Beyond Trial-and-Error: AI, Automation, and High-Throughput Strategies for Accelerating Functional Thin Film Discovery

This article provides a comprehensive guide for researchers and development professionals on modern strategies to accelerate the discovery of functional thin films.

Beyond Trial-and-Error: AI, Automation, and High-Throughput Strategies for Accelerating Functional Thin Film Discovery

Abstract

This article provides a comprehensive guide for researchers and development professionals on modern strategies to accelerate the discovery of functional thin films. We explore the foundational principles defining 'functional' performance in biomedical contexts, detail cutting-edge methodologies integrating AI and robotics, address common synthesis and characterization pitfalls, and establish robust frameworks for validation. The focus is on translating accelerated discovery from proof-of-concept to reliable, scalable pipelines for drug delivery, biosensing, and implantable device coatings.

What Makes a Thin Film 'Functional'? Defining the Target for Biomedical Innovation

This whitepaper, framed within a broader thesis on accelerated discovery platforms for functional thin films (FTFs), delineates the core technical distinctions between FTFs and conventional biomedical coatings. The convergence of precision deposition, nanostructured design, and high-throughput screening is catalyzing a paradigm shift from passive, monolithic coatings to active, multi-functional thin film systems. This guide provides researchers with the definitions, quantitative benchmarks, experimental protocols, and toolkit necessary to navigate this evolving landscape.

Core Definitions & Comparative Analysis

Defining Characteristics

Functional Thin Films (FTFs) are engineered material layers, typically sub-micron to a few microns thick, where composition, nanostructure, and interfacial properties are precisely controlled to elicit specific, active biological responses. Functionality is designed-in at the molecular or nano-scale.

Conventional Coatings are material layers applied to a substrate primarily for passive purposes—such as barrier protection, aesthetic improvement, or general biocompatibility—with less emphasis on nano-architectural precision or active bio-interaction.

Quantitative Comparison

Table 1: Core Differentiating Parameters between Functional Thin Films and Conventional Coatings

| Parameter | Functional Thin Films (FTFs) | Conventional Coatings |

|---|---|---|

| Primary Objective | Active biological modulation (e.g., controlled drug release, directed cell differentiation, anti-fouling via molecular repulsion). | Passive protection & general biocompatibility (e.g., corrosion barrier, lubricity, non-toxicity). |

| Thickness Range | 10 nm – 1 µm (often multilayered). | 1 µm – 100+ µm (often single-layered). |

| Structural Control | Atomic/molecular precision (e.g., nanoscale porosity, graded composition, organized nano-domains). | Macro/micro-scale homogeneity; minimal nano-architectural control. |

| Deposition Techniques | Atomic Layer Deposition (ALD), Pulsed Laser Deposition (PLD), Molecular Layer Deposition (MLD), RF Magnetron Sputtering. | Dip-coating, Spin-coating (basic), Spray-coating, Electroplating. |

| Key Performance Metrics | Release kinetics (ng/cm²/day), surface energy (mJ/m²), protein adsorption (ng/cm²), cell adhesion force (nN). | Adhesion strength (MPa), wear resistance (cycles), corrosion potential (V), bulk cytotoxicity (IC₅₀). |

| Integration with Discovery | Inherently compatible with high-throughput/combinatorial synthesis & screening platforms. | Typically developed via iterative, one-variable-at-a-time experimentation. |

Experimental Protocols for Key FTF Evaluations

Protocol: High-Throughput Screening of Anti-Fouling Polymer Brushes

Objective: To rapidly assess protein resistance of a combinatorial library of poly(ethylene glycol) (PEG)-based thin film gradients.

- Substrate Preparation: Clean silicon wafers are plasma-treated (O₂, 100 W, 2 min).

- Gradient Deposition: Using a custom microfluidic mixer, a solution of methoxy-PEG-silane (varying MW: 1k-10k Da) is flowed across the substrate, creating a continuous concentration/MW gradient. Incubate (60°C, 12 hrs).

- Protein Challenge: Incubate the gradient library in a solution of fluorescein isothiocyanate (FITC)-labeled fibrinogen (1 mg/mL in PBS, 1 hr, 37°C).

- Quantitative Analysis: Employ a automated fluorescence microscope scan. Quantify adsorbed protein (FITC intensity) versus position (MW/concentration). Data is fed into a machine learning model to predict optimal formulation.

Protocol: In Vitro Controlled Drug Release from Multilayered FTFs

Objective: To characterize the sustained release of a model therapeutic (e.g., Vancomycin) from a Layer-by-Layer (LbL) polyelectrolyte thin film.

- Film Fabrication: Using an automated dip-coater, alternately immerse a substrate in solutions of cationic chitosan (0.5 mg/mL, pH 5.0) and anionic vancomycin-loaded hyaluronic acid nanoparticles (1 mg/mL, pH 6.0). Rinse between dips. Repeat for 50 bilayers.

- Release Study: Immerse the coated substrate in 10 mL of phosphate-buffered saline (PBS, pH 7.4) at 37°C under gentle agitation.

- Sampling & Quantification: At predetermined intervals (1, 4, 8, 24, 48, 96 hrs), withdraw 1 mL of release medium and replace with fresh PBS. Analyze vancomycin concentration via High-Performance Liquid Chromatography (HPLC).

- Kinetic Modeling: Fit cumulative release data to models (e.g., Higuchi, Korsmeyer-Peppas) to determine release mechanism.

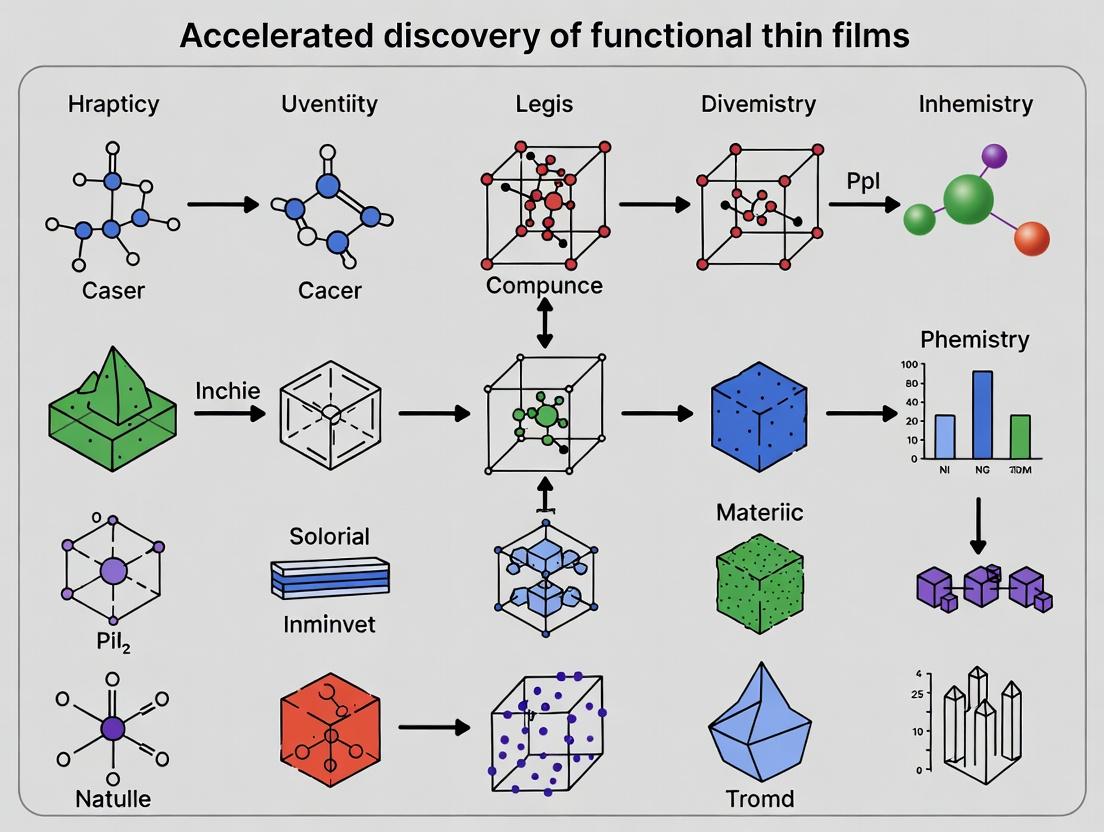

Visualizing the Accelerated Discovery Workflow for FTFs

Diagram 1: Closed-loop accelerated discovery cycle for FTFs (78 characters)

Signaling Pathway for a Bioactive FTF

Diagram 2: FTF-induced osteogenic signaling via topography (73 characters)

The Scientist's Toolkit: Key Research Reagent Solutions

Table 2: Essential Materials for FTF Research and Development

| Item | Function & Relevance |

|---|---|

| ALD Precursors (e.g., Trimethylaluminum, H₂O) | Enable atomic-scale, conformal deposition of metal oxide FTFs (e.g., Al₂O₃) for ultra-barrier or corrosion-resistant layers on implants. |

| Functional Silanes & Thiols (e.g., PEG-silane, RGD-thiol) | Form self-assembled monolayers (SAMs) on Au, Si, or TiO₂ to create precisely engineered bio-interfaces for cell adhesion or anti-fouling. |

| Polyelectrolytes for LbL (e.g., Poly(allylamine hydrochloride), Hyaluronic Acid) | Building blocks for constructing stratified, "smart" FTFs capable of pH-responsive drug release or mimicry of the extracellular matrix. |

| Fluorescently-Labeled Proteins (e.g., FITC-Fibrinogen) | Critical reagents for high-throughput, quantitative screening of protein adsorption—a key metric for anti-fouling FTF performance. |

| Combinatorial Sputtering Targets (Segmented) | Allow co-sputtering of multiple elements (e.g., Ti, Ag, Ta) in a single deposition run to create compositional gradient libraries for rapid alloy FTF discovery. |

| Cell Behavior Arrays (e.g., Pre-coated plates with FTF spots) | Commercial high-throughput platforms containing discrete FTF formulations for screening cellular responses like proliferation, differentiation, or toxicity. |

This technical guide details the critical Key Performance Indicators (KPIs) for evaluating functional thin films within the paradigm of accelerated discovery research. The systematic quantification of bioactivity, adhesion, degradation, and drug release kinetics is fundamental to the rapid screening, development, and deployment of advanced coatings for biomedical and pharmaceutical applications.

Key Performance Indicators: Definition & Significance

Bioactivity

Bioactivity refers to the ability of a thin film to elicit a specific, desirable response from biological systems, such as promoting cell adhesion, differentiation, or inhibiting bacterial colonization. It is a direct measure of functional efficacy.

Primary Quantitative Metrics:

- Cell Viability & Proliferation: Measured via MTT, AlamarBlue, or PrestoBlue assays.

- Cellular Differentiation: Quantification of lineage-specific markers (e.g., ALP for osteogenesis, Collagen II for chondrogenesis) via ELISA, qRT-PCR, or immunostaining.

- Antimicrobial Efficacy: Minimum Inhibitory Concentration (MIC), Minimum Bactericidal Concentration (MBC), or zone of inhibition measurements.

Adhesion

Adhesion assesses the mechanical integrity and stability of the thin film on its substrate under physiological conditions. It predicts long-term performance and failure modes.

Primary Quantitative Metrics:

- Critical Load (Lc): Measured via scratch testing (ASTM C1624).

- Adhesion Energy (G): Measured via tape test (ASTM D3359) or more quantitatively via double cantilever beam tests for robust films.

- Pull-off Strength (σ): Measured via tensile adhesion tests (ASTM D4541).

Degradation

Degradation profiles the rate and mode of film breakdown in a target environment (e.g., PBS, simulated body fluid, enzyme solutions). It governs release kinetics and functional lifetime.

Primary Quantitative Metrics:

- Mass Loss (%): Gravimetric analysis over time.

- Thickness Reduction (nm/day): Profilometry or ellipsometry measurements.

- Molecular Weight Change: For polymeric films, measured via Gel Permeation Chromatography (GPC).

- pH Change of Medium: Indicator of acidic/alkaline degradation products.

Drug Release Kinetics

Release kinetics describe the temporal profile of an active agent's elution from the film, determining therapeutic dosage and duration.

Primary Quantitative Metrics:

- Cumulative Release (%): Measured via UV-Vis spectroscopy, HPLC, or fluorescence of eluates.

- Release Rate (µg/cm²/day): Derivative of the cumulative release curve.

- Kinetic Model Fit: Parameters from models like Higuchi, Korsmeyer-Peppas, or zero/first-order kinetics.

Table 1: Benchmark KPI Ranges for Common Functional Thin Film Types

| Film Type (Example) | Bioactivity (Cell Viability % at 7d) | Adhesion (Critical Load, Lc in mN) | Degradation (Mass Loss % at 28d) | Drug Release (t50% in hours) |

|---|---|---|---|---|

| PLGA Nano-fibrous Coatings | 85-95% (osteoblasts) | 30-50 | 60-80 (PBS, 37°C) | 48-120 (model hydrophobic drug) |

| Chitosan-Hydroxyapatite Films | 90-110% (osteoblasts) | 50-100 | 15-30 (SBF, 37°C) | 12-24 (model protein) |

| Polyelectrolyte Multilayers (PEMs) | 70-90% (fibroblasts) | 15-40 (high humidity risk) | 5-20 (enzymatic) | 1-168+ (tunable via layers) |

| Silane-Based Hybrid Sol-Gels | 75-85% (endothelial cells) | 200-500 | <5 (PBS, 37°C) | N/A or very slow |

| Antimicrobial Peptide (AMP) Coatings | N/A (bacterial kill >99%) | 20-60 | Varies with peptide stability | Burst release <1h |

Table 2: Standard Experimental Conditions for KPI Assessment

| KPI | Standard Test Medium | Temperature | Duration | Key Analytical Instrumentation |

|---|---|---|---|---|

| Bioactivity | Cell culture medium (DMEM, α-MEM) | 37°C, 5% CO₂ | 1-21 days | Plate reader, qPCR cycler, fluorescence microscope |

| Adhesion | Ambient or PBS-humidified | 25°C | Minutes | Scratch tester, micro-indenter, tensile tester |

| Degradation | PBS (pH 7.4), SBF, or enzyme soln. | 37°C | 1-60 days | Analytical balance, GPC, profilometer |

| Release Kinetics | PBS (pH 7.4) or simulated fluids | 37°C, agitation | 1h-30 days | HPLC, UV-Vis spectrophotometer, fluorimeter |

Detailed Experimental Protocols

Protocol: High-Throughput Bioactivity Screening (Cell Proliferation)

- Objective: Quantify osteoblast proliferation on a 96-well plate coated with thin film variants.

- Materials: MC3T3-E1 cells, α-MEM medium, FBS, Pen/Strep, PrestoBlue reagent.

- Method:

- Seed cells onto coated wells at 5,000 cells/well in 100 µL complete medium.

- Incubate at 37°C, 5% CO₂ for 1, 3, and 7 days.

- At each time point, replace medium with 110 µL of 10% PrestoBlue in phenol-free medium.

- Incubate for 1 hour protected from light.

- Measure fluorescence (Ex 560 nm / Em 590 nm) using a plate reader.

- Normalize data to day 1 control film readings. Express as % relative proliferation.

Protocol: Quantitative Adhesion Testing (Micro-Scratch)

- Objective: Determine the critical load (Lc) for film delamination.

- Materials: Film-on-substrate coupon, progressive load micro-scratch tester, optical microscope.

- Method:

- Mount sample securely on the tester stage.

- Use a sphero-conical diamond stylus (tip radius 5-25 µm).

- Program a scratch length of 1-3 mm with a progressive load from 0 to 500 mN.

- Perform scratch at a constant speed of 1-5 mm/min.

- Simultaneously record acoustic emission and friction force.

- Post-test, analyze scratch track via optical microscopy to identify the precise point (Lc) of cohesive/adhesive failure.

- Repeat for n≥5 scratches per sample.

Protocol: Degradation Profiling (Gravimetric)

- Objective: Monitor mass loss of polymeric thin films in simulated physiological conditions.

- Materials: Pre-weighed film samples, PBS (pH 7.4), orbital shaker incubator, analytical microbalance.

- Method:

- Pre-dry films in a vacuum desiccator for 24h. Record initial dry mass (Mᵢ).

- Immerse individual films in 5 mL PBS in sealed vials.

- Place vials in an orbital shaker incubator at 37°C, 60 rpm.

- At predetermined time points (e.g., 1, 3, 7, 14, 28 days), remove samples (n=3 per point).

- Rinse gently with DI water to remove salts, and dry in a vacuum desiccator to constant mass.

- Record final dry mass (Mf).

- Calculate mass loss: % Mass Loss = [(Mᵢ - Mf) / Mᵢ] * 100.

Protocol: Drug Release Kinetics (HPLC-based)

- Objective: Characterize the release profile of a small molecule drug from a thin film.

- Materials: Drug-loaded film, PBS + 0.1% w/v Tween 80 (sink condition), HPLC with UV detector, calibration standards.

- Method:

- Immerse film in a known volume (V) of release medium (typically 1-10 mL) in a sealed vial at 37°C with gentle agitation.

- At each time point, withdraw the entire release medium and replace with fresh, pre-warmed medium to maintain sink conditions.

- Filter the aliquot (0.22 µm) and analyze drug concentration (C) via HPLC using a validated method.

- Calculate cumulative release: Cumulative Release (%) = [ (Σ (Cn * V) ) / Total Drug Load ] * 100.

- Fit the release data to kinetic models (e.g., Higuchi: Q = kH * t¹/²).

Visualizations

Diagram 1: Accelerated Discovery Workflow for Functional Films.

Diagram 2: Mechanisms and Modeling of Drug Release from Thin Films.

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for Functional Thin Film KPI Analysis

| Item | Function/Application | Example Vendor/Product |

|---|---|---|

| PrestoBlue / AlamarBlue Cell Viability Reagent | Resazurin-based fluorometric/colorimetric assay for high-throughput cell proliferation and cytotoxicity screening. | Thermo Fisher Scientific (PrestoBlue), Invitrogen (AlamarBlue) |

| ATCC Cell Lines (e.g., MC3T3-E1, NIH/3T3) | Standardized, well-characterized cells for reproducible bioactivity (proliferation, differentiation) assays. | American Type Culture Collection (ATCC) |

| Micro-Scratch Tester (with Acoustic Emission) | Measures critical load for film failure under a progressive load; essential for quantitative adhesion strength. | Anton Paar (Revetest), Bruker (UMT) |

| Ellipsometer | Precisely measures thin film thickness and refractive index in situ, critical for tracking degradation. | J.A. Woollam, Horiba Scientific |

| HPLC System with UV/Vis Detector | Gold-standard for quantifying drug concentration in release kinetics studies with high specificity and sensitivity. | Agilent Technologies, Waters Corporation |

| Simulated Body Fluid (SBF) Powder/Kits | Provides standardized ionic solution for studying film degradation and bioactivity (e.g., apatite formation). | Sigma-Aldrich (SBF Kit), Biorelevant.com |

| Poly(D,L-lactide-co-glycolide) (PLGA) Resins | Benchmark biodegradable polymer for controlled release films; available in various LA:GA ratios and MW. | Evonik (RESOMER), Sigma-Aldrich |

| Quartz Crystal Microbalance with Dissipation (QCM-D) | Real-time, label-free measurement of thin film mass, viscoelasticity, and degradation in liquid environments. | Biolin Scientific (Qsense) |

The discovery of novel functional thin films is a cornerstone of advanced materials science, impacting drug delivery, biomedical implants, sensors, and protective coatings. This whitepaper details the core material classes—Polymers, Lipids, Ceramics, and Nanocomposites—within a research framework prioritizing high-throughput synthesis, characterization, and screening. Accelerated discovery paradigms, such as combinatorial deposition and machine-learning-assisted property prediction, rely on a deep understanding of these foundational material systems and their processing-structure-property relationships.

Core Material Classes: Properties, Synthesis, and Applications

Table 1: Comparative Properties of Investigated Material Classes for Thin Films

| Material Class | Typical Young's Modulus | Critical Thin-Film Thickness Range | Degradation Time (Aqueous, if applicable) | Key Functional Properties |

|---|---|---|---|---|

| Polymers | 0.1 MPa - 10 GPa | 10 nm - 100 μm | Hours to years (controlled) | Flexibility, tunable permeability, stimuli-responsiveness |

| Lipids | 0.1 - 1000 MPa (bilayer) | 3 nm (bilayer) - 1 μm (multilamellar) | Minutes to days (dynamic) | Biocompatibility, self-assembly, barrier function |

| Ceramics | 50 - 1000 GPa | 20 nm - 10 μm | Highly inert or bioactive dissolution | High hardness, thermal stability, optical transparency |

| Nanocomposites | 1 MPa - 100 GPa (matrix-dependent) | 50 nm - 50 μm | Varies with matrix | Enhanced mechanical, electrical, or barrier properties |

Table 2: Common High-Throughput Deposition Techniques per Material Class

| Material Class | Preferred Deposition Methods | Throughput Potential | Key Process Parameters |

|---|---|---|---|

| Polymers | Spin-coating, Inkjet Printing, Spray-coating | Very High | Solvent volatility, polymer concentration, shear rate |

| Lipids | Langmuir-Blodgett, Vesicle Fusion, Spin-coating | Medium | Surface pressure, lipid phase, hydration |

| Ceramics | Sputtering, Pulsed Laser Deposition (PLD), Sol-Gel | Low-Medium | Power density, background gas, annealing temperature |

| Nanocomposites | Layer-by-Layer (LbL), Co-deposition, Sequential Printing | High | Dispersion quality, interfacial adhesion, loading fraction |

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials and Reagents for Thin Film Research

| Item | Function in Research | Exemplary Use Case |

|---|---|---|

| Poly(D,L-lactic-co-glycolic acid) (PLGA) | A biodegradable polymer for controlled-release films. | Fabricating drug-eluting coatings for implants. |

| 1,2-dioleoyl-sn-glycero-3-phosphocholine (DOPC) | A model phospholipid for forming fluid lipid bilayers. | Creating biomimetic membrane platforms for permeation studies. |

| Polyethylenimine (PEI) & Poly(sodium 4-styrenesulfonate) (PSS) | Polyelectrolyte pair for Layer-by-Layer (LbL) assembly. | Building nanocomposite thin films with nanoscale control. |

| Tetraethyl orthosilicate (TEOS) | Precursor for sol-gel derived silica ceramic films. | Producing mesoporous, high-surface-area coatings. |

| Functionalized Nanoparticles (e.g., Au, SiO2, graphene oxide) | Reinforcing or functional filler for nanocomposites. | Enhancing electrical conductivity or mechanical strength of polymer films. |

| Pluronic F-127 | Non-ionic surfactant for templating and dispersion. | Stabilizing nanoparticle inks for printing or creating porous structures. |

Detailed Experimental Protocols

Protocol: High-Throughput Spin-Coating of Polymer Nanocomposite Libraries

Objective: To create a gradient library of polymer/nanoparticle composite films for screening mechanical and wetting properties. Materials: Base polymer solution (e.g., 2% wt. PMMA in toluene), nanoparticle dispersion (e.g., 1 mg/mL SiO2 in toluene), programmable spin coater, masked substrates. Procedure:

- Gradient Dispensing: Use a syringe pump system to simultaneously dispense polymer solution and nanoparticle dispersion onto a single substrate in a linear gradient ratio (e.g., from 0 to 10% wt. nanoparticles across a 100 mm substrate).

- Dynamic Spreading: Immediately initiate a two-stage spin program: (i) 500 rpm for 10 s (spread), (ii) 3000 rpm for 60 s (thin and dry).

- Solvent Annealing: Place coated substrates in a sealed chamber with a shallow dish of solvent (e.g., toluene) for 5 minutes to promote nanoparticle rearrangement and polymer chain relaxation.

- Curing: Bake films at 80°C for 1 hour under vacuum to remove residual solvent.

- Characterization: Use automated ellipsometry for thickness mapping, nanoindentation for modulus gradient measurement, and goniometry for contact angle profiling.

Protocol: Formation of Supported Lipid Bilayers (SLBs) via Vesicle Fusion

Objective: To create a continuous, fluid lipid bilayer on a solid substrate for membrane-protein or permeability studies. Materials: DOPC or other phospholipids, small unilamellar vesicles (SUVs) prepared by extrusion (50 nm pore membrane), cleaned silica or glass substrate, Tris/NaCl buffer (10 mM Tris, 150 mM NaCl, pH 7.4). Procedure:

- Substrate Preparation: Treat substrate with oxygen plasma for 2 minutes to create a clean, hydrophilic surface.

- Vesicle Solution Preparation: Hydrate dried lipid film in buffer, vortex, and extrude through a 50 nm polycarbonate membrane 21 times to form SUVs. Final lipid concentration: 0.5 mg/mL.

- Incubation for Fusion: Pipette 200 µL of SUV solution onto the substrate mounted in a fluidic cell. Incubate at 60°C for 1 hour.

- Rinsing: Gently rinse the cell with 5 mL of warm buffer (37°C) to remove unfused vesicles and multilamellar structures.

- Validation: Confirm bilayer formation via fluorescence recovery after photobleaching (FRAP) for mobility (>1 µm²/s diffusion coefficient expected) or quartz crystal microbalance with dissipation (QCM-D) monitoring (characteristic frequency and dissipation shift).

Visualization of Workflows and Relationships

Accelerated Thin Film Discovery Workflow

SLB Formation via Vesicle Fusion Protocol

Within accelerated discovery programs for functional thin films, the linear, hypothesis-driven research paradigm represents a critical rate-limiting step. This whitepaper examines the technical and procedural constraints of sequential methodologies—from target identification and material synthesis to characterization and validation—contrasting them with emerging high-throughput, parallelized approaches. We present quantitative data on timelines and success rates, detail experimental protocols for both traditional and accelerated workflows, and provide a toolkit of reagents and platforms essential for modern discovery research.

Functional thin films—for applications in photovoltaics, solid-state batteries, bioactive coatings, and sensors—have historically been developed through sequential steps. Each stage (computational design, precursor synthesis, deposition, structural/functional characterization, and performance testing) must be completed and analyzed before initiating the next. This "waterfall" model, while rigorous, creates a fundamental bottleneck, severely limiting the exploration of complex composition spaces and multi-variable processing conditions.

Quantitative Analysis of the Bottleneck

The inefficiency of the sequential model is quantified below. Data is synthesized from recent literature on thin-film perovskite development, solid electrolyte discovery, and antimicrobial coating research.

Table 1: Timeline and Output Comparison: Sequential vs. Parallelized Workflows

| Metric | Traditional Sequential Workflow | High-Throughput Parallel Workflow | Acceleration Factor |

|---|---|---|---|

| Cycle Time (Design-to-Data) | 3 - 6 months | 1 - 2 weeks | 10x - 20x |

| Compositions Explored per Year | 10 - 50 | 1,000 - 10,000+ | 100x - 1000x |

| Key Parameter Space Dimensions | Typically ≤ 3 (e.g., ratio, temp, time) | 5+ concurrently (composition gradients, thickness, annealing) | N/A |

| Characterization Throughput | Manual, single-point measurement | Automated mapping (e.g., XRD, PL, conductivity) | 50x - 100x |

| Typical Success Rate (Hit to Lead) | ~1-2% | ~0.5-1% but on vastly larger scale | Net Lead Output >> 10x |

Table 2: Resource Allocation in a Sequential Discovery Project

| Phase | % Total Project Time | Primary Bottleneck Cause |

|---|---|---|

| Literature Review & Design | 15% | Manual curation, limited predictive models |

| Precursor Synthesis & Formulation | 25% | Batch synthesis, purification, quality control |

| Deposition & Processing | 20% | Single-sample tool setup, parameter optimization |

| Structural/Morphological Char. | 20% | Queue times for central facilities (SEM, TEM, XRD) |

| Functional Testing | 15% | Custom-built setups, low measurement parallelism |

| Data Analysis & Next Steps | 5% | Disparate data formats, manual correlation |

Deconstructing the Sequential Workflow: Protocols and Limitations

Protocol A: Traditional Sequential Sputtering of Ternary Oxide Films

- Aim: Discover a novel ternary oxide (A_x_B_y_C_z_O) with high ionic conductivity.

- Steps:

- Design: Fix one composition (e.g., x=0.5, y=0.3, z=0.2) based on literature analogs.

- Target Fabrication: Fabricate a single composite or segmented sputtering target via solid-state reaction (1150°C, 12 hrs) and hot pressing.

- Deposition: Sputter onto a single substrate using DC/RF magnetron sputtering. Optimize power, pressure, and temperature for this composition (multiple 2-hour runs).

- Characterization: Perform ex-situ XRD on the film (1-2 hrs instrument time + analysis). Perform cross-sectional SEM for thickness/morphology (sample preparation + 3 hrs).

- Functional Test: Deposit interdigitated electrodes via lithography (3-day process). Measure temperature-dependent impedance spectroscopy (8 hrs per temperature ramp).

- Analysis & Iteration: Based on results, propose a new composition and return to Step 1.

Core Limitations Identified:

- Idle Time: Characterization tools idle while deposition is optimized, and vice-versa.

- Insufficient Data Density: A single data point per cycle cannot map phase diagrams or identify narrow optimal regions.

- Correlation Challenges: Relating final properties to processing variables is confounded by run-to-run tool variability.

The Accelerated Alternative: An Integrated Parallel Workflow

The solution is a closed-loop, parallelized workflow integrating combinatorial materials synthesis, high-throughput characterization, and machine-learning-directed iteration.

Diagram 1: Sequential vs. Accelerated Discovery Workflow

Protocol B: Combinatorial RF Sputtering & High-Throughput Screening

- Aim: Rapidly map ionic conductivity across a ternary oxide phase space.

- Steps:

- Library Design: Use a ternary phase diagram to define a continuous composition spread library.

- Combinatorial Deposition: Use a multi-gun RF sputtering system with substrate rastering under shutters to create continuous compositional gradients across a 100mm wafer.

- Parallel Characterization:

- Structural: Automated XRD mapping (2θ from 20° to 60°) with a 2D detector across wafer (4 hrs total).

- Morphological: Automated SEM/EDS mapping at pre-defined grid points (6 hrs).

- High-Throughput Functional Test: Deposit a blanket top electrode. Use an automated micro-probe station with impedance spectroscopy at 100+ predefined grid points (8 hrs).

- Data Integration & ML: All spatialized data (composition, thickness, XRD phase ID, conductivity) is fed into a database. A Gaussian Process model identifies unexplored promising regions and recommends the next library.

The Scientist's Toolkit: Key Research Reagent Solutions

Table 3: Essential Tools for Accelerated Thin Film Discovery

| Category | Item/Platform | Function in Accelerated Workflow |

|---|---|---|

| Combinatorial Deposition | Multi-Target Sputtering System with Shutters | Creates continuous composition or thickness gradients on a single substrate. |

| Inkjet Printing/Pulse Laser Deposition (PLD) Library Tools | Precise, digital deposition of discrete composition libraries. | |

| High-Throughput Characterization | Automated XRD with 2D Detector & Mapping Stage | Rapid crystal structure and phase analysis across a sample library. |

| Robotic Raman/Photoluminescence Mapping System | Automated optical property mapping with micron resolution. | |

| Scanning Probe Microscopy (SPM) Array | Parallel measurement of electrical (c-AFM) or mechanical properties. | |

| Functional Screening | Automated Micro-Probe Station with Switch Matrix | Enables sequential electrical testing (I-V, impedance) of hundreds of contacts. |

| Microfluidic Reactor Arrays | For testing catalytic or corrosion-resistant coatings under multiple fluid conditions. | |

| Data & Analysis | Laboratory Information Management System (LIMS) | Tracks sample lineage (precursors, synthesis conditions, location on wafer). |

| Cloud-Based Data Analysis Platform (e.g., Citrination, MatD3) | Manages heterogeneous data streams and applies ML for pattern detection. | |

| Reagents & Substrates | Patterned Multi-Electrode Substrates (e.g., 96-well format) | Pre-fabricated substrates for direct functional testing post-deposition. |

| High-Purity, Liquid Precursor Libraries | For spin-coating or inkjet printing; enables precise stoichiometric mixing. |

Visualizing the Data Integration Pathway

The core of acceleration is the automated flow from experiment to decision.

Diagram 2: Closed-Loop Data Integration Pathway

The traditional sequential methodology imposes an intrinsic discovery bottleneck ill-suited for the vast complexity of functional thin film research. By adopting integrated combinatorial synthesis, parallelized characterization, and data-driven autonomous loops, researchers can transition from linear, time-intensive cycles to parallel, knowledge-intensive exploration. This paradigm shift, as evidenced by the quantitative data and protocols presented, is not merely an acceleration but a fundamental enhancement of the scientific discovery process itself, enabling the exploration of previously intractable material spaces.

Within the accelerated discovery of functional thin films—a field critical for next-generation photovoltaics, batteries, and catalytic surfaces—a fundamental methodological evolution is underway. Historically, materials discovery relied on an Edisonian (or empirical) screening approach: synthesizing vast combinatorial libraries and testing them for desirable properties with minimal prior theoretical guidance. While successful, this path is resource-intensive and often fails to reveal underlying principles. The emerging paradigm is hypothesis-driven design, where first-principles calculations, mechanistic understanding, and data science guide targeted synthesis. This whitepaper details this shift, providing the technical framework for researchers and development professionals to implement a rational design cycle.

Core Paradigms Compared

Table 1: Edisonian Screening vs. Hypothesis-Driven Design

| Aspect | Edisonian (Empirical) Screening | Hypothesis-Driven Design |

|---|---|---|

| Philosophy | "Test everything" via high-throughput experimentation; discovery through brute force. | "Design intelligently" using models and prior knowledge to test specific hypotheses. |

| Theoretical Basis | Minimal or post-hoc; correlations may not imply causation. | Central and a priori; uses DFT, ML models, or established structure-property relationships. |

| Workflow Direction | Synthesis → Characterization → Data Analysis → (Possible) Insight. | Hypothesis → Predictive Model → Targeted Synthesis → Validation/Refinement. |

| Resource Efficiency | Low per-sample cost, but requires vast numbers of samples. High total resource use. | Higher initial investment in computation/modeling, but far fewer experimental iterations. |

| Output | Optimized material for a specific set of conditions; limited transferable knowledge. | Functional material and a validated mechanistic understanding for broader extrapolation. |

| Role of Data | Primary output; often large, complex, and under-utilized. | Used to train and validate predictive models; closed-loop learning. |

The Hypothesis-Driven Design Workflow for Functional Thin Films

The modern workflow integrates computation, synthesis, and characterization into an iterative cycle.

Diagram 1: Hypothesis-Driven Design Cycle

Key Experimental Protocols

Protocol: Hypothesis Generation via Density Functional Theory (DFT) Calculation

Objective: To predict the electronic structure (e.g., band gap, density of states) of a proposed thin film material prior to synthesis.

- System Setup: Select a crystallographic model (e.g., 2x2x2 supercell) for the base material (e.g., MAPbI₃ perovskite).

- Doping/Modification: Introduce dopant atoms (e.g., Sn substituting Pb) by replacing selected atoms in the supercell.

- Software Execution: Use a DFT code (e.g., VASP, Quantum ESPRESSO) with a hybrid functional (e.g., HSE06) for accurate band gaps.

- Calculation Parameters: Set plane-wave cutoff energy, k-point mesh density, and convergence criteria for total energy (< 1 meV/atom).

- Post-Processing: Extract the projected density of states (PDOS), band structure diagram, and formation energy of the doped system.

- Hypothesis Output: A quantitative prediction: "Sn doping at 12.5% will reduce the bandgap by ~0.3 eV and is energetically favorable."

Protocol: Targeted Synthesis via Pulsed Laser Deposition (PLD)

Objective: To epitaxially grow a thin film with precise stoichiometry and doping as predicted by DFT.

- Target Preparation: Fabricate a ceramic target via solid-state reaction of precursor powders (e.g., TiO₂, SrCO₃, La₂O₃) pressed and sintered to achieve the desired doping concentration (e.g., La:SrTiO₃).

- Substrate Preparation: Single-crystal substrate (e.g., (001) Nb:SrTiO₃) is cleaned ultrasonically in acetone, isopropanol, and dried.

- PLD Chamber Conditions: Evacuate chamber to base pressure (< 1 x 10⁻⁶ Torr). Heat substrate to 650-750°C in an oxygen background pressure of 100 mTorr.

- Ablation & Growth: Use a KrF excimer laser (λ = 248 nm) at a fluence of 1.5 J/cm², repetition rate of 5 Hz. Monitor growth in situ via Reflection High-Energy Electron Diffraction (RHEED) to control layer-by-layer deposition.

- Post-Growth Annealing: After deposition, cool the film in an oxygen atmosphere (300 Torr) to optimize oxygenation.

Protocol: High-Throughput Structural & Functional Characterization

Objective: To rapidly validate the synthesized film's structure and key functional property.

- High-Throughput XRD: Use a diffractometer with a 2D detector to perform rapid θ-2θ scans across a combinatorial library wafer. Automate phase identification via reference to the ICDD database.

- Automated Spectroscopic Ellipsometry: Map thickness and optical constants (n, k) across the wafer. Fit data to a Tauc-Lorentz model to derive the optical bandgap (Eg) for each composition point.

- Four-Point Probe Mapping: Automatically measure sheet resistance (Rₛ) on a grid across the doped film library using a motorized stage. Convert to resistivity using thickness data.

Table 2: Quantitative Data from a Hypothetical Doped Perovskite Screening Study

| Material Composition | Predicted Bandgap (eV) DFT (HSE06) | Measured Bandgap (eV) Ellipsometry | Measured Resistivity (Ω·cm) Four-Point Probe | Crystal Phase (XRD) |

|---|---|---|---|---|

| MAPbI₃ (Control) | 1.55 | 1.58 ± 0.02 | 1.2 x 10³ | Tetragonal |

| MA(Pb₀.₉₅Sn₀.₀₅)I₃ | 1.48 | 1.50 ± 0.03 | 8.5 x 10² | Tetragonal |

| MA(Pb₀.₉₀Sn₀.₁₀)I₃ | 1.42 | 1.45 ± 0.03 | 5.1 x 10² | Tetragonal |

| MA(Pb₀.₈₀Sn₀.₂₀)I₃ | 1.35 | 1.60 ± 0.05 | > 1 x 10⁶ | Phase-separated |

The Scientist's Toolkit: Key Research Reagent Solutions

Table 3: Essential Materials for Hypothesis-Driven Thin Film Research

| Item | Function & Rationale |

|---|---|

| High-Purity Sputtering/PLD Targets | Ensure precise stoichiometric transfer during physical vapor deposition. Doped targets (e.g., 1% Nb:TiO₂) are essential for testing doping hypotheses. |

| Single-Crystal Oxide Substrates (e.g., SrTiO₃, MgO, Al₂O₃ wafers) | Provide atomically flat, epitaxial templates for growing high-quality, oriented thin films, minimizing defects for fundamental property studies. |

| Metal-Organic Chemical Vapor Deposition (MOCVD) Precursors (e.g., Trimethylaluminum, Tetrakis(dimethylamido)titanium) | Enable controlled, vapor-phase delivery of cations for conformal and scalable film growth with precise composition control via flow rates. |

| High-Fidelity Chemical Dopants (e.g., La₂O₃ powder, SnI₄ pellets) | Source materials for introducing specific dopants into host lattices to systematically tune electronic or ionic properties as predicted. |

| Calibrated Ellipsometry Reference Samples | Accurately calibrate optical characterization tools, which are critical for non-destructive, rapid extraction of bandgap and thickness. |

| Combinatorial Library Masks | Used in sputtering to create discrete or continuous composition gradients on a single substrate, enabling high-throughput synthesis within one deposition run. |

Pathway to Accelerated Discovery

The final stage integrates validation data to refine the fundamental model, creating a self-improving discovery loop. The diagram below illustrates how functional characterization data feeds back to calibrate the initial computational hypothesis.

Diagram 2: Feedback Loop from Experiment to Theory

The Accelerator's Toolkit: High-Throughput Synthesis, AI, and Robotic Automation

High-Throughput Physical Vapor Deposition (PVD) and Chemical Vapor Deposition (CVD) Systems

1. Introduction: Catalysts for Accelerated Discovery Within the paradigm of accelerated materials discovery for functional thin films—spanning photovoltaics, superconductors, corrosion-resistant coatings, and bioactive surfaces—high-throughput (HT) synthesis is the critical first pillar. HT PVD and CVD systems enable the rapid, combinatorial fabrication of thin-film libraries with gradients in composition, thickness, and microstructure on a single substrate. This guide details the technical architecture, methodologies, and data-centric workflows that transform these systems from mere deposition tools into engines of discovery.

2. System Architectures & Comparative Data

| System Parameter | High-Throughput PVD (Sputtering/Evaporation) | High-Throughput CVD (Incl. ALD) |

|---|---|---|

| Primary Deposition Mechanism | Physical ejection of target material via plasma/thermal energy. | Chemical reaction of precursor vapors on heated substrate. |

| Typical Deposition Rate | 0.1 – 10 nm/s (sputtering); 0.1-5 nm/s (evaporation). | 1-100 nm/min (CVD); 0.05-0.2 nm/cycle (ALD). |

| Compositional Control | Co-sputtering from multiple targets, segmented targets, mask movement. | Precursor gas pulse sequencing, gradient flow mixers. |

| Lateral Gradient Creation | Substrate positioning relative to source, movable masks/shutters. | Gas injector geometry, temperature gradients across substrate. |

| Typical Library Size (on 100mm wafer) | 100s to 1000s of discrete compositions. | 10s to 100s of compositions, excellent uniformity within spot. |

| Best For Material Classes | Metals, alloys, nitrides, oxides (from compound targets). | Doped semiconductors, complex oxides, 2D materials, conformal coatings. |

| In-situ Monitoring Common | Quartz crystal microbalance (QCM), optical emission spectroscopy. | Laser interferometry, mass spectrometry, FTIR. |

| Annual Throughput (Estimated Films) | 50,000 - 200,000 unique samples with full automation. | 10,000 - 50,000 unique samples. |

3. Core Experimental Protocols

Protocol 1: HT Combinatorial Sputtering for Ternary Alloy Discovery Objective: To fabricate a continuous composition spread (CCS) library of a ternary metal alloy (e.g., Co-Fe-Ni) on a 100mm wafer.

- Substrate Preparation: Clean a SiO2/Si wafer via ultrasonic bath in acetone and isopropanol, followed by 5 min oxygen plasma treatment.

- System Configuration: Load three metallic targets (Co, Fe, Ni) in a confocal sputter gun arrangement angled towards the substrate center. Install a 3x3 cm2 movable shutter between targets and substrate.

- Deposition Programming: Program the shutter position to raster across the substrate plane. Independently control the power to each sputter gun (0-150W DC) according to a pre-calculated map, linking shutter position to target power ratios.

- Deposition: Pump chamber to base pressure <5x10-7 Torr. Introduce Ar sputtering gas at 3 mTorr. Execute the deposition program, typically lasting 30-60 minutes for a ~100 nm thick gradient film.

- Post-Processing: Anneal the library in a rapid thermal processing (RTP) system using a linear temperature gradient (200-600°C) across the wafer perpendicular to the composition gradient.

Protocol 2: HT Atomic Layer Deposition (ALD) for Doped Oxide Libraries Objective: To create a thickness and doping gradient library of ZnO:Al (AZO) on a 100mm wafer.

- Substrate Preparation: As in Protocol 1.

- System Configuration: Utilize a multi-channel gas injection manifold with separate lines for Diethylzinc (DEZ), Trimethylaluminum (TMA), and H2O. Substrate heater capable of uniform temperature (100-200°C).

- Gradient Programming: Employ a "dose-gradient" method. Program the precursor exposure times for TMA (dopant) to vary across the wafer by controlling pulse valve timing synchronized with substrate rotation/positioning. DEZ and H2O doses are kept constant.

- Deposition Cycle: One cycle consists of: DEZ pulse (0.1s) -> N2 purge (10s) -> H2O pulse (0.1s) -> N2 purge (10s). After every n ZnO cycles (e.g., n=10), a TMA pulse (0.02-0.1s gradient) is introduced, followed by standard purge. Repeat for 200 cycles.

- In-situ Monitoring: Use in-situ spectroscopic ellipsometry at a fixed point to monitor film growth per cycle.

4. The Scientist's Toolkit: Essential Research Reagent Solutions

| Item | Function in HT PVD/CVD Experiments |

|---|---|

| Segmented Sputtering Targets | Circular targets with different material sectors (e.g., 90° metal A, 90° metal B) to produce composition gradients via substrate rotation. |

| Programmable Multi-Aperture Shutters | Motorized shutters with patterned openings that modulate flux from sources to create lateral thickness/composition profiles. |

| Precursor Delivery Manifold (CVD) | Bank of solenoid valves and mass flow controllers for precise, sequential delivery of multiple precursor and dopant gases. |

| Heated Substrate Holder with Gradient Capability | Enables creation of temperature gradient libraries (e.g., 300°C to 500°C across wafer) to study phase formation. |

| Combinatorial Sample Library Holder | Custom plate for holding and aligning multiple small substrates (e.g., 10x10 mm) for discrete, high-density libraries. |

| In-situ Ellipsometry/Reflectometry Probe | For real-time monitoring of film thickness, roughness, and optical properties during deposition. |

| Sputter Gun Power Supply (Multi-Channel) | Independently controls power (and thus rate) for 4-6 guns simultaneously for co-deposition. |

| Load-Locked Transfer Module | Maintains vacuum integrity of main chamber while allowing rapid introduction/removal of substrate libraries. |

5. Data Integration & Workflow for Accelerated Discovery

Diagram Title: HT Thin-Film Discovery Closed Loop

6. Advanced Considerations & Future Outlook The next evolution integrates AI-driven experimental control. Bayesian optimization algorithms analyze real-time data to dynamically adjust deposition parameters (power, gas flow, temperature) during the creation of a single library, actively steering the synthesis towards regions of property space with maximal scientific interest (e.g., high ionic conductivity, specific bandgap). This represents the shift from high-throughput to intelligent-throughput, closing the discovery loop at unprecedented speeds. Interfacing HT synthesis with automated, multimodal characterization and a FAIR (Findable, Accessible, Interoperable, Reusable) data infrastructure is now the cornerstone of modern functional thin film research, directly accelerating the development of next-generation energy, electronic, and biomedical coatings.

Combinatorial Inkjet Printing and Spray Coating for Gradient Library Fabrication

Within the framework of accelerated discovery of functional thin films, combinatorial materials science is paramount for screening vast compositional and processing spaces. This technical guide details the integration of non-contact, drop-on-demand inkjet printing and automated spray coating to fabricate precise, two-dimensional gradient libraries. These libraries enable high-throughput characterization of properties such as conductivity, photoluminescence, or catalytic activity, drastically reducing development timelines for applications in photovoltaics, OLEDs, and sensor technologies.

The traditional "one-sample-at-a-time" approach is a bottleneck in functional materials research. Combinatorial gradient library fabrication involves creating a single substrate where material composition, thickness, or processing parameter varies continuously or in discrete steps across the surface. This allows for the mapping of material properties against these variables in a single experiment. Inkjet printing offers digital, picoliter-level control for discrete pixelated deposition, while spray coating provides a means for creating continuous gradients via overlapping spray passes with controlled translation.

Core Methodologies & Experimental Protocols

Instrumentation Setup

A typical integrated system consists of:

- Drop-on-Demand (DoD) Inkjet Printer: Piezoelectric printhead(s) with nozzle diameters of 20-80 µm, mounted on a high-precision XY translational stage.

- Ultrasonic Spray Coater: Nozzle with atomizer, mounted on a separate or the same XYZ stage.

- Substrate Holder: Heated stage with vacuum chuck for secure, flat mounting.

- Computer Control System: Custom software for synchronized stage motion and deposition trigger.

- Inert Atmosphere Enclosure (Optional): For processing air-sensitive materials (e.g., perovskites).

Protocol: Fabricating a Binary Composition-Thickness Gradient Library

Objective: Create a 50x50 mm substrate where the ratio of two precursor inks (A and B) varies along the X-axis, and the total film thickness varies along the Y-axis.

Materials Preparation:

- Precursor Inks: Formulate stable, filtered (<0.2 µm) dispersions or solutions of materials A and B. Key parameters: viscosity (8-20 cP), surface tension (28-35 mN/m), and volatile solvent fraction to ensure reliable jetting and fast drying.

- Substrate: Cleaned glass/ITO/Si wafer with appropriate surface treatment (e.g., oxygen plasma) to ensure wetting.

Procedure:

- Composition Gradient (X-axis) via Inkjet Printing:

- Load Ink A into one reservoir/channel and Ink B into another.

- Program the print pattern: A rectangular array of droplets.

- For each column i along the X-axis (0 to n columns), dynamically adjust the firing voltage/duration for each printhead to vary the effective droplet volume. The ratio is defined by:

Vol_A(i) = Total_Vol_per_Pixel * (1 - i/n)Vol_B(i) = Total_Vol_per_Pixel * (i/n) - Execute the print. The substrate stage moves in a raster pattern.

Thickness Gradient (Y-axis) via Spray Coating:

- After the printed ink droplets have dried, transfer the substrate to the spray coater stage (or use the same stage).

- Prepare a homogeneous mixture of A and B (e.g., 1:1 ratio) or a third material C.

- Program the spray nozzle to make passes along the X-axis.

- For each pass, the translational speed along the Y-axis is incrementally decreased. Slower speed = greater deposited material per unit area.

- The number of spray passes can also be varied along the Y-axis.

- Perform spray coating, with concurrent substrate heating (e.g., 60°C) to facilitate solvent evaporation and film formation.

Post-Processing:

- Anneal the entire library on a hotplate or in a furnace under controlled conditions (temperature, time, atmosphere).

Protocol: Process Parameter Gradient via Spray Coating

Objective: Investigate the effect of post-treatment intensity across a single-material film.

Procedure:

- Use spray coating to deposit a uniform film of material across the substrate.

- Mount the substrate on a temperature gradient hotplate, creating a linear temperature profile (e.g., 100°C to 400°C) along its length during annealing.

- Alternatively, use a staged UV-ozone or plasma treatment with masking to create a gradient in exposure time/intensity.

The Scientist's Toolkit: Research Reagent Solutions

| Item | Function | Example/Note |

|---|---|---|

| Piezoelectric DoD Printhead | Precisely ejects picoliter droplets via voltage-induced shape change. | Fujifilm Dimatix, Microfab JetDrive |

| Ultrasonic Spray Nozzle | Atomizes liquid into a fine mist via ultrasonic vibration for uniform coating. | Sono-Tek, Siansonic |

| High-Precision XY Stage | Provides micron-scale positional accuracy for deposition. | Aerotech, Physik Instrumente (PI) |

| Viscosity-Tuned Inks | Carrier fluids engineered for stable jetting and film formation. | Solvent blends (DMSO, 2-Methoxyethanol) with polymers/dispersants. |

| Heated Vacuum Chuck | Secures substrate and controls drying/kinetics during deposition. | Custom or commercially available from Ossila, Holmarc. |

| Automated Alignment System | Vision system to align deposition pattern to substrate features. | Keyence, Cognex cameras. |

| Inert Atmosphere Glovebox | Enables processing of oxygen/moisture-sensitive materials. | For perovskite, organic semiconductor libraries. |

Data Representation: Quantitative Parameters

Table 1: Key Printing & Coating Parameters and Typical Ranges

| Process | Parameter | Typical Range | Effect on Film |

|---|---|---|---|

| Inkjet Printing | Droplet Volume | 1-100 pL | Determines pixel resolution & material dose. |

| Jetting Frequency | 1-10 kHz | Affects fabrication speed. | |

| Substrate Temperature | 25-60°C | Controls drying rate, coffee-ring effect. | |

| Spray Coating | Nozzle Speed | 1-100 mm/s | Primary control for deposited thickness. |

| Flow Rate | 0.1-5 mL/min | Combined with speed sets deposition rate. | |

| Atomization Pressure | 0-5 psi (gas-assisted) | Affects mist density and pattern. | |

| Nozzle-Substrate Distance | 20-100 mm | Influences spot size and uniformity. |

Table 2: Characteristic Output of a Model Gradient Library

| Library Axis | Varied Parameter | Characterization Method | Measured Property Range (Example) |

|---|---|---|---|

| X-axis (0 to 50 mm) | ZnO:MgO Ratio (100:0 to 50:50) | EDX, XRD | Bandgap: 3.3 eV to 3.8 eV |

| Y-axis (0 to 50 mm) | Film Thickness | Profilometry | Thickness: 50 nm to 300 nm |

| Entire Library | Photocurrent Response | Automated 4-point probe | Current Density: 0.1 to 5.0 mA/cm² |

Visualized Workflows

Title: Workflow for Gradient Library Fabrication

Title: High-Throughput Characterization Data Flow

Integration into Accelerated Discovery Pipelines

The fabricated gradient libraries serve as the foundational input for closed-loop, autonomous discovery systems. Robotic stages automate characterization, generating vast datasets that feed machine learning models. These models predict new promising compositions or processing conditions, which are then synthesized and tested via the same combinatorial methods, iteratively accelerating the path to discovering optimal functional thin films for energy, electronics, and sensing applications. This methodology represents a critical transition from empirical, sequential research to a data-driven, parallelized discovery paradigm.

Integrating Robotic Platforms for Automated Spin-Coating and Layer-by-Layer Assembly

This whitepaper details the technical integration of robotic platforms to automate spin-coating and layer-by-layer (LbL) assembly, a cornerstone methodology for accelerated discovery in functional thin films research. Automating these repetitive, precision-demanding processes minimizes human variability, maximizes throughput, and enables the systematic exploration of complex parameter spaces—critical for advancing materials in energy storage, sensors, biomedical coatings, and drug delivery systems.

The quest for novel functional thin films—with tailored optical, electrical, mechanical, or bioactive properties—is limited by traditional manual fabrication methods. Robotic integration transforms this paradigm, allowing for high-throughput, reproducible, and data-rich experimentation. This guide provides the technical framework for implementing such automation within a research workflow aimed at rapid iteration and discovery.

Core Robotic Platform Architecture

A functional automated system integrates hardware for precise fluid handling, substrate manipulation, and environmental control with sophisticated scheduling software.

Key Hardware Components

- Robotic Arm or Gantry: Provides XYZ (and often rotational) movement for transferring substrates between stations. Critical specifications include precision (typically <±0.1 mm), payload, and repeatability.

- Automatic Spin Coater: Equipped with a programmable chuck, dispenser arm, and interlock for robotic loading/unloading.

- Liquid Handling System: A multi-axis syringe pump or piezoelectric dispenser for precise deposition of polymer solutions, nanoparticle suspensions, or ligand assemblies.

- Substrate Handling: Vacuum grippers or edge-contact end effectors to manipulate glass slides, silicon wafers, or other substrates without contamination.

- Washing/Drying Station: A basin with nozzles for dip or spray rinsing, integrated with a nitrogen gun for drying.

- Environmental Enclosure: Controls temperature and humidity, crucial for LbL assembly kinetics and film stability.

Software & Control

- Scheduling Software: Orchestrates the sequence of operations (e.g., pick substrate → spin coat layer A → wash → dry → dip in solution B → wash → dry → place in storage rack).

- Machine Vision: Used for substrate alignment (fiducial recognition) and defect inspection post-processing.

Detailed Automated Protocols

Protocol for Automated Spin-Coating of Hybrid Thin Films

This protocol is designed for creating gradient or combinatorial libraries of film thickness/composition.

- Substrate Loading: Robotic arm picks a clean substrate from a cassette and places it onto the vacuum chuck of the spin coater.

- Dispensing: The liquid handling system moves to a specified precursor solution vial, aspirates a set volume (e.g., 50–200 µL), and dispenses it onto the center of the static substrate. Dispense height and speed are controlled to minimize splashing.

- Spin Cycle: The chuck accelerates to a pre-programmed speed (500–5000 rpm) for a set time (20–60 s). Acceleration ramp and final speed are key variables.

- Curing/Post-processing: The arm transfers the coated substrate to a hotplate or UV curing station for a specified duration.

- Output: The finished substrate is placed into a labeled position in an output tray or microtiter-plate-style rack.

Protocol for Automated Layer-by-Layer (LbL) Assembly

This protocol automates the sequential adsorption of polyelectrolytes, nanoparticles, or biomolecules to build nanostructured films.

- Initialization: The system primes all fluidic lines with designated solutions (polycation, polyanion, rinse buffers).

- Adsorption Cycle: a. Dip in Solution A: The robotic arm holds the substrate and immerses it in the first adsorption solution for a programmed time (e.g., 2–10 minutes). Gentle agitation may be employed. b. Rinse: The substrate is transferred to the wash station, immersed or spray-rinsed in a gentle stream of deionized water (pH adjusted) for 1–2 minutes. c. Dry: A nitrogen knife or jet dries the substrate for a fixed time (15–30 s). d. Dip in Solution B: The substrate is immersed in the second adsorption solution. e. Rinse & Dry: Steps (b) and (c) are repeated.

- Iteration: Steps (a) through (e) are repeated for the desired number of bilayers (n). The system can alternate between more than two solutions for complex architectures.

- Final Processing: After n cycles, the film may be subjected to a final crosslinking step or annealing.

Data Presentation: Quantitative Performance Metrics

The following tables summarize key performance data from current automated thin film fabrication systems.

Table 1: Throughput & Reproducibility Comparison: Manual vs. Automated LbL

| Metric | Manual LbL | Automated Robotic LbL | Improvement Factor |

|---|---|---|---|

| Time per Bilayer | 15-20 min | 5-7 min | ~3x |

| Active User Time | 100% | <10% (monitoring) | >10x |

| Thickness Std. Dev. (10 bilayers) | ±8-12% | ±2-4% | 4-6x more consistent |

| Max Bilayers per Day (8h shift) | ~24-32 | 70-100 | ~3x |

Table 2: Impact of Automation on Experimental Design Space Exploration

| Parameter | Manual Method Range | Automated Robotic Platform Range | Potential Experiments |

|---|---|---|---|

| Spin Speed (rpm) | 3-5 discrete values | 10-50 gradient steps | Full thickness curves |

| Adsorption Time | 2-3 fixed times | 10+ stepped times (30s to 30min) | Kinetic studies |

| Solution Concentration | 2-3 concentrations | 5-10 concentrations via dilution | Isotherm mapping |

| Number of Layers | Few (due to fatigue) | 100s of layers | Thick film & stability studies |

The Scientist's Toolkit: Essential Research Reagent Solutions

| Item | Function in Automated Thin Film Fabrication |

|---|---|

| Programmable Spin Coater | Provides consistent, programmable rotation for film deposition and thickness control. Essential for creating uniform coatings. |

| Multi-axis Liquid Handler | Precisely aspirates, dispenses, and mixes precursor solutions, enabling complex gradients and combinatorial libraries. |

| Polyelectrolyte Solutions (e.g., PAH, PSS) | Building blocks for LbL assembly, enabling electrostatic film growth for barrier coatings or drug encapsulation. |

| pH & Ionic Strength Buffers | Control the charge density and conformation of polymers during LbL, directly affecting film structure and properties. |

| Functional Nanoparticle Inks (e.g., TiO2, Au, Graphene Oxide) | Enable creation of composite thin films with catalytic, conductive, or optical properties via spin-coating or LbL. |

| Non-reactive Substrate Grippers | Minimize contamination and damage during robotic transfer of delicate coated substrates (e.g., ITO glass, silicon wafers). |

| In-situ Quartz Crystal Microbalance (QCM) | Integrated into dip stations to monitor mass adsorption in real-time, providing immediate feedback for process control. |

| Automated Vision Inspection System | Scans for defects, measures contact angle, or verifies fiducial marks, ensuring quality control throughout the run. |

System Integration & Workflow Visualization

Automated Thin Film Fabrication Workflow

Automation's Role in Accelerated Discovery Logic

Integrating robotic platforms for spin-coating and LbL assembly is no longer a luxury but a necessity for research groups serious about accelerating the discovery and optimization of functional thin films. The technical framework provided here—encompassing hardware, detailed protocols, and performance data—offers a blueprint for implementation. This approach systematically converts empirical art into reproducible, data-driven science, directly powering the core thesis of accelerated discovery in advanced materials and drug development research.

This whitepaper, framed within the broader thesis on accelerated discovery of functional thin films, explores the paradigm of inverse design using machine learning (ML). Traditional materials discovery follows a forward path: a formulation is synthesized and its resulting function is measured. Inverse design reverses this process: starting with a target function or property, the model predicts the optimal formulation or structure. This approach is critical for accelerating the development of advanced thin films for photovoltaics, sensors, barrier coatings, and drug-loaded polymeric films.

Core Methodological Frameworks

The implementation of ML for inverse design in thin films relies on several key architectures:

- Generative Models: Variational Autoencoders (VAEs) and Generative Adversarial Networks (GANs) learn the underlying distribution of formulation space and can generate novel, valid candidates that satisfy target property constraints.

- Bayesian Optimization (BO): An iterative technique used to guide the experimental search for optimal formulations by building a probabilistic surrogate model (often Gaussian Process) of the property-function landscape.

- Inverse Graph Neural Networks (GNNs): For formulations where molecular or composite structure is crucial, GNNs operate on graph representations to predict the structure that yields a desired property vector.

- Conditional Deep Learning: Models are trained on paired data (formulation, function) and, at inference, conditioned on the desired function to output a formulation probability distribution.

Table 1: Performance Metrics of ML Models in Recent Thin Film Inverse Design Studies

| Model Type | Application (Thin Film Type) | Key Performance Metric | Result | Reference Year |

|---|---|---|---|---|

| Conditional VAE | Polymer Solar Cell (Active Layer) | Power Conversion Efficiency (PCE) of top model-predicted candidate | 12.4% (vs. 11.7% baseline) | 2023 |

| Bayesian Optimization | Perovskite LED (Emissive Layer) | Number of experiments to reach target external quantum efficiency (EQE) | Target achieved in 35 cycles (vs. ~150 for grid search) | 2024 |

| Inverse GNN | Metal-Organic Framework (MOF) Gas Separation Film | H₂/CO₂ selectivity prediction accuracy for novel structures | R² = 0.89 on hold-out test set | 2023 |

| Transformer-based Generator | Drug-Loaded Polymeric Nanoparticle Film | Formulation similarity to ideal Pareto-optimal front (drug release, stability) | >92% similarity score | 2024 |

Table 2: Common Feature Representations for Thin Film Formulations

| Feature Category | Description | Example Features | Dimensionality |

|---|---|---|---|

| Compositional | Ratios and identities of components | Solvent fraction, polymer molecular weight, doping concentration, drug load % | 10-100 |

| Processing | Synthesis and deposition conditions | Spin-coat speed, annealing temperature/time, solvent evaporation rate | 5-20 |

| Structural (Inferred) | Derived or calculated descriptors | Hansen solubility parameters, topological polar surface area, chain entanglement density | 50-500 |

Detailed Experimental Protocol: A Case Study

Protocol: High-Throughput Validation of ML-Predicted Photovoltaic Thin Films

This protocol details the experimental validation of formulations generated by a conditional VAE model for organic photovoltaic (OPV) active layers.

1. Objective: To synthesize and characterize a batch of 24 candidate donor-acceptor blend formulations predicted by the ML model to have a Power Conversion Efficiency (PCE) >11%.

2. Materials: (See "The Scientist's Toolkit" below).

3. Pre-Experimental ML Workflow:

- Model Input: Target property vector: PCE >11%, open-circuit voltage (Voc) >0.82V, processability score >0.8.

- Model Inference: Conditional VAE samples 24 formulations from the latent space conditioned on the target vector.

- Output: A list of 24 precise formulations specifying donor polymer (D), acceptor (A), D:A ratio, recommended solvent, and additive concentration.

4. Experimental Synthesis:

- Solution Preparation: For each candidate, prepare a 10 mg/mL total solute concentration in the recommended solvent (e.g., chloroform). Dissolve donor and acceptor materials according to the predicted weight ratio. Add a predicted volume % of 1,8-diiodooctane (DIO) additive if specified. Stir on a hotplate at 50°C for 12 hours.

- Substrate Preparation: Clean patterned ITO/glass substrates via sequential sonication in detergent, deionized water, acetone, and isopropanol (15 min each). Treat with UV-ozone for 20 minutes.

- Film Deposition: Deposit a hole-transport layer (PEDOT:PSS) via spin-coating at 4000 rpm for 40s, anneal at 150°C for 15 min. In a nitrogen glovebox, spin-coat the active layer solution at 2000 rpm for 60s. For formulations with DIO, perform solvent vapor annealing in a petri dish for 10 min. Thermally anneal on a hotplate at 100°C for 10 min.

- Electrode Evaporation: Transfer samples to a thermal evaporator. Deposit a LiF (1 nm) interlayer, followed by Al (100 nm) electrode through a shadow mask.

5. Characterization & Data Feedback:

- Current Density-Voltage (J-V) Measurement: Use a solar simulator (AM 1.5G, 100 mW/cm²) with a calibrated silicon reference cell to measure J-V curves for each device. Extract PCE, Voc, short-circuit current (Jsc), and fill factor (FF).

- Data Logging: Record all measured properties in a structured database, linking each data point to the exact input formulation and processing parameters.

- Model Retraining: Append the new high-quality experimental data (formulation → measured property) to the training dataset for subsequent model fine-tuning, closing the active learning loop.

Visualization Diagrams

Title: ML-Driven Inverse Design & Active Learning Loop

Title: Conditional VAE for Inverse Design Architecture

The Scientist's Toolkit

Table 3: Key Research Reagent Solutions for Thin Film Formulation Screening

| Item Name | Function/Description | Typical Example in OPV/Perovskite Research |

|---|---|---|

| Donor Polymer Solution | Electron-donating conjugated polymer, primary light absorber and hole transporter. | PBDB-T (Poly[(2,6-(4,8-bis(5-(2-ethylhexyl)thiophen-2-yl)-benzo[1,2-b:4,5-b']dithiophene))-alt-(5,5-(1',3'-di-2-thienyl-5',7'-bis(2-ethylhexyl)benzo[1',2'-c:4',5'-c']dithiophene-4,8-dione)]) in chlorobenzene. |

| Non-Fullerene Acceptor (NFA) Solution | Electron-accepting molecule, critical for charge separation. | ITIC-4F (3,9-bis(2-methylene-(3-(1,1-dicyanomethylene)-indanone))-5,5,11,11-tetrakis(4-hexylphenyl)-dithieno[2,3-d:2',3'-d']-s-indaceno[1,2-b:5,6-b']dithiophene) in chloroform. |

| Lead Halide Perovskite Precursor | Source of cations and anions for perovskite crystal formation. | 1.5M solution of FAPbI₃ (Formamidinium lead iodide) with MABr (Methylammonium bromide) in DMF:DMSO (4:1 v/v). |

| Solvent Additive | Modulates drying kinetics and morphology of the blend film. | 1,8-Diiodooctane (DIO), 1-Chloronaphthalene (CN), typically used at 0.5-3% v/v. |

| Hole Transport Layer (HTL) Solution | Facilitates hole extraction and improves anode contact. | PEDOT:PSS (Poly(3,4-ethylenedioxythiophene) polystyrene sulfonate) aqueous dispersion, filtered at 0.45 μm. |

| Electron Transport Layer (ETL) Solution | Facilitates electron extraction and improves cathode contact. | SnO₂ colloidal dispersion or [6,6]-Phenyl-C61-butyric acid methyl ester (PCBM) in chlorobenzene. |

| Anti-Solvent | Used in perovskite processing to induce rapid crystallization. | Chlorobenzene or ethyl acetate, dripped during spin-coating. |

This case study is framed within a broader research thesis aimed at accelerating the discovery of functional thin films for biomedical interfaces. The central hypothesis posits that integrating high-throughput combinatorial deposition, machine learning (ML)-driven design-of-experiments (DoE), and rapid in vitro biological screening can dramatically compress the timeline from material concept to validated prototype. Antimicrobial peptide (AMP)-coated films for implants serve as an ideal testbed, requiring the simultaneous optimization of multiple material properties (e.g., antimicrobial efficacy, mammalian cell biocompatibility, mechanical adhesion, stability) against a complex biological landscape. The traditional, sequential "one-variable-at-a-time" approach is prohibitively slow. This guide details the integrated, parallelized pipeline that constitutes the core of the accelerated discovery thesis.

Integrated High-Throughput Discovery Pipeline

The proposed workflow is a closed-loop cycle of design, fabrication, testing, and learning.

Diagram Title: Closed-Loop Accelerated Discovery Workflow for AMP Films

Core Experimental Methodologies

High-Throughput Combinatorial Film Fabrication

Objective: To synthesize a spatially addressable library of AMP-polymer composite films with gradients in composition and thickness.

Protocol:

- Substrate Preparation: 150 mm silicon wafers or polystyrene plates are cleaned via oxygen plasma treatment for 10 minutes to ensure uniform wettability.

- Co-Deposition Setup: Employ a custom or commercial combinatorial physical vapor deposition (PVD) / dip-coating system.

- Target 1: A polymer source (e.g., PLGA, chitosan, hydrophilic polyurethane) is loaded into one thermal evaporation crucible or solution reservoir.

- Target 2: The solid-phase synthesized AMP (e.g., GL13K, nisin, melittin derivative) is loaded into a separate, low-temperature organic evaporation source or is co-dissolved for inkjet printing.

- Library Design Execution: Using a shadow mask shuttle system or a programmable inkjet printer, co-deposit materials according to the ML-generated DoE matrix. Gradients are created by varying:

- Deposition rate (0.1 - 2.0 nm/s for polymer, 0.01 - 0.2 nm/s for AMP).

- Substrate position relative to sources.

- Solvent ratios in inkjet printing.

- Post-Processing: The library wafer is subjected to a mild vapor annealing step (e.g., ethanol vapor for 1 hour) to enhance film stability and peptide activity, then sterilized under UV light for 30 minutes.

High-Throughput Biological Screening

Objective: To quantitatively assess antimicrobial efficacy and mammalian cell biocompatibility in parallel for each film variant in the library.

Protocol A: Antimicrobial Activity (Modified ISO 22196)

- Sectioning: The combinatorial library wafer is aseptically sectioned into 5x5 mm coupons using a laser cutter or precision punch.

- Inoculation: Each coupon is inoculated with 20 µL of a bacterial suspension (Staphylococcus aureus ATCC 6538 or Pseudomonas aeruginosa ATCC 9027) in nutrient broth at ~1x10^6 CFU/mL.

- Incubation: Coupons are covered with a sterile, breathable film and incubated at 37°C and 90% RH for 24 hours.

- Recovery & Enumeration: Bacteria are recovered from each coupon by vortexing in 1 mL of neutralizing solution (e.g., D/E Neutralizing Broth) for 2 minutes. Serial dilutions are plated on agar and colonies are counted after 18-24 hours.

- Data Point: Log10 reduction is calculated relative to a negative control (bare substrate).

Protocol B: Mammalian Cell Cytocompatibility (ISO 10993-5)

- Cell Seeding: Human osteosarcoma (MG-63) or fibroblast (L929) cells are seeded directly onto the film coupons in 96-well plates at 10,000 cells/well in complete medium.

- Incubation: Cells are cultured for 48 hours at 37°C, 5% CO₂.

- Viability Assay: Media is replaced with fresh medium containing 10% AlamarBlue or PrestoBlue reagent. After 2-4 hours incubation, fluorescence (Ex560/Em590) is measured.

- Data Point: Viability is expressed as a percentage relative to a positive control (cells on tissue culture plastic).

Data Integration & Machine Learning Model Training

Objective: To create a predictive model linking film descriptors to performance outcomes.

- Feature Vector Assembly: For each film variant, compile a feature vector: [Polymer Dep Rate, AMP Dep Rate, Thickness, Water Contact Angle, AMP Sequence Descriptor (e.g., charge, hydrophobicity)].

- Target Variables: Corresponding Log10 Reduction (vs. S. aureus, P. aeruginosa) and Cell Viability (%).

- Modeling: A multi-output Gaussian Process Regression (GPR) or Random Forest model is trained on 80% of the data. Hyperparameters are optimized via cross-validation.

- Prediction & Optimization: The trained model predicts the performance landscape across the design space. Bayesian Optimization suggests the next set of promising film compositions for experimental validation, closing the discovery loop.

Table 1: Performance of Lead AMP-Coated Film Candidates from an Accelerated Screening Campaign

| Candidate ID | Polymer Matrix | AMP (Loading wt%) | Film Thickness (nm) | Log10 Reduction (S. aureus) | Log10 Reduction (P. aeruginosa) | Mammalian Cell Viability (%) | Adhesion Strength (MPa) |

|---|---|---|---|---|---|---|---|

| A-14 | Chitosan-PEG | GL13K (15%) | 120 ± 15 | 4.2 ± 0.3 | 3.8 ± 0.4 | 92 ± 5 | 28 ± 3 |

| B-07 | PLGA | Nisin (8%) | 85 ± 10 | 5.1 ± 0.2 | 2.1 ± 0.5 | 88 ± 6 | 32 ± 4 |

| C-22 | Hydrophilic PU | Mel4 derivative (12%) | 200 ± 20 | 3.5 ± 0.4 | 4.5 ± 0.3 | 95 ± 3 | 25 ± 2 |

| Control | Medical-Grade Ti | None | N/A | 0.1 ± 0.05 | 0.1 ± 0.05 | 100 (ref) | N/A |

Table 2: Acceleration Metrics: Traditional vs. Integrated Pipeline

| Metric | Traditional Sequential Approach | Accelerated Integrated Pipeline | Fold Improvement |

|---|---|---|---|

| Design-to-Data Cycle Time | 6-8 weeks per iteration | 1-2 weeks per iteration | 4-6x |

| Number of Formulations Tested | 10-20 per PhD project | 200+ per campaign | 10-20x |

| Primary Screening Throughput | 1-2 samples/day | 96-384 samples/day | ~100x |

| Key Parameters Optimized Concurrently | 1-2 | 5-7 (Comp, Thick, Morph, Activity, Tox) | 3-4x |

The Scientist's Toolkit: Key Research Reagent Solutions

Table 3: Essential Materials for AMP-Coated Film Discovery

| Item / Reagent | Function in Research | Example Product / Note |

|---|---|---|

| Combinatorial Deposition System | Enables parallel synthesis of film libraries with compositional gradients. | Custom-built PVD with multiple sources; or commercial inkjet printer (e.g., SonoPlot). |

| Solid-Phase Peptide Synthesizer | Provides custom, high-purity AMPs for integration into films. | CEM Liberty Blue or Biotage Initiator+ Alstra. |

| High-Content Screening Microscope | Automates imaging and analysis of bacterial killing and cell health on film arrays. | Celigo Image Cytometer or Thermo Fisher CX7. |

| AlamarBlue / PrestoBlue Cell Viability Reagent | Fluorometric assay for rapid, non-destructive measurement of mammalian cell health on films. | Thermo Fisher Scientific (DAL1025) or Invitrogen (A13261). |

| D/E Neutralizing Broth | Essential for halting antimicrobial action and recovering viable bacteria from test surfaces for accurate CFU counts. | Hardy Diagnostics (R112). |

| Oxygen Plasma Cleaner | Prepares substrate surfaces for uniform, adherent film deposition. | Harrick Plasma PDC-32G. |

| Atomic Force Microscope (AFM) | Characterizes nanoscale film topography, roughness, and mechanical properties (modulus, adhesion). | Bruker Dimension Icon or Cypher ES. |

| Quartz Crystal Microbalance with Dissipation (QCM-D) | Measures real-time adsorption kinetics and viscoelastic properties of AMP-polymer layers during deposition. | Biolin Scientific QSense Analyzer. |

| Machine Learning Software Suite | For DoE, predictive modeling, and data analysis (e.g., Python with scikit-learn, GPyOpt). | Anaconda Distribution with relevant libraries. |

Signaling Pathways for AMP-Bacteria Interaction on Film Surface

A key aspect of understanding AMP film efficacy is the mechanism of action on contact.

Diagram Title: Mechanisms of AMP Action from Coated Film Surface

This case study exemplifies the paradigm of accelerated discovery in functional thin films, specifically for biomedical applications. Traditional development cycles for polymer-based drug delivery systems are sequential and time-intensive. The integration of high-throughput synthesis, combinatorial deposition, and automated characterization platforms enables the rapid mapping of composition-structure-property-performance relationships. This work details a methodology for the rapid screening of pH-responsive polymer libraries, focusing on their swelling, degradation, and drug release kinetics under physiologically relevant pH conditions (e.g., pH 7.4 for blood and pH ~5.0-6.5 for tumor microenvironments or endosomes). The goal is to identify optimal film formulations for targeted, stimulus-responsive drug delivery.

Experimental Protocol: High-Throughput Synthesis & Characterization

2.1. Polymer Library Fabrication via Inkjet Printing/Spin-Coating Array

- Materials: A combinatorial library is created from monomers/pre-polymers. Common components include: