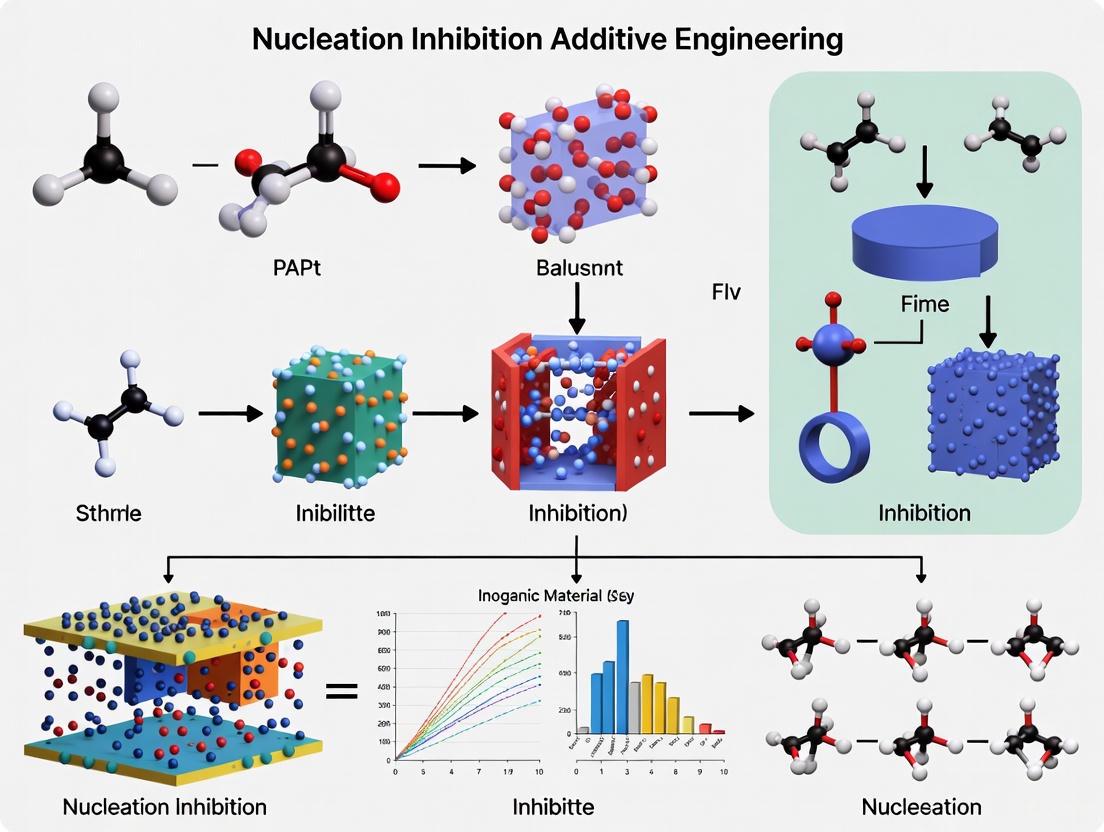

Nucleation Inhibition Additive Engineering: From Molecular Mechanisms to Biomedical Applications

This comprehensive review explores the rapidly evolving field of nucleation inhibition additive engineering, with specific focus on applications in pharmaceutical development and biomedical research.

Nucleation Inhibition Additive Engineering: From Molecular Mechanisms to Biomedical Applications

Abstract

This comprehensive review explores the rapidly evolving field of nucleation inhibition additive engineering, with specific focus on applications in pharmaceutical development and biomedical research. We examine fundamental thermodynamic and kinetic principles governing nucleation processes across diverse systems from small-molecule APIs to complex proteins. The article details innovative methodological approaches including computational screening, biomimetic additives, and tailored surface functionalization for controlling crystallization pathways. Practical optimization strategies address common challenges in inhibitor selection and synergistic combinations, while validation techniques from nanoscale characterization to predictive modeling provide frameworks for assessing inhibitor efficacy. By synthesizing recent advances across these domains, this work aims to equip researchers with both theoretical understanding and practical methodologies for developing next-generation nucleation inhibitors with enhanced specificity and performance in biomedical applications.

Fundamental Principles: Thermodynamics, Kinetics and Nucleation Pathways

Frequently Asked Questions (FAQs)

1. What is the Gibbs free energy barrier in nucleation, and why is it important? The Gibbs free energy barrier (( \Delta G^* )) is the maximum free energy that must be overcome for a stable nucleus of the new phase to form. It represents the energy cost of creating a new interface between the emerging phase and the solution. According to Classical Nucleation Theory (CNT), the total free energy change, ( \Delta G ), for forming a spherical nucleus of radius ( r ) is the sum of a unfavorable surface term (proportional to ( r^2 )) and a favorable volume term (proportional to ( r^3 )) [1]. The nucleation rate is exponentially dependent on this barrier ( \Delta G^* ) [1] [2]. This is crucial for inhibition engineering, as effective additives increase this barrier, dramatically slowing down the nucleation rate.

2. How does the critical nucleus form, and what is its significance? The critical nucleus is the smallest cluster of the new phase that has a higher probability of growing than dissolving [1] [2]. Clusters smaller than the critical size are unstable and tend to redissolve. Once a cluster reaches the critical size, its continued growth leads to a decrease in free energy, making the process spontaneous. The size of the critical nucleus, ( r^* ), and the work required for its formation, ( \Delta G^* ), are central to CNT [1] [3]. For a spherical nucleus, they are given by: ( r^* = \frac{2\gamma}{|\Delta gv|} ) and ( \Delta G^* = \frac{16\pi \gamma^3}{3(\Delta gv)^2} ) where ( \gamma ) is the interfacial free energy and ( \Delta g_v ) is the thermodynamic driving force (the Gibbs free energy difference per unit volume) [1] [3].

3. How do nucleation inhibitors work from the perspective of CNT? Nucleation inhibitors, or additives, work through kinetic and thermodynamic effects that increase the nucleation barrier[cite:7]. Mechanistically, they can achieve this by:

- Increasing Solubility: A higher solubility decreases the solution supersaturation, which directly reduces the thermodynamic driving force, ( \Delta gv ). Since ( \Delta G^* ) is inversely proportional to the square of ( \Delta gv ), this significantly increases the work of critical cluster formation [4].

- Adsorbing to Clusters: Additives can adsorb to the surface of pre-critical clusters, effectively raising the interfacial energy, ( \gamma ) [1]. As ( \Delta G^* ) is proportional to ( \gamma^3 ), a slight increase in surface tension causes a large increase in the energy barrier.

- Disrupting Molecular Assembly: Tailor-made inhibitors can bind to solute molecules and disrupt the specific intermolecular interactions necessary for the correct integration of molecules into the crystalline lattice, thereby impeding the growth of stable nuclei [4].

Troubleshooting Guides

Guide 1: Addressing Inconsistent Nucleation Rates in Inhibition Experiments

Problem: Measured nucleation rates show high variability or deviate significantly from theoretical predictions despite the presence of an inhibitor.

| Possible Cause | Diagnostic Steps | Solution |

|---|---|---|

| Unaccounted Heterogeneous Nucleation | Inspect container surfaces and substrate for crystals. Compare nucleation rates in differently treated vessels. | Use smaller containers with a higher surface-to-volume ratio to reduce heterogeneous sites. Employ surface passivation or select containers made of different materials. |

| Variations in Supersaturation | Monitor and tightly control temperature, as it strongly affects solubility and supersaturation. Precisely measure the solubility (c*) of your system with and without the additive [4]. | Pre-equilibrate all solutions to the experimental temperature. Use highly accurate dosing and temperature control systems. |

| Stochastic Nature of Nucleation | Perform a large number of identical induction time experiments (e.g., 50-100 runs) and analyze the data using classical probability distributions [4]. | Do not rely on a single or a few nucleation measurements. Use statistical analysis (e.g., cumulative probability distributions) to obtain a reliable, time-independent nucleation rate, J [4]. |

Guide 2: Evaluating and Selecting Effective Nucleation Inhibitors

Problem: Need a methodological framework to test and compare the efficacy of potential nucleation inhibitors.

| Experimental Goal | Key Measurable Parameters | Protocol & Analysis |

|---|---|---|

| Quantify Inhibition Potency | Induction Time (( t )) and Nucleation Rate (( J )) | Measure induction times at constant supersaturation and temperature with/without inhibitor. Use the relationship ( J = 1 / (t \cdot V) ) (for a large number of experiments) to calculate the nucleation rate. A potent inhibitor will cause a large increase in induction time and a decrease in J [4]. |

| Determine Thermodynamic Impact | Solubility (( c^* )) and Supersaturation (( S )) | Measure the solubility of the crystallizing compound in the presence of the inhibitor. Recalculate the supersaturation, ( S = c/c^* ). An effective inhibitor often acts as a "salting-in" agent, increasing solubility and thereby reducing the driving force for nucleation [4]. |

| Probe the Mechanism of Inhibition | Cluster Structure and Interactions | Use techniques like Dynamic Light Scattering (DLS) to detect the size and presence of pre-nucleation clusters. Employ Raman/IR spectroscopy and DFT calculations to investigate how the inhibitor binds to solute molecules and disrupts key interactions in the nascent crystal lattice [4]. |

Experimental Data & Protocols

The table below synthesizes key experimental findings from research on inhibiting monosodium urate monohydrate (MSUM) crystallization, a model system for pathological crystal formation [4].

| Parameter / Condition | Without Xanthine (Inhibitor) | With Xanthine (Inhibitor) | Impact & Significance |

|---|---|---|---|

| Solubility (( c^* )) | Baseline value | Significantly increased | Confirms a "salting-in" effect, reducing thermodynamic driving force (( \Delta g_v )) [4]. |

| Nucleation Rate (( J )) | Baseline rate | Dramatically decreased | Direct evidence of kinetic inhibition; the additive greatly increases the observed induction time [4]. |

| Inhibition Mechanism | N/A | Suppression of 2D sheet formation and 3D aromatic stacking | Identifies a specific molecular mechanism beyond classic CNT parameters, involving disruption of key crystal growth motifs [4]. |

Detailed Experimental Protocol: Induction Time Measurement

This protocol is adapted from methods used to study the inhibition of MSUM crystallization and can be adapted for other systems [4].

Objective: To determine the nucleation rate of a compound in the absence and presence of a potential nucleation inhibitor.

Materials:

- Research Reagent Solutions:

- Solute: The compound of interest (e.g., MSUM, a protein, an API).

- Inhibitor: The potential additive (e.g., xanthine, tailor-made inhibitors).

- Solvent: Appropriate buffer or solvent (e.g., 150 mM NaCl, pH 7.4 for physiological simulations).

- Equipment: Jacketed beaker, temperature-controlled circulator, magnetic stirrer, high-definition camera, glass vials.

Procedure:

- Solution Preparation: Prepare a supersaturated solution of the solute in the chosen solvent at an elevated temperature where solubility is high (e.g., 95-97°C). Agitate for 20+ minutes to ensure complete dissolution.

- Inhibitor Addition: For test experiments, dissolve a known concentration of the inhibitor in the solution.

- Temperature Quench: Quickly transfer a known volume (e.g., 50 mL) of the hot solution to a jacketed beaker maintained at the target crystallization temperature (e.g., 15°C).

- Monitoring: Agitate the solution gently (e.g., 60 rpm) and continuously monitor it with a camera. The onset of nucleation is marked by a clear-to-cloudy transition in the solution.

- Data Recording: Record the time from the moment of transfer to the moment of cloudiness as the induction time, ( t ).

- Replication: Repeat this experiment a large number of times (e.g., 50-100) to account for stochasticity.

Data Analysis:

- Plot the cumulative probability distribution, ( P(t) ), of the induction times.

- The nucleation rate ( J ) can be determined from the slope of a plot of ( \ln(1 - P(t)) ) versus ( t ), using the relation: ( \ln(1 - P(t)) = -JV(t - tg) ), where ( V ) is the volume and ( tg ) is the negligible growth time to detectable size [4].

The Scientist's Toolkit

Key Research Reagent Solutions for Nucleation Inhibition Studies

| Reagent / Material | Function in Experiment | Example from Literature |

|---|---|---|

| Tailor-Made Inhibitors (TMI) | Molecules designed to structurally mimic the crystallizing solute, allowing them to bind to growing clusters and disrupt the crystal lattice. | Xanthine used to inhibit monosodium urate monohydrate (MSUM) crystals by disrupting purine ring stacking [4]. |

| Precipitating Agents | Salts or polymers used to reduce solute solubility and induce a supersaturated state, the prerequisite for nucleation. | Salts like NaCl used in protein crystallization or to simulate biological ionic strength [4]. |

| Buffers | To maintain a constant pH, which can critically affect the charge state of the solute and inhibitor, thereby influencing molecular interactions. | Hepes buffer used to maintain pH at 7.4 for physiological relevance in MSUM studies [4]. |

| Divalent Cations | Can act as bridges between surfaces and solutes, promoting heterogeneous nucleation, or interact specifically with solutes. | Mg²⺠or Ca²⺠triggering 2D crystal nucleation of proteins on mica surfaces [5]. |

| Ldha-IN-9 | Ldha-IN-9, MF:C17H22BrNO4, MW:384.3 g/mol | Chemical Reagent |

| CM037 | CM037, MF:C21H25N3O3S2, MW:431.6 g/mol | Chemical Reagent |

Theoretical Framework Visualization

Gibbs Free Energy Change During Nucleation

Nucleation Energy Barrier This diagram illustrates the change in Gibbs free energy, ( \Delta G ), as a function of cluster size, ( n ). The curve shows the energy barrier, ( \Delta G^* ), that must be overcome to form a stable nucleus of critical size, ( n^* ) [1] [2].

Mechanism of Nucleation Inhibition

Inhibition Pathways This workflow shows how nucleation inhibitors act. They can either bind directly to forming clusters to disrupt their structure (kinetic inhibition) or increase the solubility of the solute, thereby reducing the thermodynamic driving force for nucleation [4].

In the broader context of nucleation inhibition additive engineering, controlling crystallization is fundamental to producing materials with desired properties in pharmaceutical, chemical, and materials science industries. The Metastable Zone Width (MSZW) represents the crucial range of supersaturation within which a solution remains metastable—crystallization does not occur spontaneously despite being supersaturated, but can be initiated through seeding [6] [7]. Understanding and manipulating the MSZW is particularly vital for engineering additives that inhibit nucleation, as it directly determines the operational window for controlled crystallization processes. A wider MSZW, often achieved through effective additive engineering, provides greater process stability against unintended nucleation, enabling the development of sophisticated drug delivery systems and high-purity materials [8] [9].

MSZW Fundamentals and Theoretical Background

Defining the Metastable Zone

The metastable zone is diagrammatically represented on a solubility-supersolubility diagram, which divides the solution state into three distinct regions [6]:

- Stable Zone: The area below the solubility curve where the solution is undersaturated, and crystallization is impossible.

- Metastable Zone: The region between the solubility curve (saturation limit) and the metastable limit curve (supersolubility) where spontaneous crystallization is improbable but crystal growth can occur.

- Labile Zone: The area above the metastable limit curve where spontaneous crystallization occurs readily.

The solubility curve consists of "clear points" where solid material completely dissolves, while the metastable limit curve consists of "cloud points" where crystal nucleation first becomes detectable [6]. Unlike the solubility curve, which is a thermodynamic property, the metastable limit is kinetically controlled and strongly depends on process parameters including cooling rate, agitation, solution history, and the presence of impurities or additives [6] [7].

Factors Influencing MSZW

Table: Key Factors Affecting Metastable Zone Width

| Factor | Effect on MSZW | Practical Implication |

|---|---|---|

| Cooling Rate | Higher cooling rates increase measured MSZW [6] [7] | Standardize cooling rates for reproducible measurements |

| Agitation/Stirring | Increased agitation typically decreases MSZW [6] | Maintain consistent mixing in experiments |

| Solution History | Previous temperature exposure affects MSZW [6] | Document and control solution thermal history |

| Impurities/Additives | Can significantly widen or narrow MSZW depending on functionality [6] [8] | Additives can be engineered to inhibit nucleation |

| Solution Volume | Larger volumes may decrease MSZW due to higher probability of nucleation [7] | Consider scale-up effects in process design |

MSZW in Phase Diagram: The MSZW is the region between solubility and supersolubility curves.

Experimental Protocols for MSZW Determination

PAT-Based Methodology Using FTIR and FBRM

Advanced Process Analytical Technology (PAT) tools enable accurate determination of MSZW and solubility. The following protocol utilizes in situ Fourier Transform Infrared (FTIR) spectroscopy and Focused Beam Reflectance Measurement (FBRM):

Materials and Equipment:

- Reactor vessel with temperature control

- In situ FTIR spectrometer with probe

- FBRM probe for particle detection

- Temperature controller and data acquisition system

- Paracetamol in isopropanol (model system) or target API in selected solvent

Procedure:

- Prepare a saturated solution at elevated temperature, ensuring complete dissolution of all solids.

- Implement a controlled cooling ramp (e.g., 0.05 K/min to 0.5 K/min) while monitoring the solution with both PAT tools.

- Use FTIR to track concentration changes by monitoring specific spectral peaks (e.g., 1516 cmâ»Â¹ for paracetamol) [7].

- Simultaneously use FBRM to detect the first appearance of crystals through increased particle counts.

- Record the temperature at which the first crystals appear (cloud point) as the metastable limit.

- The difference between the saturation temperature and this cloud point temperature defines the MSZW for that cooling rate.

- Repeat at different cooling rates to characterize kinetic parameters.

Data Processing:

- Correct FTIR data for temperature effects on absorbance [7].

- Convert IR intensity to concentration using established calibration curves.

- Plot concentration versus temperature to establish solubility curve.

- Correlate FBRM particle count spikes with temperature to identify cloud points.

Polymeric Additive Screening Protocol

This protocol evaluates the effectiveness of polymeric additives in inhibiting nucleation and widening MSZW:

Materials:

- Model compound (e.g., alpha-mangostin for poorly water-soluble drugs) [8]

- Polymer additives (HPMC, PVP, Eudragit, etc.)

- Dissolution media (e.g., 50 mM phosphate buffer pH 7.4)

- Organic solvent for stock solutions (DMSO)

Procedure:

- Prepare polymer solutions at various concentrations (e.g., 500 μg/mL) in dissolution media [8].

- Create supersaturated drug solutions by adding concentrated drug stock solutions to polymer solutions.

- Maintain solutions at constant temperature (e.g., 25°C) with agitation (150 rpm).

- Monitor drug concentration over time using HPLC with regular sampling [8].

- Record induction time (time until first detectable nucleation) for each polymer system.

- Characterize polymer-drug interactions using FT-IR, NMR, and in silico modeling [8].

Troubleshooting Guides and FAQs

Common Experimental Challenges and Solutions

Table: Troubleshooting MSZW Experimental Issues

| Problem | Potential Causes | Solutions |

|---|---|---|

| Irreproducible MSZW measurements | Variable cooling rates; inconsistent solution history; inadequate mixing | Standardize cooling protocol; control thermal history; maintain constant agitation |

| Uncontrolled secondary nucleation | MSZW too narrow; excessive supersaturation; mechanical shock | Widen MSZW with additives; operate at lower supersaturation; avoid vibrations |

| Additives not inhibiting nucleation | Poor polymer-drug interaction; insufficient additive concentration | Screen polymers with complementary functional groups; optimize concentration [8] |

| Inconsistent clear/cloud point detection | PAT sensor fouling; inadequate sensitivity; poor calibration | Implement regular cleaning; validate detection limits; establish robust baselines |

Frequently Asked Questions

Q1: Why does MSZW depend on cooling rate? MSZW is kinetically controlled. Faster cooling rates give less time for nucleation events to occur, resulting in a wider apparent MSZW as the solution can be driven to higher supersaturation before detectable nucleation occurs [6] [7].

Q2: How can I widen the MSZW for my crystallization system? Consider adding polymeric additives that specifically interact with your compound. Effective additives like PVP or HPMC can inhibit nucleation through molecular interactions that increase the energy barrier for nucleation [6] [8]. Chelating agents like EDTA have also proven effective by complexing with impurity ions that might otherwise catalyze nucleation [6].

Q3: What is the relationship between induction time and MSZW? Induction time (tind) is the time required for nucleation to occur at constant supersaturation, while MSZW (ΔTmax) represents the maximum supersaturation achievable under specific cooling conditions before nucleation. Both parameters reflect the nucleation kinetics of the system [8].

Q4: How do I select the right polymer for nucleation inhibition? Selection should be based on specific polymer-drug interactions. Screening should include FT-IR, NMR, and in silico studies to identify polymers that form effective interactions with the drug molecule. PVP often shows effectiveness due to its ability to interact with carbonyl groups through its methyl groups [8].

Q5: Why is my measured MSZW different from literature values? MSZW is highly sensitive to experimental conditions including cooling rate, agitation, solution volume, impurity profile, and detection method. Ensure your experimental parameters match those reported when making comparisons [7].

Nucleation Inhibition Mechanisms and Additive Engineering

Molecular Mechanisms of Nucleation Inhibition

Effective nucleation inhibition additives function through several molecular mechanisms:

Molecular Complexation: Polymers like PVP inhibit crystallization by forming specific interactions with drug molecules, particularly through hydrogen bonding and hydrophobic interactions. NMR studies have demonstrated interactions between PVP's methyl groups and carbonyl groups of drug molecules [8].

Surface Adsorption: Additives adsorb to emerging crystal surfaces, increasing the surface energy required for forming stable nuclei and effectively raising the nucleation barrier.

Impurity Sequestration: Chelating agents like EDTA widen MSZW by complexing with metal ion impurities that might otherwise act as heterogeneous nucleation sites [6].

Solution Structuring: Some polymers alter the solvent structure and diffusion properties, thereby affecting molecular assembly pathways leading to nucleation.

The effectiveness of a polymer depends critically on its specific interactions with the drug molecule rather than general properties like viscosity [8].

Performance Comparison of Common Polymeric Additives

Table: Comparison of Polymer Effectiveness in Nucleation Inhibition

| Polymer | Effectiveness | Mechanism | Application Notes |

|---|---|---|---|

| PVP (Polyvinylpyrrolidone) | High - maintains long-term supersaturation [8] | Specific interaction with drug carbonyl groups via methyl groups [8] | Broad applicability for carbonyl-containing drugs |

| HPMC (Hypromellose) | Variable - drug-dependent effectiveness [8] | Less specific interactions; may not inhibit nucleation effectively for all drugs [8] | Requires case-by-case evaluation |

| Eudragit | Moderate - short-term supersaturation (∼15 min) [8] | Intermediate interaction strength | Suitable for rapid-release formulations |

| HPMCAS | High for specific APIs [9] | Surface adsorption and specific interactions | pH-dependent functionality |

| Water-soluble Chitosan | Effective in pure water systems [8] | Molecular complexation | Limited solubility in buffer media |

Additive Inhibition Mechanisms: Multiple pathways for nucleation inhibition.

The Scientist's Toolkit: Research Reagent Solutions

Essential Materials for MSZW and Nucleation Studies

Table: Key Research Reagents and Equipment

| Item | Function/Application | Examples/Specifications |

|---|---|---|

| PAT Tools | Real-time monitoring of concentration and particle formation | In situ FTIR, FBRM, PVM (Particle View Microscope) [7] |

| Polymer Additives | Nucleation inhibition; MSZW modification | PVP, HPMC, HPMCAS, Eudragit, various cellulosic polymers [8] [9] |

| Chelating Agents | Impurity sequestration; MSZW enhancement | EDTA (effective at ~1 wt%) [6] |

| Crystallization Systems | Automated solubility and MSZW determination | Crystal16, Crystalline, CrystalBreeder [9] |

| Model Compounds | Method development and validation | Paracetamol, Alpha-mangostin, D-mannitol [8] [7] [10] |

| Analytical Instruments | Characterization of polymer-drug interactions | FT-IR, NMR, HPLC, PXRD [8] |

| KRC-00715 | KRC-00715, MF:C25H25F3N8O3, MW:542.5 g/mol | Chemical Reagent |

| Glucoarabin | Glucoarabin, MF:C17H33NO10S3, MW:507.6 g/mol | Chemical Reagent |

Troubleshooting Guide: Two-Step Nucleation Experiments

Issue 1: Inability to Detect Intermediate Liquid Phases

Problem: Researchers cannot consistently observe or detect the transient liquid-like intermediate phases and pre-nucleation clusters that are central to the two-step nucleation model.

Solution: Implement advanced real-time monitoring techniques and optimize solution conditions to stabilize these intermediates for observation.

Step-by-Step Resolution:

- Employ Fluorescence Monitoring: Utilize compounds like BF2DBMb that exhibit mechanofluorochromism. These materials display distinct fluorescence color changes as they transition from monomeric states (purple emission) to amorphous clusters (orange emission) and finally to crystalline states (blue emission) [11].

- Optimize Supersaturation: Carefully control the level of supersaturation. Intermediate amorphous droplets are typically only observable in supersaturated, non-equilibrium states during processes like solvent evaporation [11].

- Use Micro-Droplet Platforms: Implement micro-droplet precipitation systems that serve as miniature reactors. These platforms enable high-throughput statistical analysis of phase transitions under impurity-free conditions, significantly enhancing the detection of liquid-to-dense-liquid phase transitions [12].

Prevention Tips:

- Maintain precise control over solvent composition and evaporation rates

- Use polymer matrices (like PMMA) to partially isolate and "freeze" the molecular assembly process for easier observation [11]

- Implement multiple complementary detection methods (fluorescence, Raman spectroscopy, XRD) for verification [11]

Issue 2: Uncontrolled Crystallization Instead of Amorphous Formation

Problem: Experiments consistently result in direct crystallization through classical one-step nucleation rather than forming the desired amorphous intermediates.

Solution: Modify solvent composition and implement polymer additives that specifically inhibit the crystallization pathway.

Step-by-Step Resolution:

- Adjust Solvent Composition: For carbamazepine systems, vary the methanol/water ratio in the solvent. Higher water content promotes the liquid-to-amorphous-solid transition characteristic of two-step nucleation [12].

- Introduce Specific Polymer Additives: Utilize polymers like polyvinylpyrrolidone (PVP) that effectively inhibit crystal nucleation through specific molecular interactions with the drug compound. PVP has demonstrated superior performance in maintaining supersaturated states compared to HPMC or eudragit [8].

- Control Processing Conditions: Implement rapid solvent evaporation or cooling to promote the kinetic trapping of amorphous states rather than thermodynamically favored crystallization [12].

Prevention Tips:

- Screen multiple polymer additives at different concentrations to identify optimal inhibition conditions

- Characterize drug-polymer interactions early using FT-IR, NMR, and in silico studies [8]

- Avoid heterogeneous nucleation sites by using properly coated microfluidic devices [12]

Issue 3: Poor Physical Stability of Amorphous Phases

Problem: Generated amorphous phases rapidly recrystallize, preventing practical application or further study.

Solution: Develop formulation strategies that enhance amorphous phase stability while maintaining the desired solubility advantages.

Step-by-Step Resolution:

- Formulate Amorphous Solid Dispersions: Incorporate stabilizing polymers that inhibit both nucleation and crystal growth through specific molecular interactions rather than simply increasing solution viscosity [8].

- Create Co-amorphous Systems: Develop multi-component amorphous systems that exhibit improved physical stability through mutual inhibition of crystallization [12].

- Optimize Processing Parameters: In micro-droplet systems, control droplet size and evaporation conditions to influence the size and number of generated amorphous dense liquid clusters, which affects their stability profile [12].

Prevention Tips:

- Select polymers based on their demonstrated ability to inhibit both nucleation and crystal growth, not just one mechanism [8]

- Characterize the molecular mobility of amorphous systems to predict stability

- Consider the balance between solubility enhancement and physical stability during formulation design

Frequently Asked Questions (FAQs)

Q1: What is the fundamental difference between classical and two-step nucleation mechanisms?

A1: Classical nucleation theory assumes a single-step process where molecules add individually to form an embryonic crystal nucleus with the same structure as the bulk crystal. In contrast, the two-step mechanism involves formation of a metastable intermediate phase—typically a dense liquid droplet or amorphous cluster—followed by reorganization into a crystalline structure within this intermediate [13] [14] [11]. This pathway separates density fluctuations from structural ordering fluctuations, often resulting in different kinetic pathways and final crystal properties.

Q2: How do pre-nucleation clusters differ from classical critical nuclei?

A2: Pre-nucleation clusters are stable solute associations that exist before phase separation occurs, lacking a defined interface and not resembling the final crystal structure. They differ fundamentally from classical critical nuclei, which are rare, unstable entities with the same structure as the bulk crystal and defined interfacial tension [13]. Pre-nucleation clusters represent a truly non-classical pathway where organization occurs after aggregation rather than during it.

Q3: Which analytical techniques are most effective for studying two-step nucleation processes?

A3: The most effective approaches include:

- Fluorescence spectroscopy with environmentally sensitive fluorophores to track phase transitions in real-time [11]

- Micro-droplet platforms enabling statistical analysis of numerous individual nucleation events [12]

- Cryogenic transmission electron microscopy (cryoTEM) for direct visualization of early-stage intermediates [12]

- Isothermal titration calorimetry to study the thermodynamics of prenucleation cluster formation [13]

- Combined techniques including FT-IR, NMR, and computational studies to characterize molecular interactions [8]

Q4: How can polymer additives selectively inhibit crystallization in two-step nucleation?

A4: Effective polymers like PVP function through specific molecular interactions with drug molecules rather than general viscosity effects. These interactions include hydrogen bonding, hydrophobic interactions, or specific functional group recognition that preferentially stabilizes amorphous states or disrupts the molecular recognition events necessary for crystal formation [8]. The effectiveness depends on the strength and specificity of these interactions rather than simply increasing solution viscosity.

Q5: What role does solvent composition play in controlling nucleation pathways?

A5: Solvent composition critically influences which nucleation pathway dominates. For carbamazepine, varying methanol/water ratios determines whether the system undergoes direct crystallization or passes through an amorphous intermediate [12]. Solvent properties affect the stability of pre-nucleation clusters, the lifetime of dense liquid intermediates, and the relative kinetic barriers for different pathways, making solvent optimization crucial for controlling nucleation mechanisms.

Table 1: Quantitative Analysis of Carbamazepine Phase Transitions in Micro-Droplet Systems

| Solvent Composition (MeOH/Water) | CBZ Concentration (mg/mL) | Dominant Nucleation Pathway | Intermediate Cluster Size (μm) | Cluster Number per Droplet |

|---|---|---|---|---|

| 100/0 | 1-9 | One-step (liquid-to-crystalline) | Not observed | Not observed |

| 90/10 | 3 | Two-step (liquid-to-amorphous) | 5-15 | 8-15 |

| 70/30 | 3 | Two-step (liquid-to-amorphous) | 10-25 | 12-20 |

Data adapted from carbamazepine micro-droplet experiments [12]

Table 2: Polymer Effectiveness in Nucleation Inhibition for Supersaturated Drugs

| Polymer Additive | Effect on Nucleation Induction Time | Effect on Crystal Growth Rate | Mechanism of Action | Interaction Strength with Drug |

|---|---|---|---|---|

| PVP | Significantly increases | Strongly inhibits | Specific molecular interactions | Strong |

| Eudragit | Moderately increases | Moderately inhibits | Moderate molecular interactions | Moderate |

| HPMC | Minimal effect | Weakly inhibits | Viscosity effects primarily | Weak |

| Water-soluble Chitosan | Increases | Inhibits | Molecular interactions | Compound-dependent |

Data summarized from polymer inhibition studies [8]

Table 3: Fluorescence Characteristics During Two-Step Nucleation of BF2DBMb

| State of Organization | Fluorescence Color | Peak Emission Wavelength (nm) | Observation Conditions |

|---|---|---|---|

| Monomer (dilute solution) | Purple | 413, 430, 460 (shoulder) | Dilute solution |

| Amorphous cluster | Greenish-orange | ~550 | Supersaturated solution |

| Crystal | Blue | 445, 470 | Final crystalline product |

Data from fluorescence monitoring of evaporative crystallization [11]

Detailed Experimental Protocols

Protocol 1: Micro-Droplet Platform for Two-Step Nucleation Studies

Objective: To observe and characterize intermediate phases in two-step nucleation using a micro-droplet precipitation system [12].

Materials:

- Polydimethylsiloxane (PDMS) microfluidic device with 100 μm channel depth

- Carbamazepine solutions in methanol/water mixtures (concentrations: 1-9 mg/mL)

- Continuous phase: Fluorinated oil (FC-40) with 008-fluorosurfactant

- Glass substrates for droplet collection

- Polarized microscope (Nikon Eclipse TE2000-U) with imaging capabilities

Methodology:

- Device Preparation:

- Fabricate microfluidic droplet device using conventional soft lithography

- Treat channel surfaces with aquapel for 10s, followed by nitrogen drying

- Pre-incubate channels with FC-40 oil for 15 minutes prior to experiments

Solution Preparation:

- Prepare saturated carbamazepine solution by adding excess carbamazepine to methanol

- Stir for 1 hour to reach saturation at room temperature

- Prepare solutions with varying methanol/water ratios (100/0, 90/10, 70/10 v/v%)

Droplet Generation and Observation:

- Inject carbamazepine solutions and oil phase into microfluidic device

- Generate monodisperse droplets at flow-focusing junction

- Collect droplets onto glass coverslips pre-coated with 200 μL FC-40

- Immediately transfer to microscope stage for observation

- Record phase transition processes over time

Data Analysis:

- Measure droplet size changes due to solvent evaporation

- Quantify size and number of dense liquid clusters using Image-J software

- Perform statistical analysis on 50-100 droplets for each condition

- Correlate solvent composition with observed nucleation pathway

Protocol 2: Nucleation Induction Time Measurements for Polymer Screening

Objective: To evaluate the effectiveness of polymer additives in inhibiting nucleation in supersaturated drug solutions [8].

Materials:

- Model drug compound (e.g., alpha-mangostin)

- Polymer additives (HPMC, PVP, eudragit)

- Phosphate buffer (50 mM, pH 7.4)

- DMSO for stock solutions

- HPLC system with C18 column

- FT-IR spectrometer

- NMR spectrometer

Methodology:

- Solution Preparation:

- Dissolve polymers in phosphate buffer at concentration of 500 μg/mL

- Prepare stock solution of drug in DMSO (1500 μg/mL)

- Create supersaturated solutions by adding drug stock to polymer solutions (final DMSO concentration: 2% v/v)

Induction Time Measurements:

- Maintain solutions at 25°C with constant stirring at 150 rpm

- Sample at regular time intervals (e.g., 1, 5, 10, 15, 30, 60 minutes)

- Filter immediately through 0.45μm membrane filter

- Dilute filtrate with acetonitrile and analyze by HPLC

- Determine nucleation induction time as point when drug concentration begins to decrease

Interaction Characterization:

- Perform FT-IR spectroscopy on solutions to identify molecular interactions

- Conduct NMR measurements in D2O/DMSO-d6 mixtures

- Perform in silico studies to predict binding interactions

- Measure solution viscosities to separate molecular effects from bulk viscosity effects

Data Interpretation:

- Compare induction times across different polymer systems

- Correlate interaction strength with nucleation inhibition effectiveness

- Rank polymers based on their ability to maintain supersaturation

The Scientist's Toolkit: Research Reagent Solutions

Table 4: Essential Materials for Two-Step Nucleation Research

| Reagent/Material | Function/Application | Key Characteristics | Example Use Cases |

|---|---|---|---|

| Carbamazepine | Model BCS Class II compound | Crystalline drug with multiple polymorphs | Studying solvent effects on nucleation pathway [12] |

| BF2DBMb | Mechanofluorochromic probe | Distinct fluorescence for different aggregation states | Visualizing two-step nucleation in real-time [11] |

| Polyvinylpyrrolidone (PVP) | Polymer nucleation inhibitor | Specific molecular interactions with drugs | Maintaining supersaturation of poorly soluble drugs [8] |

| Microfluidic Droplet Devices | Miniature reaction environments | Enable high-throughput single-event analysis | Statistical analysis of phase transitions [12] |

| HPMC | Polymer additive | Primarily affects solution viscosity | Comparison of inhibition mechanisms [8] |

| Methanol/Water Mixtures | Solvent systems with tunable properties | Variable polarity and solubility parameters | Controlling nucleation pathway selection [12] |

| SIL lipid | SIL lipid, MF:C54H108N4O6, MW:909.5 g/mol | Chemical Reagent | Bench Chemicals |

| EM 1404 | EM 1404, MF:C25H33NO3, MW:395.5 g/mol | Chemical Reagent | Bench Chemicals |

Experimental Workflow and Mechanism Visualization

Diagram 1: Two-Step Nucleation Mechanism

Diagram 2: Experimental Workflow for Nucleation Inhibition Studies

Troubleshooting Guides

Guide 1: Addressing Ineffective Nucleation Inhibition

Problem: Your polymeric additive is not effectively inhibiting nucleation, and crystallization still occurs rapidly in your supersaturated solution.

Solutions:

- Verify Additive-Drug Interaction: The effectiveness of a polymer hinges on its specific molecular interaction with the drug. For instance, Polyvinylpyrrolidone (PVP) can decrease the nucleation rate of a drug like famotidine by orders of magnitude by forming hydrogen bonds and introducing steric hindrance. If no such interaction exists, the polymer will be ineffective. Use FT-IR and NMR to confirm the interaction, as demonstrated in studies with alpha-mangostin [15] [8].

- Optimize Additive Concentration: The inhibitory effect is often concentration-dependent. Systematically investigate the impact of additive concentration using a Design of Experiment (DoE) methodology. For example, the nucleation inhibition effect of PVP on famotidine is dependent on both temperature and concentration [15].

- Check for Confounding Additives: In complex solutions, other components can interfere. In restriction enzyme digestions, for example, contaminants from DNA purification can inhibit the enzyme's activity. Always clean up your substrate prior to critical experiments to remove potential inhibitors [16].

Guide 2: Managing Defect-Induced Unwanted Nucleation

Problem: Surface defects on your substrate or coating are promoting unwanted ice or crystal nucleation, undermining your anti-icing or crystallization control strategy.

Solutions:

- Understand the Defect Mechanism: Surface defects act as nucleation sites by increasing water adsorption energy and local heat transfer rates, which accelerates vapor condensation and ice/crystal nucleation. Even a few defects can significantly raise the heterogeneous ice nucleation temperature [17].

- Implement Self-Healing Materials: To counteract mechanical injuries, use self-healing coatings. A poly(dimethylsiloxane-co-sulfobetaine methacrylate) (PDSB) copolymer can autonomously self-heal at -20°C, restoring its anti-icing performance by repairing defects that would otherwise promote icing [17].

- Mimic Natural Inhibitors: Design your additive to mimic the function of natural antifreeze proteins (AFPs), which feature both ice-binding sites (IBS) and non-ice-binding sites (NIBS) to inhibit nucleation and prevent ice propagation [17].

Guide 3: Controlling Polymorphic Outcome and Crystal Morphology

Problem: The crystalline product is exhibiting an undesired polymorph or unfavorable crystal morphology, affecting stability and performance.

Solutions:

- Leverage Additive-Assisted Crystallization: Utilize additives to direct crystallization toward a specific polymorph. The presence of additives like polymers can be used to achieve a favorable crystal morphology and polymorphism, a key area of research in pharmaceutical development [15].

- Control the Interfacial Energy: The nucleation of a new phase on a substrate is governed by interfacial energy. First-principles calculations, as used in steel research, show that elements like Si can increase the interfacial energy between austenite and cementite (Fe₃C), thereby inhibiting cementite nucleation. Tailoring the interface chemistry is a powerful method for control [18].

- Consider the Nucleation Pathway: For systems like calcium carbonate, small-molecular-weight additives (e.g., citrate, tripolyphosphate) can interact with prenucleation clusters (PNCs), which are precursors to amorphous calcium carbonate (ACC). Additives that integrate into PNCs can be traced into the final ACC and dramatically stabilize it against crystallization [19].

Frequently Asked Questions (FAQs)

FAQ 1: What are the primary molecular mechanisms by which additives inhibit nucleation? Additives employ several key mechanisms to inhibit nucleation. A primary method is specific binding and steric hindrance, where the additive forms targeted interactions (e.g., hydrogen bonds) with the crystallizing molecule or prenucleation cluster, physically blocking their integration into a growing crystal lattice. For example, polymers like PVP inhibit drug nucleation through H-bonding and steric effects [15], while the antifreeze protein DAFP1 binds to and randomizes crystal-forming conformers of D-mannitol in solution [20]. Another mechanism is altering interfacial properties, where an additive adsorbs to a substrate or interface and changes its surface energy, making it less favorable for nucleation, as seen with Si inhibiting cementite formation on austenite [18].

FAQ 2: How does the molecular size of an additive influence its effectiveness? Molecular size dictates the mechanism of action. Small-molecular-weight additives can be extremely potent by integrating directly into the early stages of nucleation. For instance, citrate (CIT) and tripolyphosphate (TPP) can trigger, stabilize, and feed prenucleation clusters (PNCs) in calcium carbonate systems, with their small size allowing them to be incorporated into the resulting amorphous phase and significantly stabilize it [19]. In contrast, polymeric additives often exert their influence through a combination of specific binding sites distributed along a larger chain and the long-range steric hindrance the chain provides, which can disrupt the reorganization of molecules into a critical nucleus [15] [8].

FAQ 3: My additive is incorporated into the solid phase. What does this indicate? Incorporation is a strong indicator that the additive is operating via a co-precipitation or "messy" inhibition mechanism. This is common with highly effective small molecules. In calcium carbonate, additives like TPP and HEDP that are incorporated into the amorphous ACC at significant mass fractions (over 4.5 w %) are the same ones that provide the greatest stabilization against crystallization, raising the crystallization temperature by over 70°C [19]. This deep integration into the solid matrix disrupts its atomic order and mobility, making it much more difficult to reorganize into a crystal.

FAQ 4: Can an additive ever accelerate nucleation instead of inhibiting it? Yes, under specific conditions, additives can promote heterogeneous nucleation. This is a common goal in metal additive manufacturing, where "inoculant" particles are added to the melt to provide surfaces for crystals to nucleate on, controlling the microstructure by promoting the columnar-to-equiaxed transition (CET) [21]. The key is the interfacial energy between the additive particle, the melt, and the solid phase; a low energy barrier promotes nucleation. The same additive can sometimes inhibit nucleation in one system while promoting it in another, depending on the specific interactions.

Quantitative Data on Additive Performance

The following tables summarize experimental data on how various additives alter nucleation kinetics and stability in different systems.

Table 1: Inhibition of Drug Nucleation by Polymers Data from supersaturated drug solutions, showing how polymers increase induction time and suppress nucleation temperature [15] [8].

| Drug / System | Additive | Key Measured Effect | Proposed Inhibition Mechanism |

|---|---|---|---|

| Famotidine (FMT) | Polyvinylpyrrolidone (PVP) | Nucleation rate decreased by orders of magnitude; effect is temperature-dependent. | H-bonding and steric hindrance, as confirmed by molecular modelling. |

| Alpha-Mangostin (AM) | PVP | Effectively maintained long-term supersaturation; best inhibitor among polymers tested. | Interaction between PVP's methyl group and AM's carbonyl group. |

| Alpha-Mangostin (AM) | Hypromellose (HPMC) | No inhibitory effect on AM crystal nucleation was observed. | Lack of effective polymer-drug interaction. |

| p-Aminobenzoic acid | Tailor-Made Additives | Induction times to nucleation reduced by 5 orders of magnitude via IbD method. | Disruption of key intermolecular interactions (synthons) in the crystal. |

Table 2: Stabilization of Amorphous Phases by Small Molecules Data from biomineralization studies, showing how small molecules stabilize amorphous precursors [19].

| Additive | System | Incorporation (w %) | Effect on Crystallization Temp. (Tc) |

|---|---|---|---|

| None (Reference) | Amorphous Calcium Carbonate (ACC) | - | ~340 °C |

| Citrate (CIT) | ACC | 1.3 % | Increased to ~360 °C |

| CPTC | ACC | 3.7 % | Increased to 411 °C |

| HEDP | ACC | 4.5 % | No crystallization observed up to 600 °C |

| Tripolyphosphate (TPP) | ACC | 4.7 % | No crystallization observed up to 600 °C |

Table 3: Inhibition of Ice Nucleation on Functional Coatings Data from anti-icing research, showing the impact of surface defects and their remediation [17].

| Surface Condition | Heterogeneous Ice Nucleation Temp. (TH) | Ice Adhesion Strength | Key Finding |

|---|---|---|---|

| Intact PDMS Coating | -22.6 °C | 38.9 kPa | Baseline performance. |

| PDMS with 3 Defects | -9.5 °C | 105.9 kPa | Defects drastically promote icing and strengthen adhesion. |

| Self-Healing PDSB Coating | < -29.4 °C | < 38.9 kPa | AFP-inspired design inhibits nucleation and reduces adhesion. |

Experimental Protocols

Protocol 1: Measuring Nucleation Induction Time for Drug Solutions

Objective: To determine the time taken for a supersaturated drug solution to nucleate in the presence and absence of a polymeric additive [8].

Materials:

- Model drug (e.g., Alpha-Mangostin)

- Polymer additive (e.g., PVP, HPMC)

- Appropriate buffer (e.g., 50 mM phosphate buffer, pH 7.4)

- DMSO

- HPLC system with UV detector

- Membrane filters (0.45 µm)

Procedure:

- Solution Preparation: Dissolve the polymer in the buffer at the desired concentration (e.g., 500 µg/mL).

- Create Supersaturation: Add a concentrated stock solution of the drug in DMSO to the polymer solution. The final DMSO concentration should be kept low (e.g., 2% v/v) to avoid solvent effects.

- Initiate Experiment: Stir the resulting supersaturated solution at a constant temperature (e.g., 25°C) and agitation speed (e.g., 150 rpm). Consider time "zero" as the moment of mixing.

- Sample and Quantify: At predetermined time intervals, withdraw an aliquot from the solution. Immediately filter it through a 0.45 µm membrane to remove any crystallized material.

- Analyze: Dilute the filtrate appropriately and analyze the drug concentration using HPLC.

- Determine Induction Time: The induction time is the point at which the measured drug concentration in solution begins to drop significantly, indicating the onset of nucleation and crystal growth. Plot concentration vs. time to identify this point.

Protocol 2: Molecular Modelling of Additive-Substrate Interactions

Objective: To use computational methods to predict and understand the molecular-scale interactions between an additive and a crystal surface or prenucleation cluster [15] [22] [18].

Materials:

- High-performance computing workstation

- Molecular modelling software (e.g., for density functional theory (DFT) or grid-based modelling)

Procedure:

- Define the System: Identify the crystal structure of the phase you wish to control. Determine the most relevant crystal face (e.g., through Bravais-Friedel-Donnay-Harker (BFDH) analysis or from literature).

- Build the Model: Construct a computational model of the crystal surface (a "slab" model). Generate a 3D molecular structure of your additive.

- Geometry Optimization: Use DFT (e.g., with GGA-PBE functionals) or other forcefield-based methods to optimize the geometry of both the surface and the additive molecule individually to their lowest energy states.

- Dock the Additive: Place the additive molecule at various positions and orientations on the crystal surface model.

- Calculate Interaction Energy: For each docking configuration, perform a full geometry optimization and calculate the binding or adsorption energy. The formula is typically:

E_ads = E_(total) - (E_(surface) + E_(additive)), where a more negative E_ads indicates a stronger interaction. - Analyze Results: The most stable configuration (most negative E_ads) indicates the preferred binding mode. Analyze the electronic structure (e.g., charge distribution, electron density difference) and intermolecular distances to identify the nature of the interaction (e.g., H-bonding, van der Waals) [18].

Mechanism and Workflow Visualization

Diagram 1: A flowchart illustrating the three primary molecular mechanisms by which additives inhibit the nucleation pathway, preventing a supersaturated solution from forming crystals.

Diagram 2: A workflow diagram outlining the key stages and associated tasks for the systematic development and testing of a nucleation inhibitor, combining computational and experimental approaches.

The Scientist's Toolkit: Research Reagent Solutions

Table 4: Essential Materials for Nucleation Inhibition Research

| Reagent / Material | Function / Application | Example Use Case |

|---|---|---|

| Polyvinylpyrrolidone (PVP) | A polymeric additive that inhibits nucleation via H-bonding and steric hindrance. | Inhibiting nucleation of drugs like famotidine and alpha-mangostin in supersaturated solutions [15] [8]. |

| Antifreeze Proteins (AFPs) / Mimetics | Biological or bio-inspired polymers that bind to ice crystals to inhibit growth and nucleation. | Completely inhibiting the nucleation of D-mannitol; designing self-healing anti-icing coatings [20] [17]. |

| Tripolyphosphate (TPP) | A small-molecular-weight additive that interacts with prenucleation clusters. | Stabilizing amorphous calcium carbonate (ACC) by integrating into its structure, dramatically raising its crystallization temperature [19]. |

| Hypromellose (HPMC) | A cellulose-based polymer used as a crystallization inhibitor. | Often used as a benchmark polymer in pharmaceutical studies; its effectiveness is highly drug-dependent [8]. |

| Design of Experiment (DoE) | A systematic methodology to optimize process parameters and their interactions. | Investigating the combined effect of PVP concentration, temperature, and supersaturation on famotidine nucleation [15]. |

| Differential Scanning Calorimetry (DSC) | A technique to measure thermal transitions, such as the crystallization temperature of an amorphous solid. | Quantifying the stabilization of ACC by additives (e.g., increase in Tc from 340°C to >600°C) [19]. |

| Solid-State NMR (SS-NMR) | Used to characterize the local chemical environment and confirm the incorporation of additives in amorphous solids. | Providing conclusive evidence that TPP is molecularly dispersed within the ACC matrix [19]. |

| Mjn228 | Mjn228, MF:C20H20N4O3, MW:364.4 g/mol | Chemical Reagent |

| DPTIP-prodrug 18 | DPTIP-prodrug 18, MF:C36H44N4O4S, MW:628.8 g/mol | Chemical Reagent |

Technical Support Center: Troubleshooting Guides and FAQs

This section addresses common experimental challenges faced by researchers in the context of nucleation inhibition and additive engineering.

Frequently Asked Questions (FAQs)

Q1: What are the most common reasons for obtaining amorphous precipitate instead of protein crystals? Your experiment is likely operating within the precipitation zone of the phase diagram rather than the nucleation zone. This occurs when the system supersaturation (S) is excessively high, driving the system toward disordered aggregation instead of ordered crystal formation [23]. To correct this, systematically lower the protein or precipitant concentration to shift the conditions into the metastable zone. The incorporation of specific additives, a core principle of additive engineering, can also expand the metastable zone, allowing nucleation to occur at lower, more manageable supersaturation levels [23].

Q2: How can I distinguish protein crystals from salt crystals in my crystallization trial? Distinguishing between protein and salt crystals is a common point of confusion. Relying solely on visible light microscopy can be misleading. Advanced imaging techniques offer more reliable identification [24]:

- Ultraviolet (UV) Imaging: Protein crystals contain aromatic amino acids (like tryptophan) that fluoresce under UV light, while salt crystals do not.

- Second Order Non-linear Imaging of Chiral Crystals (SONICC): This technique is particularly effective for detecting protein microcrystals and those embedded in lipid cubic phases (LCP), as it is specific for non-centrosymmetric structures, a property of protein crystals. Simple observation under a microscope is insufficient for definitive identification.

Q3: Why is crystallizing membrane proteins, like GPCRs, particularly challenging? Membrane proteins present unique difficulties that stem from their native environment [25]:

- Conformational Flexibility and Stability: Their structural flexibility is often exacerbated by the detergents required for extraction and purification, leading to misfolding and instability.

- Complex System Composition: The presence of detergent and endogenous lipids creates a highly complex phase diagram, making condition prediction very difficult.

- Low Success Rate with Standard Methods: Traditional high-throughput screening methods designed for soluble proteins are often ineffective due to the reasons above.

Q4: Our crystallization results are not reproducible. What could be the cause? Poor reproducibility often stems from inconsistencies in the nucleation step, which is inherently stochastic [23]. To improve reproducibility:

- Standardize Protocols: Implement automated liquid handling to eliminate manual pipetting errors and ensure consistent drop volumes [24].

- Control Interfaces: Be aware that air/liquid, liquid/liquid, and solid/liquid interfaces can significantly influence nucleation. Using functionally tailored surfaces or nanoparticles can help control this variable [23].

- Document Precisely: Meticulously record all parameters, including protein batch, temperature, and humidity.

Troubleshooting Common Experimental Issues

Problem: Consistently obtaining no crystals or clear drops.

- Potential Cause: The system conditions reside in the undersaturated or metastable zone without sufficient energy to drive nucleation [23].

- Solutions:

- Increase Supersaturation: Systematically increase the concentration of the precipitant or protein.

- Employ Seeding: Introduce microscopic seeds from a previous crystallization trial to induce growth in the metastable zone.

- Use Heteronucleants: Add functionalized surfaces or nanoparticles that provide a template to lower the energy barrier for nucleation [23].

Problem: Crystals form but are too small for X-ray diffraction ("crystalline shower").

- Potential Cause: The initial nucleation event is too rapid and prolific, depleting the protein solution before large crystals can grow. This is a classic sign of passing too quickly through the optimal nucleation zone [25] [23].

- Solutions:

- Reduce Nucleation Rate: Lower the supersaturation level slightly to discourage excessive nucleation.

- Use Additives: Introduce additives like 3-cyanopyridine (in perovskite research) or other small molecules that decelerate crystallization kinetics, providing a wider processing window for fewer, larger crystals to form [26].

- Optimize Temperature: Perform fine-tuning of incubation temperature.

Problem: Crystals form but are of poor quality (e.g., cracked, multiple phases).

- Potential Cause: Uncontrolled growth conditions or the presence of impurities.

- Solutions:

- Improve Growth Conditions: After nucleation, slowly alter conditions to favor growth over new nucleation (e.g., using dialysis or temperature control).

- Utilize Additive Engineering: Incorporate specific additives that suppress the formation of undesirable polymorphs (e.g., suppressing δ-FAPbI3 in perovskite research) and improve crystal perfection [26].

- Apply External Fields: Studies have shown that applying electric or magnetic fields can improve crystal quality by affecting protein-protein interaction potentials and growth [23].

Quantitative Data and Methodologies

Key Crystallization Parameters and Techniques

Table 1: Comparison of Common Protein Crystallization Techniques [24]

| Technique | Amount of Protein | Suitability for Automation | Key Suitability |

|---|---|---|---|

| Hanging Drop | Small to Large | Possible | Crystallization optimization using high surface tension reagents |

| Sitting Drop | Small | Possible | Initial screening |

| Micro-Batch | Small | Not Possible | For proteins and reagents with minimal interactions with oil |

| Lipid Cubic Phase (LCP) | Small to Large | Possible | For high-quality crystals of membrane proteins |

Table 2: Advanced Imaging Modalities for Crystal Identification [24]

| Imaging Modality | Principle | Key Advantage |

|---|---|---|

| Visible Light | Reflection/refraction in visible spectrum | Suitable for analyzing large crystals |

| Ultraviolet (UV) | Fluorescence from aromatic amino acids | Distinguishes protein crystals from salt |

| Multifluorescence (MFI) | Fluorescence of labelled proteins | Distinguishes crystals of a single protein from a complex |

| SONICC | Second Harmonic Generation | Detects microcrystals and crystals in birefringent media |

Experimental Protocol: Controlled Nucleation via Heterogeneous Surfaces

This protocol outlines a methodology for investigating the impact of functionalized surfaces on protein nucleation, relevant to additive engineering research.

Objective: To determine the effect of surface chemistry on the nucleation rate and crystal quality of a target protein.

Materials:

- Purified target protein solution.

- Crystallization screens (precipitants, buffers, salts).

- Functionalized surfaces (e.g., self-assembled monolayers with different terminal groups, silica nanoparticles).

- Crystallization plates (sitting drop or hanging drop).

- Automated imager or microscope.

Methodology:

- Surface Preparation: Introduce the functionalized surfaces (e.g., chips, nanoparticles) into the crystallization trials. A control without any added surface should always be included.

- Drop Setup: Using an automated drop setter (e.g., NT8 Drop Setter) to ensure reproducibility, mix the protein solution with the precipitant solution in a defined ratio over the functionalized surface and the control well [24].

- Incubation and Monitoring: Seal the plates and incubate at a constant temperature. Use an automated rock imager to periodically capture images of the drops without disturbing them [24].

- Data Collection:

- Nucleation Induction Time: Record the time at which the first crystal appears in each drop [23].

- Nucleation Rate: Count the number of crystals in each drop after a fixed time period.

- Crystal Quality: Assess the final crystal size, morphology, and ultimately, its diffraction resolution.

Analysis: Compare the induction times and crystal counts between the functionalized surfaces and the control. A shorter induction time and/or higher crystal count on a specific surface indicates that it promotes heterogeneous nucleation. The diffraction quality of the resulting crystals is the ultimate metric of success.

Workflow and Pathway Visualization

Protein Crystallization Workflow

Navigating the Crystallization Phase Diagram

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Key Reagents and Materials for Advanced Crystallization

| Reagent / Material | Function in Crystallization | Relevance to Nucleation Inhibition & Additive Engineering |

|---|---|---|

| Functionalized Nanoparticles | Provide a scalable, high-surface-area template for heterogeneous nucleation. | Core research tool for studying and controlling the nucleation interface. Different surface chemistries can either promote or inhibit nucleation [23]. |

| Lipid Cubic Phase (LCP) Materials (e.g., Monoolein) | A matrix that mimics the membrane environment, crucial for crystallizing membrane proteins. | The LCP itself can be seen as an additive that controls nucleation by providing a stabilizing lipidic environment, as successfully used for the β2AR and other GPCRs [25]. |

| Small Molecule Additives (e.g., 3-Cyanopyridine) | Modulate crystallization kinetics and thermodynamics. | Acts as an additive to decelerate crystallization kinetics, suppress undesirable polymorphs, and broaden the processing window, leading to superior crystallinity [26]. |

| Trace Fluorescent Dyes | Enable label-free imaging and distinction of protein crystals from salt. | A diagnostic tool rather than a direct nucleation inhibitor. Allows for high-throughput, automated scoring of crystallization trials, crucial for evaluating the efficacy of other additives [24]. |

| Pkm2-IN-5 | Pkm2-IN-5, MF:C16H15NO3S, MW:301.4 g/mol | Chemical Reagent |

| Leustroducsin C | Leustroducsin C, MF:C34H56NO10P, MW:669.8 g/mol | Chemical Reagent |

Additive Design and Implementation Strategies Across Material Systems

In the context of nucleation inhibition additive engineering research, Deep Docking (DD) has emerged as a transformative computational methodology that enables the rapid screening of ultra-large chemical libraries containing hundreds of millions to billions of compounds. This approach addresses a fundamental challenge in modern drug discovery: the efficient exploration of vast chemical spaces to identify high-affinity inhibitors of pathological aggregation processes. By integrating molecular docking with active learning, DD accelerates virtual screening by 10 to 100-fold compared to traditional brute-force methods, making it feasible to discover potent nucleation inhibitors without requiring supercomputing resources [27] [28].

The relevance of DD to nucleation inhibition is particularly significant for targeting protein misfolding diseases, where the aggregation of proteins like Aβ42 in Alzheimer's disease follows nucleation-dependent kinetics. Secondary nucleation processes, in which existing fibril surfaces catalyze the formation of new toxic aggregates, represent critical intervention points. Deep Docking facilitates the identification of small molecules that bind to these catalytic sites on amyloid fibrils, thereby inhibiting the proliferation of aggregates through structure-based design [27]. This technical support document provides comprehensive guidance for researchers implementing DD workflows, with specific emphasis on applications in nucleation inhibition research.

Core Principles and Mechanism

Deep Docking is an active learning framework that combines traditional physics-based docking with deep neural networks to efficiently screen ultra-large chemical libraries. Instead of docking every compound in a library, the method iteratively trains a model to predict docking scores based on a small subset of actually docked molecules, progressively focusing on the most promising chemical regions [27] [28].

The fundamental advantage of DD lies in its ability to reduce computational requirements by up to 100-fold while maintaining high sensitivity in identifying true binders. In practice, researchers have screened libraries of over 539 million compounds to discover inhibitors of Aβ42 aggregation with a remarkable 54% experimental hit rate, demonstrating the method's exceptional efficiency and predictive power for nucleation inhibition targets [27].

Workflow Visualization

The following diagram illustrates the iterative Deep Docking workflow for screening ultra-large chemical libraries:

Technical FAQs & Troubleshooting Guides

Implementation Challenges

FAQ 1: What are the common failure points in Deep Docking pipelines, and how can they be diagnosed?

Deep Docking pipelines can fail due to several technical issues, with the most common being poor neural network training, inadequate sampling in early iterations, and inaccurate pose prediction. Diagnosis should begin with monitoring the enrichment of known active compounds throughout iterations. If active compounds are not being enriched, the issue likely lies in the initial docking accuracy or training set diversity. For nucleation inhibition targets specifically, ensure your training set includes compounds with known secondary nucleation inhibition activity to maintain relevant chemical diversity [27] [29].

Troubleshooting Guide:

- Symptom: Consistently poor hit rates across iterations.

- Potential Cause: Inadequate initial sampling or biased training set.

- Solution: Increase the initial random sample size to 5-10% of the library and incorporate known nucleation inhibitors as positive controls in the training set.

- Verification: Check the docking pose accuracy against experimentally validated complexes for your target using RMSD calculations [29].

FAQ 2: How does Deep Docking performance vary between different target classes, particularly for challenging nucleation inhibition targets?

Performance varies significantly based on target characteristics. For well-defined binding pockets (e.g., enzyme active sites), traditional docking shows robust performance, while Deep Docking provides efficiency gains. For challenging protein-protein interaction interfaces and shallow binding surfaces common in nucleation inhibition targets (e.g., fibril surfaces for secondary nucleation), both traditional and Deep Docking face accuracy challenges. In these cases, the Deep Docking model's performance becomes highly dependent on the underlying docking method's capability to identify correct poses for such targets [28].

Troubleshooting Guide:

- Symptom: Poor pose prediction accuracy for nucleation-related targets.

- Potential Cause: Inadequate handling of flexible binding surfaces or solvation effects.

- Solution: Implement consensus scoring with multiple docking programs, incorporate explicit water molecules in critical positions, and use molecular dynamics refinement for top hits.

- Verification: Compare predicted binding poses with experimental structures (e.g., from cryo-EM) when available [29].

Performance Optimization

FAQ 3: What computational resources are required for screening ultra-large libraries, and how can workflow efficiency be optimized?

Screening billion-compound libraries requires significant but not prohibitive resources. A typical DD run screening 500 million compounds requires approximately 1-2 weeks on a medium-sized computing cluster (100-200 cores). The key efficiency advantage comes from docking only 1-5% of the total library while maintaining high hit recovery rates [27] [28].

Optimization Strategies:

- Hardware Utilization: Leverage GPU-accelerated docking (Vina-GPU) for 5-10x speed improvement in the docking phase [27].

- Library Preparation: Pre-filter libraries using drug-likeness rules (Lipinski's Rule of Five, Veber criteria) and chemical diversity metrics to remove non-viable compounds early [30].

- Parallelization: Implement the DD pipeline across multiple computing nodes, with special attention to parallelizing the neural network inference phase [31].

FAQ 4: How can researchers validate Deep Docking results before committing to experimental testing?

Validation should occur at multiple levels: methodological, computational, and limited experimental. For methodological validation, implement retrospective screening benchmarks with known actives and decoys to calculate enrichment factors. For computational validation, use molecular dynamics simulations to assess binding stability of top hits. For early experimental validation, employ tiered biochemical assays starting with high-throughput aggregation inhibition assays [27] [29].

Validation Protocol:

- Retrospective Screening: Calculate enrichment factors (EF) using known nucleation inhibitors as true positives spiked into a decoy library. Target EF1% > 20 for a successful run [28].

- Pose Stability: Run short (50-100 ns) molecular dynamics simulations to verify binding mode stability and calculate binding free energies (MM-PBSA/GBSA) [29].

- Experimental Triaging: Implement kinetic aggregation assays (ThT fluorescence) for initial experimental confirmation before proceeding to more complex cellular models [27].

Experimental Protocols & Methodologies

Standard Deep Docking Implementation

Protocol 1: Open-Source Deep Docking Pipeline for Nucleation Inhibition Targets

This protocol adapts the open-source Deep Docking pipeline for discovering secondary nucleation inhibitors of Aβ42 aggregation [27].

Materials and Software Requirements:

- Chemical Libraries: ZINC20, Enamine REAL, or custom ultra-large libraries (500M+ compounds)

- Docking Software: AutoDock Vina or Vina-GPU (open-source)

- Ligand Preparation: RDKit for 3D conformation generation

- Computing Resources: 100+ CPU cores or GPU acceleration recommended

Step-by-Step Procedure:

- Target Preparation: Obtain 3D structure of target (e.g., Aβ42 fibril PDB ID: 5OQV). Prepare protein by adding hydrogens, assigning charges, and defining binding site.

- Library Pre-processing: Filter library using Rule of Five and Veber criteria. For nucleation inhibition, include chemical diversity to cover potential fibril surface binders.

- Initial Sampling: Randomly select 1-5 million compounds (0.1-1% of ultra-large library) as initial training set.

- Ligand Preparation: Generate 3D conformations using RDKit energy minimization or download pre-computed conformations from ZINC20.

- Docking Phase: Dock training set compounds against target using Vina-GPU with standardized parameters (exhaustiveness = 32, energy_range = 5).

- Model Training: Train deep neural network (3-5 hidden layers, 1000-2000 neurons each) to predict docking scores from molecular fingerprints.

- Iterative Phase: For 4-5 iterations:

- Use trained model to predict docking scores for entire library

- Select top 1-2 million predicted hits

- Add random sample (10%) to maintain diversity

- Dock enriched subset

- Retrain neural network on new data

- Final Selection: After final iteration, select top 100-500 ranked compounds for experimental validation.

Validation Metrics:

- Computational: Monitor enrichment of known actives throughout iterations

- Experimental: Validate using kinetic aggregation assays (ThT fluorescence) and surface plasmon resonance for binding affinity [27]

Specialized Protocol for Nucleation Inhibition

Protocol 2: Targeting Secondary Nucleation Sites on Amyloid Fibrils

This specialized protocol focuses on identifying inhibitors that specifically target catalytic surfaces on amyloid fibrils to prevent secondary nucleation [27].

Materials:

- Target Structure: Fibril structure with identified secondary nucleation sites (e.g., Aβ42 fibril)

- Control Compounds: Known nucleation inhibitors (e.g., adapranelm) as positive controls

- Specialized Assays: Kinetic aggregation assays, surface plasmon resonance

Procedure Modifications:

- Binding Site Definition: Define grid box to encompass known secondary nucleation sites on fibril surface, confirmed by mutagenesis studies.

- Training Set Enrichment: Include known fibril-binding compounds in initial training set to bias model toward relevant chemotypes.

- Consensus Scoring: Implement consensus docking scores from multiple programs (Vina, RosettaVS) to improve prediction accuracy for challenging fibril surfaces.

- Pharmacophore Filtering: Apply pharmacophore constraints based on known nucleation inhibitor features (e.g., aromatic groups, hydrogen bond donors/acceptors).

- Experimental Validation Priority:

- Primary Screening: Kinetic aggregation assays to measure inhibition potency (IC50)

- Secondary Confirmation: Surface plasmon resonance to verify fibril binding affinity (KD)

- Mechanistic Studies: Neuronal culture models to assess reduction in aggregate toxicity [27]

Performance Benchmarking & Data Analysis

Quantitative Performance Metrics

Table 1: Deep Docking Performance Across Various Targets

| Target Category | Library Size | Compounds Docked | Hit Rate | Potency Range | Reference |

|---|---|---|---|---|---|

| Aβ42 Fibrils (Secondary Nucleation) | 539 million | 35 | 54% | Low nanomolar KD | [27] |

| STAT3 SH2 Domain | 5.51 billion | ~120,000 | 50.0% | Single-digit µM | [28] |

| STAT5b SH2 Domain | 5.59 million | ~120,000 | 42.9% | Single-digit µM | [28] |

| KLHDC2 | Multi-billion | N/A | 14% | Single-digit µM | [31] |

| NaV1.7 | Multi-billion | N/A | 44% | Single-digit µM | [31] |

Table 2: Comparison of Docking Methods for Nucleation Inhibition Applications

| Method | Pose Accuracy (RMSD ≤ 2Å) | Physical Validity (PB-valid) | Virtual Screening Enrichment | Computational Speed | Best Use Case |

|---|---|---|---|---|---|

| Traditional (Glide SP) | 70-80% | >94% | High | Slow | Final validation, high-accuracy poses |

| Deep Docking | Comparable to traditional | Dependent on base method | Very High | Very Fast | Ultra-large library screening |

| Generative Diffusion | >75% | 40-63% | Moderate | Fast | Pose prediction for novel chemotypes |

| Regression-based | 30-60% | 20-50% | Low | Very Fast | Initial triaging only |

| Hybrid Methods | 70-75% | 70-80% | High | Moderate | Balanced accuracy/speed needs |

Data Interpretation Guidelines

When analyzing Deep Docking results for nucleation inhibition applications:

Hit Validation: Prioritize compounds that show consistent ranking across multiple docking programs and iterations. For nucleation inhibitors, specifically look for compounds predicted to bind at fibril surfaces involved in secondary nucleation processes [27].

Potency Correlations: While docking scores provide relative rankings, they may not directly correlate with experimental potency. Use consensus scoring and binding free energy calculations for improved correlation with experimental KD values [29].

Chemical Diversity: Ensure final hit lists maintain chemical diversity to avoid oversampling specific chemotypes. Include diversity picking (MaxMin algorithm) in the final selection process [28].

Research Reagent Solutions

Table 3: Essential Computational Tools for Deep Docking Implementation

| Tool Name | Function | Key Features | Application in Nucleation Inhibition |

|---|---|---|---|

| AutoDock Vina/Vina-GPU | Molecular Docking | Open-source, GPU acceleration | Base docking method for DD pipeline |

| RDKit | Cheminformatics | Molecular descriptor calculation, 3D conformation generation | Ligand preparation and fingerprint generation |

| ZINC20 Database | Compound Library | 1+ billion commercially available compounds | Source of screening compounds |

| Enamine REAL Database | Compound Library | 5+ billion make-on-demand compounds | Ultra-large library source |

| RosettaVS | Docking & Scoring | High-precision docking, flexible backbone | Validation docking for top hits |

| Boltz-2 | AI Co-folding | Multimodal structure & affinity prediction | Pose generation and affinity estimation [32] |

Workflow Integration Diagram

The following diagram illustrates how Deep Docking integrates with experimental validation in nucleation inhibition research:

Technical Support Center

Troubleshooting Guides

Guide 1: Addressing Inconsistent Nucleation Inhibition Results

Problem: The induction time for drug nucleation is shorter than expected, or results vary significantly between experiments.