified in thin-film libraries can be translated to practical applications [1]. This bridges the gap between fundamental materials discovery and engineering application.

The continued development of high-throughput synthesis and characterization technologies, coupled with advanced data analysis methods, promises to accelerate the discovery and optimization of new materials for applications ranging from sustainable energy technologies to energy-efficient processes [1].

The development of new functional materials, crucial for advancements in energy, electronics, and other high-technology sectors, has traditionally been a slow process, often taking decades from conception to implementation. High-throughput thin film synthesis techniques have emerged as a powerful paradigm to accelerate this discovery cycle, reducing development time from years to months by integrating combinatorial synthesis, automated characterization, and data science into a cohesive workflow [14]. This integrated approach allows researchers to rapidly explore vast compositional landscapes and establish processing-structure-property relationships at an unprecedented scale.

This protocol details the application of this discovery workflow, framed within a broader thesis on high-throughput methodologies. It provides a detailed framework for the rapid exploration of complex material systems, using examples from refractory high-entropy alloys (RHEAs) and functional ceramics to illustrate key concepts [15] [16]. The workflow is particularly valuable for investigating multi-principal element systems where compositional variations significantly influence material properties.

Experimental Principles

The fundamental principle underlying this discovery workflow is the replacement of sequential, single-sample experimentation with parallel processing of numerous compositions synthesized simultaneously in a single materials library. This is achieved through combinatorial synthesis techniques that create continuous compositional gradients across a substrate [16] [17]. Each discrete region within this gradient functions as a distinct material sample, enabling the high-throughput assessment of structure and properties.

This methodology relies on the tight integration of three core components:

- Combinatorial Synthesis: Fabrication of thin-film materials libraries with controlled compositional spreads.

- Automated Characterization: Rapid, spatially-resolved measurement of microstructure, chemistry, and functional properties across the library.

- Data Integration and Machine Learning: Management and analysis of large, multi-modal datasets to extract meaningful patterns and predictive models [4] [18].

A critical consideration when employing thin-film libraries is their predictive validity for bulk material behavior. Studies on NbMoTaTiV refractory high-entropy alloys have shown that while thin films can accurately capture phase formation trends, they may exhibit significant microstructural differences (e.g., ultrafine columnar grains versus coarse equiaxed grains in bulk) that influence mechanical properties [15]. Consequently, high-throughput screening should be viewed as an effective method for identifying promising compositional regions, with final candidate validation requiring bulk synthesis and testing.

Materials and Equipment

Research Reagent Solutions

Table 1: Essential Materials for High-Throughput Thin Film Workflows

| Item | Function | Application Example |

|---|---|---|

| Elemental or Alloy Sputtering Targets | High-purity sources for deposition; multiple targets enable combinatorial co-sputtering. | Deposition of Nb, Mo, Ta, Ti, V for RHEA libraries [15]. Al, Sc, Y targets for piezoelectric nitrides [18]. |

| Inert Substrates (e.g., Thermally Oxidized Si Wafers) | Provide a clean, uniform, and flat surface for film growth; minimal chemical interaction with deposited material. | Standard substrate for Ni-Ti-Cu-V shape memory alloy libraries [17]. |

| High-Purity Inert Sputtering Gas (Argon) | Ionized gas used to dislodge atoms from target surfaces in a vacuum environment. | Standard practice for magnetron sputtering in multiple studies [16] [18]. |

| Reactive Sputtering Gases (e.g., N₂, O₂, PH₃) | Introduce non-metallic elements into the growing film to form nitrides, oxides, or phosphides. | PH₃ used in reactive sputtering to form Zintl phosphide semiconductors (CaZn₂P₂) [18]. |

Required Equipment

- Combinatorial Magnetron Sputtering System: Equipped with multiple (typically 4-8) cathodes and capability for substrate rotation/positioning to generate compositional gradients [16] [18]. High-Power Impulse Magnetron Sputtering (HiPIMS) attachments are advantageous for achieving high-quality, textured films.

- High-Throughput Characterization Suite:

- X-Ray Fluorescence (XRF): For rapid, spatially-resolved compositional mapping [18].

- Automated X-Ray Diffraction (XRD): For crystal structure and phase identification across the library [4] [17].

- Automated Nanoindentation System: For mapping mechanical properties (hardness, modulus) [4] [18].

- Spectral and Electrical Measurement Probes: For optoelectronic properties (UV-Vis, photoluminescence, van der Pauw method) [18].

- Data Management Infrastructure: A dedicated database, such as the High-Throughput Experimental Materials Database (HTEM-DB), is essential for storing, managing, and making data Findable, Accessible, Interoperable, and Reusable (FAIR) [18].

Step-by-Step Protocol

Combinatorial Library Design and Synthesis

This section outlines the procedure for fabricating a compositionally graded thin-film library via magnetron co-sputtering.

Procedure:

- Define Compositional Space: Identify the elemental system and the range of compositions to be explored. For a quinary RHEA system like NbMoTaTiV, this involves deciding the relative ratios of the five elements [15].

- Substrate Preparation: Clean a thermally oxidized silicon wafer (or other chosen substrate) using standard solvent cleaning (e.g., acetone, isopropanol) in an ultrasonic bath to remove organic contaminants. Dry with a stream of inert gas (e.g., N₂) and mount the substrate in the sputtering system's holder [17].

- Target and Substrate Loading: Load high-purity elemental or alloy targets into the magnetron sources. Place the prepared substrate into the chamber, ensuring proper alignment relative to the targets to achieve the desired gradient geometry.

- Establish Vacuum Environment: Pump down the deposition chamber to a high vacuum base pressure (typically < 1 × 10⁻⁶ mbar) to minimize contamination during deposition.

- Define Sputtering Parameters:

- Introduce high-purity Argon gas to a working pressure of ~1-5 × 10⁻³ mbar.

- Set the power for each magnetron source (DC, RF, or HiPIMS). Varying the power among targets is the primary method for controlling the composition gradient.

- Program the substrate motion (static, rotation, or oscillation) to achieve the desired thickness and compositional homogeneity or gradient [16] [18].

- Execute Co-sputtering Deposition: Initiate plasma ignition and deposit the film for a predetermined time to achieve the target thickness (typically hundreds of nanometers to microns). For reactive deposition (e.g., nitrides, phosphides), introduce controlled flows of reactive gases like N₂ or PH₃ [18].

- Post-deposition Processing: After deposition is complete, allow the sample to cool under vacuum before venting the chamber with inert gas. Retrieve the materials library for characterization. Annealing treatments may be applied to study phase stability or homogenization.

High-Throughput Characterization and Data Collection

Once synthesized, the library undergoes automated characterization to collect processing-structure-property data.

Table 2: Key High-Throughput Characterization Techniques

| Technique | Property Measured | Throughput Method | Application Example |

|---|---|---|---|

| X-Ray Fluorescence (XRF) | Chemical Composition | Spatial mapping with automated XY stage. | Direct measurement of composition at thousands of points on a library [18]. |

| X-Ray Diffraction (XRD) | Crystal Structure, Phase | Automated mapping with a fast detector. | Identification of BCC/FCC phases in RHEAs; phase solubility in AlScYN [15] [18]. |

| Automated Nanoindentation | Hardness, Modulus | Grid-based testing with spatial registration. | Screening mechanical properties of CuNi and RHEA libraries [15] [18]. |

| Temperature-Dependent Resistance | Phase Transformation | In-situ heating stage with electrical probes. | Detecting martensitic transformation in shape memory alloy libraries [17]. |

Procedure:

- Compositional Mapping: Use automated XRF to create a quantitative composition map of the entire library. This dataset will serve as the foundational coordinate system, linking every measurement location to its specific chemical composition [18].

- Structural Characterization: Perform automated XRD mapping across the library with a step size appropriate for the compositional gradient. This identifies crystalline phases, crystal structure, texture, and estimates grain size.

- Functional Property Screening:

- Mechanical Properties: Use an automated nanoindentation system with a calibrated tip (e.g., Berkovich) to perform a grid of indents. The number and distribution of indents should be optimized for statistical reliability and spatial coverage [18].

- Functional Properties: Employ other automated or semi-automated techniques relevant to the target application. For piezoelectric materials, this could be a laser interferometer to map the clamped d₃₃ coefficient [18]. For optoelectronic materials, use photoluminescence or UV-Vis mapping systems.

Data Management, Analysis, and Machine Learning

The final stage involves synthesizing the multi-modal datasets to extract knowledge and predictive models.

Procedure:

- Data Ingestion and Curation: Ingest all raw and processed data (XRF, XRD, nanoindentation, etc.) into a centralized, structured database like the High-Throughput Experimental Materials Database (HTEM-DB). Ensure all data points are linked via their spatial coordinates and composition [18].

- Data Preprocessing: Clean the data, handle missing values, and normalize features as necessary. For XRD patterns, this may involve background subtraction and peak fitting.

- Exploratory Data Analysis and Visualization:

- Create phase diagrams by plotting compositional regions against identified crystal structures from XRD [17].

- Generate property contour maps (e.g., hardness, band gap) overlaid on the composition space.

- Machine Learning Modeling:

- Use the curated dataset to train machine learning models. Common tasks include:

- Validate model performance using hold-out test sets or cross-validation.

- Model Deployment and Validation: Use the trained model to predict promising new compositions outside the original library. Validate these predictions through targeted synthesis and characterization, closing the discovery loop and refining the model.

Anticipated Results and Analysis

Successful implementation of this protocol will yield a comprehensive dataset mapping composition to structure and properties for the targeted material system. A primary output is a phase map, such as for a Ni-Ti-Cu-V system, where specific compositions exhibiting a shape memory effect and near-zero thermal hysteresis can be identified [17].

Analysis of mechanical screening data will reveal trends, such as a general correlation between nanohardness in thin-film RHEAs and bulk Vickers hardness. However, researchers should anticipate and account for discrepancies, where the highest thin-film hardness may not predict the highest bulk yield strength due to microstructural differences like segregation in bulk materials [15].

The ultimate result is a data-driven hypothesis for new, improved compositions. For instance, in piezoelectric AlScN, the workflow can reveal that co-doping with Y increases the solubility limit of Sc and enhances the clamped d₃₃ coefficient, pinpointing optimal (Sc+Y) concentrations for maximum performance [18].

Troubleshooting and Optimization

- Poor Compositional Control: If the achieved composition gradient does not match the design, use a Python-wrapped simulation tool like SIMTRA to model the deposition profile from multiple magnetrons and optimize power and positioning parameters before the next experimental run [18].

- Weak or Absent XRD Peaks: This indicates poor crystallinity or amorphous phases. Increase the substrate temperature during deposition or implement a post-deposition anneal. Using HiPIMS with metal-ion synchronized biasing can significantly improve texture and crystallinity without substrate rotation [18].

- High Noise in High-Throughput Data: For automated nanoindentation, ensure an optimal number of indents per region is used to balance statistical reliability with experimental time. A systematic study on a CuNi library can help define this balance [18].

- Data Management Challenges: If integrating data from multiple techniques becomes cumbersome, strictly adhere to the FAIR data principles from the project's outset and utilize containerized applications (e.g., via NREL's HERO platform) to standardize analysis pipelines and improve reproducibility [18].

Fabrication Platforms and Breakthrough Applications in Energy and Biomedicine

Physical Vapor Deposition (PVD) encompasses a range of vacuum-based coating techniques essential for depositing high-performance thin films. Within high-throughput thin film synthesis research, techniques like Magnetron Co-Sputtering and Multi-Arc Ion Plating are pivotal for the rapid exploration of new materials, significantly accelerating the development cycle and reducing costs associated with conventional methods [19]. These methods enable the fabrication of composition spread alloy films (CSAFs), allowing researchers to efficiently screen a vast compositional landscape from a single deposition experiment [19]. This application note details the operational principles, standardized protocols, and key applications of these two techniques, providing a framework for their implementation in a high-throughput research environment.

Magnetron Co-Sputtering and Multi-Arc Ion Plating are both versatile PVD methods, but they differ fundamentally in their mechanisms and the characteristics of the resulting films.

Magnetron Co-Sputtering utilizes multiple solid targets (e.g., metals, alloys) simultaneously. A plasma, sustained by an inert gas like argon, is confined near the targets by magnetic fields. Ions from this plasma bombard the targets, ejecting atoms that then travel to and condense on the substrate [20] [21]. By controlling the power applied to each target and the geometrical arrangement, a film with a controlled compositional gradient can be deposited [19].

Multi-Arc Ion Plating employs a high-energy electric arc that strikes the surface of a cathode target, locally vaporizing and ionizing the material to create a dense plasma cloud [22]. These ions are then accelerated by an electric field towards the substrate, resulting in a film with very high adhesion and density [19] [22].

The table below provides a direct comparison of these two techniques.

Table 1: Comparative Analysis of Magnetron Co-Sputtering and Multi-Arc Ion Plating

| Feature | Magnetron Co-Sputtering | Multi-Arc Ion Plating |

|---|---|---|

| Fundamental Principle | Momentum transfer from ion bombardment ejects target atoms [21]. | High-current arc vaporizes and ionizes target material [22]. |

| Plasma Ionization Degree | Low to moderate [20]. | Very high [22]. |

| Typical Deposition Rate | Moderate [20]. | High [19] [22]. |

| Film Adhesion | High [20]. | Very high due to intense ion bombardment [22]. |

| Film Density & Quality | High density, low defect density, uniform thickness [19]. | Very dense, but may contain micro-droplets [19]. |

| Composition Control (for CSAFs) | Excellent; wide composition range via power and angle control [19]. | Constrained; gradient requires large substrate area [19]. |

| Primary Advantages | Wide composition range, high-quality uniform films, wide applicability [19]. | High deposition rate, excellent adhesion, dense coatings [19] [22]. |

| Key Limitations | Lower deposition efficiency, relatively thin films [19]. | Presence of micro-droplets, narrower composition gradient [19]. |

Experimental Protocols

Protocol for High-Throughput Library Fabrication via Magnetron Co-Sputtering

This protocol outlines the steps for creating a combinatorial thin film library with a compositional gradient.

3.1.1 Workflow Diagram

The following diagram illustrates the key stages of the Magnetron Co-Sputtering process for high-throughput synthesis.

3.1.2 Step-by-Step Procedure

- Substrate Preparation: Clean the substrate (e.g., silicon wafer, glass) ultrasonically in successive baths of acetone, isopropanol, and deionized water. Dry with a nitrogen gun and load into the sputtering system [22].

- Target Loading: Load constituent elemental materials (e.g., Nb, Si, Cr) into separate confocal sputtering guns [19].

- System Pump-Down: Seal the chamber and initiate pumping to achieve a high base vacuum (typically < 6.0 × 10⁻⁴ Pa) to minimize contamination [22].

- Pre-sputtering Etching: Introduce argon gas and ignite a plasma to etch the substrate surface, removing native oxides and ensuring a clean, active surface for adhesion [22].

- Deposition Parameters:

- Gas Pressure: Maintain argon pressure between 0.1 - 1 Pa [20].

- Target Power: Independently control the power applied to each target to adjust the sputtering rate and final composition [19].

- Substrate Configuration: Position the substrate statically (without rotation) to allow for the natural formation of a compositional gradient across its surface [19].

- Deposition Time: Control time to achieve the desired film thickness.

- Film Growth: Initiate co-sputtering. The vapor fluxes from the different targets mix and co-deposit on the substrate, forming a CSAF [19].

- Post-deposition: After deposition, vent the chamber and retrieve the combinatorial library for characterization.

Protocol for High-Adhesion Coating via Multi-Arc Ion Plating

This protocol is optimized for depositing a dense, wear-resistant coating like Chromium Nitride (CrN).

3.2.1 Workflow Diagram

The workflow for Multi-Arc Ion Plating involves critical steps for surface activation and high-energy deposition.

3.2.2 Step-by-Step Procedure

- Loading: Securely fixture cleaned substrates onto a rotating holder. Load high-purity metal targets (e.g., Cr, Ti) [22].

- Pump-Down: Evacuate the chamber to an ultra-high vacuum (base pressure < 10⁻³ Pa) [22].

- Heating: Heat substrates to a temperature typically between 200°C and 450°C to enhance adatom mobility and film density [22].

- Ion Etching: Under an argon atmosphere, apply a high negative bias voltage to the substrates to attract argon ions, which sputter-clean and activate the surface [22].

- Arc Ignition & Deposition:

- Ignite a high-current electric arc on the surface of the metal target(s), creating a highly ionized plasma plume [22].

- For compound coatings (e.g., CrN), introduce a reactive gas like nitrogen.

- Apply a pulsed or DC bias voltage to the substrates to accelerate metal ions from the plasma, leading to high-energy bombardment and dense film growth [23].

- Coating Formation: The high-energy ions condense on the substrate, forming an exceptionally dense, well-adhered coating [22].

The Scientist's Toolkit: Essential Research Reagents and Materials

The table below lists key materials and their functions in PVD processes for high-throughput synthesis.

Table 2: Essential Research Reagents and Materials for High-Throughput PVD

| Item | Function / Role | Specific Examples & Notes |

|---|---|---|

| Elemental Sputtering Targets | Source materials for deposition in co-sputtering [19]. | High-purity (e.g., 99.99%) metals like Nb, Si, Ti, Cr. Configuration can be confocal [19]. |

| Alloy / Compound Arc Targets | Source materials for multi-arc ion plating [22]. | Cr, Ti, Zr, or pre-alloyed targets. Must withstand high-current arc. |

| High-Purity Process Gases | Inert gas for sputtering/etching; reactive gas for compound formation [22]. | Argon (sputtering gas), Nitrogen or Acetylene (for nitrides/carbonitrides) [22] [24]. |

| Specialized Substrates | Support for deposited films; choice depends on application (e.g., thermal stability) [19]. | Silicon wafers, glass slides, stainless steel (e.g., 316L) [19] [23]. |

| HiPIMS Power Supply | Enables high ionization for denser, higher-quality coatings [23]. | Used in advanced magnetron sputtering. Critical for coatings like enhanced Cr [23]. |

| Pulsed Bias Voltage Supply | Applies negative bias to substrates in multi-arc, attracting ions for denser growth [23]. | Key for synchronizing ion bombardment with plasma generation [23]. |

High-Throughput Characterization and Screening Methods

Rapid and automated characterization is crucial for evaluating the properties of combinatorial libraries.

- Microstructure Screening: Techniques like Scanning Electron Microscopy (SEM) and Transmission Electron Microscopy (TEM) are used to rapidly analyze grain size, film density, and identify phases across the composition spread [19]. For instance, TEM can reveal a unique shell-like microstructure in oxygen-doped Cr coatings, which is linked to improved mechanical properties [23].

- Compositional Analysis: Methods such as Energy-Dispersive X-ray Spectroscopy (EDS) coupled with SEM and X-ray Photoelectron Spectroscopy (XPS) are employed to map the elemental composition and chemical states across the gradient library [19] [23].

- Functional Property Screening:

- Mechanical Properties: Nanoindentation provides high-throughput measurement of hardness and elastic modulus across different compositions [19] [23].

- Corrosion & Oxidation Tests: Automated electrochemical testing and exposure to controlled environments can quickly identify compositions with superior corrosion resistance (e.g., low corrosion current density) or oxidation stability [19] [23].

Magnetron Co-Sputtering and Multi-Arc Ion Plating are two powerful, complementary techniques in the high-throughput thin film researcher's arsenal. Magnetron Co-Sputtering excels in creating broad, continuous compositional spreads for fundamental materials discovery, while Multi-Arc Ion Plating is ideal for depositing ultra-dense, high-adhesion functional coatings. By adhering to the detailed protocols and utilizing the essential toolkits outlined in this document, researchers can effectively leverage these PVD methods to accelerate the development and optimization of next-generation materials.

Thin solid films, with thicknesses ranging from a few nanometers to several micrometers, are fundamental components in numerous conventional and emerging technologies [25]. Solution-processed deposition methods involve the application of a liquid precursor—such as a colloidal ink or solution—onto a substrate, forming a thin liquid film that subsequently dries or undergoes sintering to form a thin solid layer [25]. These techniques are particularly attractive for their potential scalability, cost-effectiveness compared to vacuum-based methods, and compatibility with a wide range of materials including organic semiconductors, metal oxides, and nanomaterials [25].

The selection of an appropriate deposition method is critical for both research and industrial applications, as it influences film uniformity, thickness control, material usage efficiency, and ultimately, device performance. This document focuses on three prominent techniques: spin-coating, slot-die coating, and microfluidics, providing detailed protocols, comparative analysis, and practical implementation guidelines within the context of high-throughput thin film synthesis research.

Spin-Coating: Theory and Applications

Fundamental Principles

Spin-coating is a widely used technique for depositing uniform thin films onto flat substrates. The process involves depositing a small volume of coating solution onto a stationary or rotating substrate, which is then accelerated to high rotational speeds. Centrifugal force spreads the fluid radially outward, forming a uniform thin layer, while solvent evaporation simultaneously occurs, leading to the formation of a solid film [26]. The process can be divided into four distinct stages: Deposition (the solution is deposited onto the substrate), Spin-up (the substrate accelerates to its final speed, and fluid flows radially outward, driven by centrifugal force), Spin-off (excess liquid flows to the perimeter and is ejected from the surface), and Evaporation (the film thins primarily through solvent evaporation, becoming a solid film) [26].

The final thickness of the dry film (hf) is inversely proportional to the square root of the angular velocity (ω), as described by the relationship: [ h_f \propto \frac{1}{\sqrt{\omega}} ] A more detailed model considering solution viscosity (η), initial concentration (C₀), and solvent evaporation rate provides a comprehensive theoretical framework for predicting film characteristics [26].

Experimental Protocol for Spin-Coating

Materials and Equipment:

- Spin coater (capable of precisely controlling speed and acceleration)

- Flat, clean substrates (e.g., silicon wafers, glass slides, ITO-coated glass)

- Coating solution (prepared with appropriate solute concentration and solvent properties)

- Pipette or syringe for solution dispensing

- Solvent for cleaning

- Fume hood or controlled environment (to manage solvent vapors)

Step-by-Step Procedure:

Substrate Preparation: Clean the substrate thoroughly to remove particulate contamination and organic residues. Standard cleaning procedures include sonication in detergent solution, deionized water, acetone, and isopropanol, followed by oxygen plasma treatment or UV-ozone cleaning to enhance wettability.

Solution Preparation: Prepare a coating solution with the desired material dissolved in an appropriate solvent. Filter the solution through a 0.2-0.45 μm syringe filter to remove undissolved particles that could cause film defects.

Solution Deposition:

- For static deposition: Place the substrate on the spin coater chuck and dispense a sufficient volume of solution (typically 0.5-2 mL for a 4-inch substrate) at the center while the substrate is stationary. Ensure the solution covers approximately 50-75% of the substrate surface.

- For dynamic deposition: Start the rotation at a low speed (500-1000 rpm) and dispose the solution onto the center of the rotating substrate.

Spinning Process:

- Program the spin coater with a two-step process:

- Step 1 (Spread cycle): Low speed (500-1000 rpm) for 5-10 seconds to spread the solution uniformly.

- Step 2 (Thin film cycle): High speed (1500-6000 rpm, depending on desired thickness) for 20-60 seconds to achieve final thickness and promote solvent evaporation.

- Program the spin coater with a two-step process:

Drying and Post-Processing:

- Transfer the coated substrate to a hotplate for thermal annealing if required (temperature and duration depend on the material system).

- Perform all steps in a controlled environment (e.g., glovebox for air-sensitive materials).

Troubleshooting Guide:

- Streaks or Non-Uniformities: Check for substrate cleanliness, solution filtration, and environmental disturbances (vibrations, air currents).

- Orange Peel Texture: Often caused by rapid solvent evaporation; adjust solvent composition or increase ambient humidity control.

- Poor Adhesion: Improve substrate surface treatment and ensure compatibility between solution and substrate surface energy.

Applications and Limitations

Spin-coating is extensively used in research and development for fabricating thin films for organic photovoltaics, perovskite solar cells, organic light-emitting diodes (OLEDs), thin-film transistors, and various sensor applications [26] [25]. Its ability to produce highly uniform films with minimal training makes it ideal for rapid prototyping and small-batch production.

However, spin-coating has significant limitations for industrial scale-up, including low material utilization (typically ≤10%), restriction to batch processing, limitation to flat substrates, and difficulty in patterning or creating thickness gradients [26] [27]. These limitations have driven the adoption of alternative coating methods for manufacturing environments.

Slot-Die Coating: Scalable Thin Film Deposition

Fundamental Principles

Slot-die coating is a pre-metered coating technique that enables the continuous deposition of thin films with precise thickness control. In this process, the coating solution is pumped at a controlled flow rate through a precision-manufactured die head positioned above a moving substrate. The solution forms a meniscus between the die lip and substrate, resulting in the deposition of a uniform liquid film [27]. The wet film thickness is primarily determined by the solution flow rate and the substrate speed, following the relationship: [ \text{Wet Thickness} = \frac{\text{Flow Rate}}{\text{Substrate Width} \times \text{Substrate Speed}} ]

This method is particularly advantageous for roll-to-roll (R2R) manufacturing and can achieve high coating speeds with minimal material waste, making it economically viable for large-scale production [27].

Experimental Protocol for Slot-Die Coating

Materials and Equipment:

- Slot-die coater with precision translation stage

- Precision syringe pump or gear pump for solution delivery

- Coating solution with optimized viscosity and surface tension

- Flexible or rigid substrates

- Alignment fixtures

Step-by-Step Procedure:

Solution Preparation: Prepare coating solution with appropriate viscosity (typically 10-1000 cP for slot-die coating). Filter the solution to remove particulates that could clog the die head.

Die Head Setup and Alignment:

- Install the appropriate slot-die cartridge based on the desired coating width.

- Align the die head parallel to the substrate surface with a precise gap (typically 50-200 μm).

- Ensure the die head is perpendicular to the substrate movement direction.

System Priming:

- Fill the solution reservoir and tubing, then prime the system to remove air bubbles.

- Initiate solution flow until a steady meniscus is formed at the die lip.

Coating Process:

- Start substrate movement at the predetermined speed.

- Simultaneously activate solution flow at the calculated rate.

- Maintain stable meniscus throughout the coating process.

- For discontinuous patterns, implement precision start/stop protocols.

Drying and Post-Processing:

- Transfer the coated substrate to a drying zone or thermal annealing station.

- Implement multi-stage drying if required to prevent skin formation or defects.

Optimization Parameters:

- Coating Window Identification: Determine the range of flow rates and web speeds that yield defect-free films through systematic experimentation.

- Meniscus Stability: Optimize vacuum pressure (if applicable), die-substrate gap, and solution properties to maintain a stable meniscus.

- Solution Properties: Adjust viscosity, surface tension, and evaporation rate to match coating parameters.

Applications and Industrial Relevance

Slot-die coating has found significant applications in the manufacturing of large-area organic photovoltaics, perovskite solar modules, flexible OLED displays, thin-film batteries, and functional coatings [27]. Its compatibility with roll-to-roll processing enables high-throughput manufacturing of flexible electronic devices, making it a critical technology for printed electronics.

The technique's main advantages include high material utilization (>90%), continuous operation capability, precise thickness control, and compatibility with patterning through intermittent operation. Limitations include higher initial equipment cost, complexity in optimization, and extensive cleaning requirements between runs [27].

Comparative Analysis of Coating Techniques

Quantitative Comparison of Coating Methods

Table 1: Quantitative comparison of key parameters for solution-processed thin film deposition techniques

| Parameter | Spin Coating | Slot-Die Coating | Microfluidics |

|---|---|---|---|

| Typical Film Thickness Range | 10 nm - 10 μm [26] | 100 nm - 100 μm [27] | 100 nm - 500 μm (channel-dependent) |

| Material Utilization Efficiency | ~5-10% [26] | >90% [27] | >95% (precise volumetric delivery) |

| Scalability | Batch processing only [27] | Excellent (R2R compatible) [27] | Moderate (parallelization possible) |

| Relative Speed | Very fast (30-90 sec/ substrate) [26] | Fast (0.1-10 m/min) [27] | Slow to moderate (flow rate dependent) |

| Capital Cost | Low | High | Moderate to High |

| Thickness Control | Good (speed and concentration dependent) [26] | Excellent (flow rate and speed controlled) [27] | Excellent (precise flow control) |

| Patterning Capability | Limited (masks required) | Good (intermittent coating) | Excellent (direct patterning) |

| Suitable Substrates | Rigid, flat | Flexible and rigid | Various (depending on chip design) |

Table 2: Qualitative assessment of coating method characteristics

| Characteristic | Spin Coating | Slot-Die Coating | Microfluidics |

|---|---|---|---|

| Ease of Optimization | Simple [26] | Complex [27] | Moderate to Complex |

| Uniformity | Excellent (center to edge variation possible) [26] | Excellent [27] | Good to Excellent |

| Wastage | High [26] | Low [27] | Very Low |

| Process Control | Limited (mainly speed and time) [26] | Comprehensive (multiple parameters) [27] | Highly precise (multiple parameters) |

| Throughput | Low (batch processing) [27] | High (continuous) [27] | Low to Moderate |

Technique Selection Guidelines

Choosing the appropriate coating method requires careful consideration of research and production objectives: