Kinetic Stabilization in Inorganic Synthesis: Principles, Strategies, and Biomedical Applications

This article provides a comprehensive exploration of kinetic stabilization, a fundamental concept governing the formation and longevity of metastable inorganic and biomolecular structures. Tailored for researchers, scientists, and drug development professionals, it bridges theoretical foundations with practical applications. The scope spans from the core principles differentiating kinetic and thermodynamic control to advanced methodological strategies for stabilizing proteins, biotherapeutics, and inorganic catalysts. It further delves into troubleshooting aggregation and instability issues, optimizing synthesis conditions, and validating stability through modern kinetic modeling and analytical techniques. The content synthesizes recent scientific advances to offer a actionable guide for leveraging kinetic control to develop more effective and stable biomedical products, from complex biologics to innovative drug delivery systems.

Kinetic Stabilization in Inorganic Synthesis: Principles, Strategies, and Biomedical Applications

Abstract

This article provides a comprehensive exploration of kinetic stabilization, a fundamental concept governing the formation and longevity of metastable inorganic and biomolecular structures. Tailored for researchers, scientists, and drug development professionals, it bridges theoretical foundations with practical applications. The scope spans from the core principles differentiating kinetic and thermodynamic control to advanced methodological strategies for stabilizing proteins, biotherapeutics, and inorganic catalysts. It further delves into troubleshooting aggregation and instability issues, optimizing synthesis conditions, and validating stability through modern kinetic modeling and analytical techniques. The content synthesizes recent scientific advances to offer a actionable guide for leveraging kinetic control to develop more effective and stable biomedical products, from complex biologics to innovative drug delivery systems.

Kinetic vs. Thermodynamic Control: Mastering the Fundamentals of Reaction Pathways

Defining Kinetic and Thermodynamic Stability in Chemical Systems

The concepts of kinetic and thermodynamic stability are foundational to predicting and controlling chemical behavior across scientific disciplines, from drug development to inorganic materials synthesis. Thermodynamic stability describes the inherent stability of a chemical state defined by its global free energy minimum, while kinetic stability describes how long a system remains in a given state, determined by the energy barriers between states [1]. Within the context of inorganic synthesis research, a material may be thermodynamically stable yet unsynthesizable due to insurmountable kinetic barriers, or conversely, a kinetically stabilized metastable phase may be isolated despite not being the thermodynamic ground state [2]. This whitepaper provides an in-depth technical guide to these principles, detailing their definitions, quantitative relationships, and critical implications for research and development.

Core Principles and Energetic Landscapes

Fundamental Definitions

Thermodynamic Stability is a measure of the inherent stability of a chemical system relative to its possible products or alternative states, based on the overall change in free energy (ΔG). A thermodynamically stable system exists in a state (e.g., a local or global free energy minimum) that has a lower free energy than all other possible states or transformation products. A system is considered thermodynamically unstable if a lower-free-energy state exists, making the transformation to that state spontaneous from a purely thermodynamic perspective [1] [3].

Kinetic Stability is a measure of the persistence of a system in its current state over time, dictated by the magnitude of the activation energy (Ea or ΔG≠) for a transformation pathway. A kinetically stable system may be thermodynamically unstable but persists because the rate of its transformation is negligibly slow on a relevant timescale. This high kinetic stability, or "kinetic trapping," arises from a significant energy barrier that prevents the system from reaching a more stable state [1] [3].

The Potential Energy Surface

The relationship between kinetic and thermodynamic stability is best visualized on a potential energy surface. For chemical systems, this is typically represented by a thermodynamic potential like Gibbs Free Energy (G) under constant temperature and pressure [1].

Table 1: Key Features of a Potential Energy Surface

| Feature | Symbolic Representation | Mathematical Condition | Description |

|---|---|---|---|

| Local Minimum | N, I | $$\frac{\mathrm{d}G}{\mathrm{d}x} = 0$$, $$\frac{\mathrm{d^2}G}{\mathrm{d}x^2} > 0$$ | A metastable state (kinetically stable). |

| Global Minimum | F | $$\frac{\mathrm{d}G}{\mathrm{d}x} = 0$$, $$\frac{\mathrm{d^2}G}{\mathrm{d}x^2} > 0$$ | The thermodynamically stable state. |

| Transition State | TS, ‡ | $$\frac{\mathrm{d}G}{\mathrm{d}x} = 0$$, $$\frac{\mathrm{d^2}G}{\mathrm{d}x^2} < 0$$ | The highest-energy point on the reaction path. |

| Activation Energy | Ea, ΔG≠| The energy difference between reactant and transition state. | |

| Free Energy Change | ΔG | The energy difference between reactant and product. |

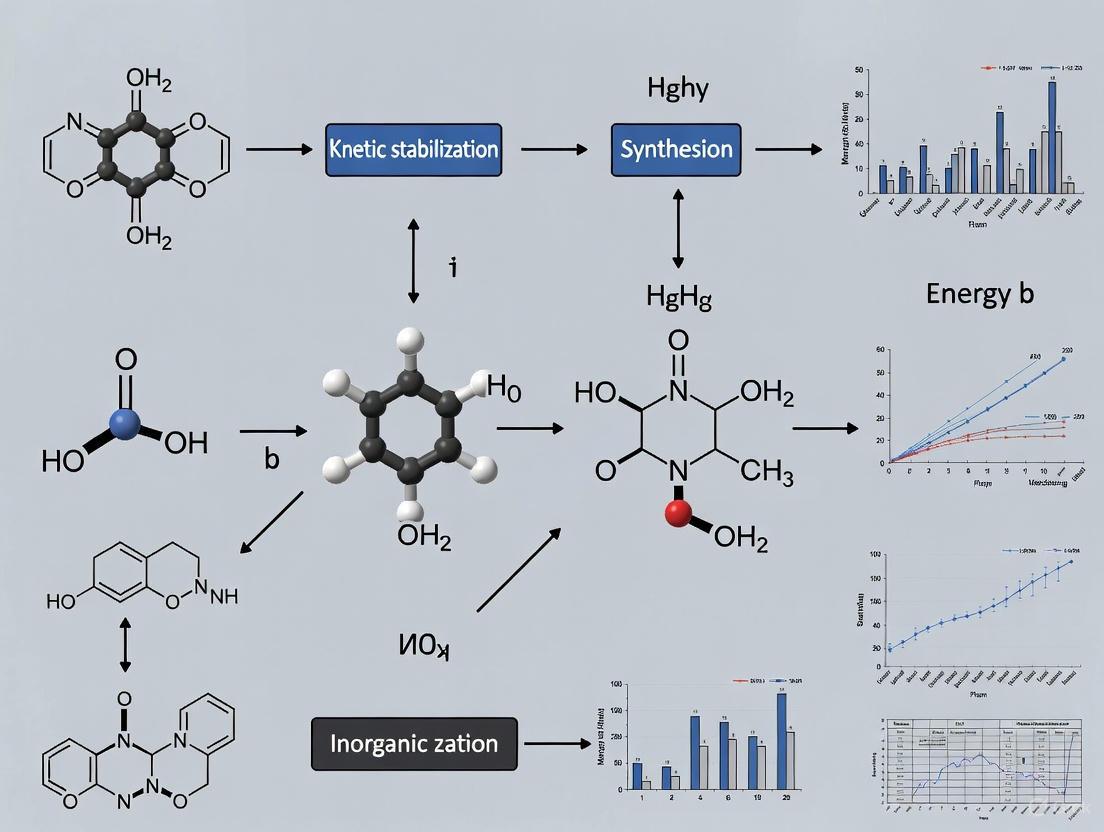

The following diagram illustrates a generalized energy landscape for a system where the kinetic and thermodynamic products differ.

In this landscape, the kinetic product forms faster because the reaction pathway to its state has a lower activation energy (Eaâ‚). However, this product is metastable. The thermodynamic product is more stable (lower in free energy) but forms more slowly due to a higher activation energy (Eaâ‚‚) from the kinetic product, or potentially a high activation energy directly from the reactant [4] [1].

Quantitative Relationships and Key Metrics

The rates of reactions and the stability of states are quantitatively described by key equations.

Table 2: Quantitative Descriptors of Stability

| Concept | Governing Equation | Key Parameters & Interpretation |

|---|---|---|

| Thermodynamic Control | ΔG = -RT·ln(K) | K: Equilibrium constant. ΔG: Negative value indicates a spontaneous process. |

| Kinetic Control (Arrhenius Eq.) | k = A·exp(-Ea/RT) | k: Reaction rate constant. Ea: Activation energy. High Ea leads to low k and high kinetic stability. |

| Kinetic Control (Eyring Eq.) | k = (k₀)·exp(-ΔG≠/RT) | ΔG≠: Activation free energy. k₀: Pre-exponential factor. |

The balance between these controls determines the observable outcome of a reaction. Under conditions of kinetic control (shorter reaction times, lower temperatures), the product distribution is determined by the relative rates of formation (ΔG≠). Under thermodynamic control (longer reaction times, higher temperatures), the system reaches equilibrium, and the product distribution is determined by their relative stabilities (ΔG) [4] [1].

Experimental Protocols for Stability Assessment

Determining Kinetic Parameters for Enzyme Inhibition

Characterizing mechanism-based enzyme inhibition (MBI) is critical in drug development, as it inactivates metabolic enzymes. A Mechanistically-based Experimental Protocol (MEP) has been developed to accurately determine kinetic parameters like the maximum inactivation rate constant (kᵢₙâ‚câ‚œ) and the inactivator concentration for half-maximal inactivation (K_I) [5].

Table 3: Research Reagent Solutions for MEP Analysis

| Reagent / Component | Function in the Protocol |

|---|---|

| Mechanism-Based Inactivator (MBEI) | The compound under investigation that causes time-dependent enzyme inactivation. |

| Probe Substrate | A known substrate for the enzyme used to measure remaining enzymatic activity. |

| Enzyme Preparation | The purified target enzyme (e.g., cytochrome P450). |

| Cofactor System | e.g., NADPH for P450 enzymes, required for catalytic activity. |

| Nonlinear Optimization Software | Used to fit experimental data to a kinetic model for parameter estimation. |

The experimental workflow involves three concurrent parts to deconvolute the complex kinetics of metabolism, reversible inhibition, and time-dependent inactivation.

This MEP protocol recovers more accurate and precise estimates of kinetic parameters compared to conventional protocols, improving the quantitative assessment of a drug's in vivo interactions [5].

Predicting Protein Aggregation Stability

For biologics development, predicting the long-term stability of proteins, such as the formation of aggregates, is essential for determining shelf life. A first-order kinetic model combined with the Arrhenius equation enables accurate predictions based on short-term accelerated stability data [6].

The general workflow involves:

- Quiescent Storage Stability Study: Protein drug substances are stored at multiple temperatures (e.g., 5°C, 25°C, 40°C) for several months.

- Periodic Sampling and Analysis: At defined intervals, samples are analyzed using techniques like Size Exclusion Chromatography (SEC) to quantify the level of high-molecular-weight aggregates.

- Model Fitting: The aggregate formation data at each temperature is fitted to a first-order kinetic model to determine the reaction rate constant (k) at each temperature.

- Arrhenius Plotting: The natural logarithm of the rate constants (ln k) is plotted against the reciprocal of absolute temperature (1/T). The linear fit to this data allows for the extrapolation of the degradation rate (k) at the desired storage temperature (e.g., 5°C).

- Shelf-Life Prediction: The extrapolated rate constant is used to predict the time required for aggregates to reach a critical threshold, thereby defining the product's shelf life [6].

This approach, part of an Accelerated Predictive Stability (APS) framework, provides more precise stability estimates than linear regression and is gaining regulatory acceptance [6].

Application in Inorganic Synthesis and Material Discovery

The principles of kinetic and thermodynamic stabilization are central to the challenge of predicting synthesizable inorganic crystalline materials. Traditional proxies for synthesizability, such as charge-balancing or thermodynamic stability calculated from density-functional theory (DFT), have significant limitations. DFT, for instance, fails to account for kinetic stabilization and captures only about 50% of known synthesized materials [2].

Machine learning models like SynthNN have been developed to address this gap. SynthNN is a deep-learning classification model that predicts the synthesizability of inorganic chemical formulas by learning directly from the entire distribution of previously synthesized materials in databases like the Inorganic Crystal Structure Database (ICSD) [2].

- Learning Chemical Intuition: Without explicit programming of chemical rules, SynthNN learns principles like charge-balancing, chemical family relationships, and ionicity from the data itself [2].

- Performance: In benchmarking, SynthNN identifies synthesizable materials with 7x higher precision than charge-balancing and 1.5x higher precision than the best human expert, completing the task orders of magnitude faster [2].

- Role in a Research Workflow: SynthNN acts as a synthesizability constraint within a broader materials discovery pipeline. After a large space of candidate materials is generated computationally, SynthNN filters for those most likely to be synthetically accessible, guiding experimental efforts toward feasible targets and increasing the success rate of discovery campaigns [2].

Kinetic and thermodynamic stability are distinct yet interconnected concepts that govern the behavior and viability of chemical systems. Thermodynamic stability indicates the ultimate resting state of a system, while kinetic stability determines its practical lifetime and functionality. The mastery of this distinction is not merely academic; it is a critical tool for modern research. It enables the rational design of long-lived protein therapeutics, the accurate prediction of drug metabolism interactions, and the efficient discovery of novel, synthesizable inorganic materials. As computational methods like SynthNN demonstrate, integrating both kinetic and thermodynamic considerations into research workflows is essential for bridging the gap between theoretical prediction and experimental realization, thereby accelerating innovation across chemistry and materials science.

In chemical synthesis, particularly within inorganic and drug development research, the final composition of a product mixture is often not a simple function of which product is most stable. Instead, it is determined by the competition between the rate of product formation (kinetics) and the relative stability of the products (thermodynamics). This competition gives rise to the concepts of kinetic and thermodynamic control, a fundamental principle that dictates reaction outcomes in complex molecular systems. The pathway a reaction follows is profoundly influenced by the reaction conditions, such as temperature, pressure, and solvent, which can steer the reaction towards one product or another [7] [8].

When a single reactant can transform into multiple different products via competing pathways, the reaction landscape is defined by two key factors:

- Kinetic Control favors the product that forms the fastest. This is typically the product with the lowest activation energy (Ea) barrier for its formation. Under kinetic control, the product ratio is determined by the relative rates of the competing reactions [7] [8].

- Thermodynamic Control favors the most stable product. This is the product with the lowest Gibbs free energy (G). Under thermodynamic control, the product ratio is determined by the relative stabilities of the products, as the reaction is allowed to reach equilibrium [7] [8].

A reaction is said to be under kinetic control when the product-forming steps are irreversible, or when the reaction is halted before the products can interconvert and reach equilibrium. Conversely, thermodynamic control takes over when the reaction is reversible and sufficient time is allowed for the system to establish equilibrium [7]. The product that forms faster is called the kinetic product, while the more stable product is called the thermodynamic product [7] [9].

Table 1: Core Characteristics of Kinetic and Thermodynamic Control

| Feature | Kinetic Control | Thermodynamic Control |

|---|---|---|

| Governing Factor | Reaction rate (kinetics) | Product stability (thermodynamics) |

| Product Favored | Kinetic product (forms faster) | Thermodynamic product (more stable) |

| Key Determining Parameter | Activation energy (Ea) | Gibbs free energy (ΔG°) |

| Typical Reaction Conditions | Lower temperatures, shorter reaction times, irreversible conditions | Higher temperatures, longer reaction times, reversible conditions |

| Dependence on Reaction Time | Product ratio is time-dependent; the first product formed is the kinetic product. | Product ratio is time-independent at equilibrium. |

| Mathematical Relationship | ln([A]t/[B]t) = ln(kA/kB) = -ΔEa/RT |

ln([A]∞/[B]∞) = ln Keq = -ΔG°/RT |

Fundamental Principles and Energetics

The underlying principles of kinetic and thermodynamic control can be visualized on a reaction coordinate diagram. In such a diagram, the kinetic product is associated with the transition state that has the lower activation energy, while the thermodynamic product is associated with the global energy minimum on the product side.

The Role of the Activation Energy Barrier: The activation energy (Ea) is the minimum energy required for reactants to transform into products. A reaction pathway with a lower Ea will proceed at a faster rate at a given temperature. Consequently, when a reactant has two possible pathways leading to different products, the pathway with the lower Ea will be favored initially, leading to the kinetic product. This is true even if this product is higher in energy (less stable) than an alternative product [8].

The Role of Product Stability (Gibbs Free Energy): The thermodynamic stability of a product is quantified by its Gibbs free energy. The product with the lowest free energy is the most stable and is favored at equilibrium. For the system to achieve this equilibrium, there must be a pathway—either through reversibility of the product-forming step or through a separate mechanism—that allows the less stable kinetic product to convert back to intermediates and then form the more stable thermodynamic product [7].

Table 2: Quantitative Parameters Governing Reaction Control

| Parameter | Symbol | Role in Kinetic Control | Role in Thermodynamic Control |

|---|---|---|---|

| Activation Energy | Ea, ΔG‡ | Lower Ea for the kinetic product pathway dictates faster formation. | Not a direct factor once equilibrium is established. |

| Gibbs Free Energy | ΔG° | The kinetic product has a higher free energy (less stable). | Lower ΔG° for the thermodynamic product dictates greater stability at equilibrium. |

| Equilibrium Constant | Keq | The product ratio does not reflect the equilibrium constant. | The product ratio is determined by Keq. |

| Temperature | T | Lower temperatures enhance kinetic selectivity by slowing equilibration. | Higher temperatures often speed up the attainment of equilibrium. |

| Reaction Rate Constant | k | The ratio of rate constants (kkinetic/kthermo) determines the initial product ratio. | Rate constants for forward and reverse reactions determine the position of equilibrium. |

Diagram 1: Generalized reaction coordinate diagram for competing pathways. TS Kin is the transition state for the kinetic pathway, and TS Thermo for the thermodynamic pathway. The kinetic product forms faster due to a lower Ea, but the thermodynamic product is more stable.

Exemplary Chemical Systems and Experimental Protocols

The principles of kinetic and thermodynamic control manifest across various chemical domains, from organic to inorganic synthesis. Below are detailed experimental protocols for key model systems that clearly demonstrate this phenomenon.

Protocol 1: Diels-Alder Reaction of Cyclopentadiene and Furan

This classic cycloaddition reaction produces two isomeric adducts, with the dominant product switching based on temperature and reaction time, providing a clear illustration of kinetic versus thermodynamic control [7].

- Objective: To demonstrate the temperature-dependent product ratio between the endo (kinetic) and exo (thermodynamic) adducts.

- Materials:

- Diene: Freshly cracked cyclopentadiene

- Dienophile: Furan

- Solvent: Benzene or dichloromethane (DCM)

- Equipment: Schlenk flask, condenser, heating mantle, ice bath, equipment for NMR spectroscopy or GC-MS analysis.

- Methodology:

- Prepare a 0.1 M solution of cyclopentadiene and a 0.1 M solution of furan in an inert solvent (e.g., benzene).

- For Kinetic Control (Low Temperature): Mix the two solutions in a sealed vessel and maintain at room temperature (approx. 25 °C) for a short period (e.g., 1-2 hours). Monitor the reaction by TLC.

- For Thermodynamic Control (Elevated Temperature): Mix the two solutions in a flask fitted with a reflux condenser. Heat the mixture to 81 °C and reflux for an extended period (e.g., 24-48 hours) [7].

- Work-up and Analysis: After the allotted time, cool the reaction mixture and concentrate under reduced pressure. Analyze the crude product mixture using ( ^1H )-NMR spectroscopy or GC-MS. The endo isomer (kinetic product) will be the major product from the room-temperature reaction, while the exo isomer (thermodynamic product) will dominate the high-temperature reaction mixture.

- Key Observations: The exo product is thermodynamically more stable due to reduced steric congestion. However, the endo product is favored kinetically due to stabilizing secondary orbital interactions in the transition state, leading to a lower activation energy for its formation [7].

Protocol 2: Deprotonation of an Unsymmetrical Ketone

The formation of enolates from unsymmetrical ketones is a cornerstone reaction in synthetic chemistry, and the choice of enolate is a direct application of kinetic versus thermodynamic control [7].

- Objective: To selectively form either the kinetic or thermodynamic enolate from 2-methylcyclohexanone.

- Materials:

- Substrate: 2-methylcyclohexanone

- Kinetic Base: Lithium diisopropylamide (LDA) in tetrahydrofuran (THF)

- Thermodynamic Base: Sodium hydride (NaH) or potassium hydride (KH) in THF

- Electrophile: A trapping agent like iodomethane (CH₃I)

- Equipment: Round-bottom flask, syringe pump, N₂ or Ar atmosphere, dry ice/acetone bath (-78 °C).

- Methodology:

- For Kinetic Enolate Control:

- Under an inert atmosphere, cool a solution of 2-methylcyclohexanone in dry THF to -78 °C.

- Slowly add a 1.0 M solution of LDA in THF via syringe pump. LDA is a strong, sterically hindered base that removes a proton irreversibly.

- The most accessible, least substituted α-proton is removed fastest, yielding the kinetic enolate (less substituted).

- After 30 minutes, add iodomethane to trap the enolate as the methylated product. Analyze the regiochemistry of the product via NMR.

- For Thermodynamic Enolate Control:

- Under an inert atmosphere, add a solution of 2-methylcyclohexanone in dry THF to a suspension of NaH in THF at 0 °C to room temperature.

- NaH is a strong but less hindered base, allowing for equilibration of the initially formed enolates via reversible proton transfer.

- The reaction will equilibrate to favor the more highly substituted, stable enolate (thermodynamic enolate).

- After 1-2 hours, add iodomethane to trap the equilibrated enolate mixture. Analysis will show a predominance of the product derived from the more substituted enolate.

- For Kinetic Enolate Control:

- Key Observations: The kinetic enolate forms faster due to the lower steric hindrance involved in deprotonating the less substituted alpha carbon. The thermodynamic enolate is more stable because the negative charge and double bond are more highly substituted [7].

Protocol 3: Electrophilic Addition to 1,3-Butadiene

The addition of hydrogen bromide (HBr) to 1,3-butadiene results in both 1,2- and 1,4-addition products, with the ratio controlled by temperature [7] [9].

- Objective: To show temperature-dependent selectivity between 1,2- (kinetic) and 1,4- (thermodynamic) addition products.

- Materials:

- Diene: 1,3-Butadiene gas (or a solution in an inert solvent) or a conjugated diene like trans-1,3-pentadiene.

- Electrophile: Anhydrous hydrogen bromide (HBr) gas.

- Solvents: Inert organic solvent (e.g., pentane, DCM).

- Equipment: Gas-tight syringe, cold bath, warm water bath, GC-MS for analysis.

- Methodology:

- For Kinetic Control (1,2-adduct): Bubble HBr gas slowly into a solution of 1,3-butadiene maintained at a low temperature (e.g., -80 °C to 0 °C). Quench the reaction after a short time. Analysis (e.g., GC-MS) will show a high proportion of 3-bromo-1-butene (1,2-adduct).

- For Thermodynamic Control (1,4-adduct): Bubble HBr gas into a solution of 1,3-butadiene at an elevated temperature (e.g., 40-50 °C). Allow the reaction to stir for several hours. Analysis will show a high proportion of 1-bromo-2-butene (1,4-adduct).

- Key Observations: Both products arise from a common resonance-stabilized allylic carbocation intermediate. At low temperatures, the nucleophile (Brâ») attacks the carbon atom in this intermediate with the highest positive charge density (typically the more substituted carbon), forming the 1,2-adduct faster. At higher temperatures, the reaction is reversible, and the product distribution shifts to favor the more stable 1,4-adduct, which features a more highly substituted alkene [7] [9].

Diagram 2: A generalized experimental workflow for selecting between kinetic and thermodynamic control in a synthetic plan.

The Researcher's Toolkit: Essential Reagents and Materials

Achieving kinetic or thermodynamic control requires careful selection of reagents and reaction conditions. The following table details key tools for steering reaction pathways.

Table 3: Research Reagent Solutions for Kinetic and Thermodynamic Control

| Reagent/Material | Function/Principle | Commonly Used For |

|---|---|---|

| Lithium Diisopropylamide (LDA) | A strong, sterically hindered base. Promotes irreversible deprotonation, favoring the kinetic (less substituted) enolate. | Kinetic enolate formation from carbonyl compounds. |

| Sodium Hydride (NaH) / Potassium Hydride (KH) | Strong, non-hindered bases. Allow for equilibration between enolates, favoring the thermodynamic (more substituted) enolate. | Thermodynamic enolate formation. |

| Low-Boiling Solvents (e.g., Diethyl Ether, Pentane) | Facilitate low-temperature reactions due to their low freezing points. Essential for quenching reactions before equilibration occurs. | Maintaining kinetic control in reactions sensitive to temperature. |

| High-Boiling Solvents (e.g., Xylene, DMSO) | Enable high-temperature reactions necessary to overcome energy barriers for product isomerization and achieve equilibrium. | Facilitating thermodynamic control. |

| Sterically Hindered Lewis Acids | Can modify the steric environment around a reaction center, potentially favoring one transition state over another based on steric, rather than electronic, factors. | Imparting kinetic selectivity in cycloadditions and other Lewis acid-catalyzed reactions. |

| Protic Solvents (e.g., Methanol, Water) | Can facilitate proton transfer, thereby enabling equilibration between isomeric products and leading to thermodynamic control. | Reactions where proton exchange is a key step in product interconversion. |

| Aprotic Solvents (e.g., THF, DMF, DMSO) | Lack acidic protons, suppressing proton transfer pathways. This helps to preserve the kinetic product once it is formed. | Reactions where the kinetic product must be isolated without isomerization. |

| O-Tolidine sulfate | O-Tolidine sulfate, CAS:531-20-4, MF:C14H16N2O4S-2, MW:308.35 g/mol | Chemical Reagent |

| Zolamine | Zolamine|C15H21N3OS|Histamine H1 Receptor Antagonist | Zolamine is an ethylenediamine-based H1 receptor antagonist and anticholinergic used in allergy research. This product is for Research Use Only (RUO). Not for human use. |

Advanced Applications and Research Implications

The principle of kinetic control extends far beyond academic model systems and is a critical consideration in modern research, including drug discovery and materials science.

Binding Kinetics in Drug Discovery: The interaction between a drug (ligand) and its biological target is a binding event governed by kinetics and thermodynamics. While the equilibrium dissociation constant (Kd) measures overall affinity, the individual association (kâ‚ or kon) and dissociation (kâ‚‚ or koff) rates are crucial. A drug with a slow dissociation rate (long residence time) can provide prolonged efficacy even after systemic concentrations have dropped, which is a desirable kinetic property for many therapeutics [10]. Modern drug discovery programs increasingly focus on optimizing these kinetic parameters, not just the overall affinity.

Kinetic Stabilization in Inorganic Synthesis: The concept of kinetic control is paramount in inorganic and materials chemistry for synthesizing metastable compounds. Many advanced materials, such as specific polymorphs of metal-organic frameworks (MOFs), complex metal clusters, or nanostructures with specific shapes, are not the thermodynamically most stable form. Their synthesis relies on carefully designed reaction conditions—such as rapid precipitation, specific capping agents, or low-temperature processing—that favor the kinetic trapping of a desired structure, preventing its conversion to a more stable, but less functional, thermodynamic product [7].

Automated Kinetic Analysis: Modern high-throughput and automated synthesis platforms are being developed to rapidly map reaction kinetics and identify optimal conditions for kinetic or thermodynamic control. These systems use transient flow experiments and computational optimization to discriminate between possible reaction models and identify kinetic parameters with minimal user input, significantly accelerating process optimization in pharmaceutical and specialty chemical development [11].

The principle of kinetic control, elegantly summarized by the maxim that "the first product formed is that which is most easily formed," is a powerful and pervasive concept in chemical synthesis [7]. By understanding and manipulating the factors that dictate reaction pathways—primarily activation energy barriers and temperature—researchers can exercise precise control over product mixtures. This allows for the targeted synthesis of either the kinetic product, with its faster formation, or the thermodynamic product, with its greater stability. As research progresses, the application of these principles continues to be refined, enabling the rational design of complex molecules, advanced materials, and more effective therapeutics through deliberate kinetic stabilization.

The Role of Activation Energy Barriers in Directing Synthesis Outcomes

In synthetic chemistry, whether organic or inorganic, the activation energy barrier is a fundamental determinant of a reaction's feasibility, rate, and outcome. It represents the minimum energy molecules must possess to undergo a successful transformation from reactants to products [12]. This energy barrier directly dictates the kinetic accessibility of a material or molecule, often outweighing thermodynamic stability in determining what can be synthesized. The ability to predict, manipulate, and overcome these barriers is therefore central to advancing synthetic capabilities, particularly in the pursuit of novel materials and pharmaceuticals.

The central challenge in synthesis is that high activation barriers, often considered insurmountable under conventional conditions, render many potentially valuable compounds inaccessible. This is especially true in inorganic materials synthesis, where reaction mechanisms are less understood than in organic chemistry, and synthesis feasibility cannot be reliably predicted from thermodynamic stability alone [2] [13]. This whitepaper explores the principles governing activation energies and details advanced experimental and computational strategies designed to overcome these barriers, with a specific focus on their implications for kinetic stabilization in inorganic materials research.

Theoretical Foundations of Activation Energy

Energy Diagrams and Reaction Kinetics

Energy diagrams provide a visual representation of the energy changes during a chemical reaction, clearly illustrating the concept of the activation energy barrier.

Diagram 1: Energy profile of an exothermic reaction

As shown in Diagram 1, the activation energy (Eâ‚) is the energy difference between the reactants and the highest point on the reaction pathway, known as the activated complex or transition state [14]. The enthalpy change (ΔH) is the difference between the potential energy of the products and reactants. In an exothermic reaction (ΔH < 0), the products are more stable than the reactants, but the reaction still requires overcoming the initial energy barrier.

The Arrhenius Law and Temperature Dependence

The relationship between activation energy, temperature, and reaction rate is quantitatively described by the Arrhenius equation: [ k = A e^{-E_a/RT} ] where k is the rate constant, A is the pre-exponential factor, Eâ‚ is the activation energy, R is the gas constant, and T is the temperature in Kelvin [12].

This relationship reveals why temperature is such a powerful lever for overcoming activation barriers. For a reaction with an activation energy of 60 kcal molâ»Â¹, the half-life decreases dramatically with increasing temperature [15] [16]:

Table 1: Relationship Between Temperature and Reaction Half-Life for High Eâ‚ Reactions

| Activation Energy (kcal molâ»Â¹) | Temperature (°C) | Approximate Half-Life (tâ‚/â‚‚) |

|---|---|---|

| 50 | 300 | 10 minutes |

| 60 | 400 | 5 minutes |

| 70 | 500 | 1 minute |

Data derived from high-temperature pyrazole isomerization studies [15] [16]

This temperature dependence enables synthetic chemists to strategically design reaction conditions to access transformations previously considered "forbidden" due to high energy barriers.

Overcoming High Activation Barriers in Organic Synthesis

High-Temperature Capillary Synthesis (HTCS)

Recent research has demonstrated that activation barriers of 50–70 kcal molâ»Â¹ can be successfully overcome in solution-phase organic synthesis through high-temperature approaches [15] [16]. Using the isomerization of N-substituted pyrazoles as a model reaction, researchers have achieved product yields up to 50% in reaction times as short as five minutes at temperatures up to 500°C [15].

The High-Temperature Capillary Synthesis (HTCS) methodology employs standard glass capillaries and p-xylene as a solvent, creating an environmentally friendly and easily reproducible system [16]. When heated to 500°C with the capillary filled to 25% of its volume with solution, the internal pressure reaches approximately 32.3 bar, potentially creating supercritical conditions that enhance reaction kinetics [16].

Table 2: HTCS Experimental Parameters and Outcomes

| Parameter | Specification | Impact on Synthesis |

|---|---|---|

| Temperature Range | Up to 500°C | Enables access to 50-70 kcal molâ»Â¹ barriers |

| Reaction Vessel | Standard glass capillaries (230 mm Duran pipettes) | Withstands ~32 bar pressure; easily accessible |

| Optimal Filling Volume | 25% of capillary volume (25 μL solution) | Prevents bursting (100% survival rate in testing) |

| Solvent | p-Xylene | Environmentally friendly; suitable for high-temperature operations |

| Typical Yield | Up to 50% | Significant for such high-barrier transformations |

| Reaction Time | As short as 5 minutes | Dramatically reduced compared to conventional methods |

DFT Modeling and Kinetic Validation

Density functional theory (DFT) calculations played a crucial role in validating this approach, revealing that the activation Gibbs energy for pyrazole isomerizations varies significantly with substituents [16]. For instance:

- 1-(2-fluoroethyl)-3-methyl-1H-pyrazole: Eâ‚ = 68.3 kcal molâ»Â¹

- 3-(1-phenyl-1H-pyrazol-2-yl)phenol: Eâ‚ = 55.4 kcal molâ»Â¹

The introduction of electron-donating or electron-withdrawing groups resulted in energy differences of less than 5 kcal molâ»Â¹, suggesting that even small energy changes enable observation of the reaction when the high barrier is overcome [16].

Predicting Synthesizability in Inorganic Materials

The Synthesis Feasibility Challenge

Unlike organic molecules, which can often be synthesized through established reaction sequences, the targeted synthesis of crystalline inorganic materials is complicated by poorly understood reaction mechanisms [2]. The decision to synthesize a particular inorganic material depends on a complex array of factors beyond simple thermodynamics, including reactant cost, equipment availability, and human-perceived importance of the final product [2].

Traditional proxies for synthesizability, such as the charge-balancing criterion, have proven inadequate. Among all inorganic materials that have already been synthesized, only 37% can be charge-balanced according to common oxidation states, and among binary cesium compounds, only 23% meet this criterion [2]. Similarly, DFT-calculated formation energies alone cannot reliably predict synthesizability because they fail to account for kinetic stabilization [2] [13].

Machine Learning Approaches

To address these challenges, deep learning models such as SynthNN (Synthesizability Neural Network) have been developed to directly predict the synthesizability of inorganic chemical formulas without requiring structural information [2]. These models leverage the entire space of synthesized inorganic chemical compositions from databases like the Inorganic Crystal Structure Database (ICSD).

Key advantages of SynthNN include:

- Broader expertise: While human experts typically specialize in specific chemical domains of a few hundred materials, SynthNN generates predictions informed by the entire spectrum of previously synthesized materials [2].

- Learned chemical principles: Without prior chemical knowledge, SynthNN learns fundamental principles like charge-balancing, chemical family relationships, and ionicity directly from the data [2].

- Performance superiority: In head-to-head material discovery comparisons, SynthNN outperformed all 20 expert material scientists, achieving 1.5× higher precision and completing tasks five orders of magnitude faster than the best human expert [2].

The following diagram illustrates the workflow for machine learning-guided synthesis prediction and its relationship to kinetic stabilization:

Diagram 2: ML workflow for synthesis prediction

Experimental Protocols and Methodologies

High-Temperature Capillary Synthesis Protocol

Materials Required:

- Glass capillaries (230 mm Duran pipettes)

- p-Xylene solvent

- Target reactants (e.g., N-substituted pyrazoles)

- Heating apparatus capable of reaching 500°C

- Safety equipment for high-pressure reactions

Step-by-Step Procedure:

- Preparation: Dissolve reactant in p-xylene at appropriate concentration.

- Loading: Fill capillary to 25% of its volume with the reaction solution (approximately 25 μL in standard capillaries).

- Sealing: Carefully seal both ends of the capillary to withstand high internal pressure.

- Heating: Place sealed capillary in preheated oven or heating block at target temperature (400-500°C).

- Reaction Monitoring: Maintain temperature for predetermined time (typically 1-10 minutes).

- Quenching: Rapidly cool the capillary to room temperature.

- Analysis: Open capillary and analyze contents using standard physicochemical methods (NMR, GC-MS, HPLC).

Critical Considerations:

- The 25% filling volume is crucial for preventing capillary bursting under pressure.

- At temperatures above 500°C, the meniscus between gas and liquid phases may disappear, suggesting the system may enter a supercritical state, potentially enhancing reaction kinetics [16].

- Safety precautions are essential when working with sealed vessels at high temperatures and pressures.

The Scientist's Toolkit: Essential Research Reagents and Materials

Table 3: Key Research Reagent Solutions for High-Barrier Synthesis

| Reagent/Material | Function/Role | Application Notes |

|---|---|---|

| High-Pressure Capillaries (Duran glass) | Withstands internal pressure up to 35 atm at 500°C | Enables high-temperature solution-phase reactions; critical for HTCS |

| p-Xylene Solvent | High-temperature solvent medium | Environmentally friendly; suitable for supercritical conditions |

| DFT Computational Tools | Models activation barriers and reaction pathways | Predicts feasibility of overcoming specific Eâ‚ values; guides experimental design |

| Machine Learning Models (SynthNN) | Predicts synthesizability of inorganic compositions | Identifies kinetically accessible materials beyond thermodynamic predictions |

| In Situ XRD | Monitors phase evolution during synthesis | Tracks formation of metastable kinetically stabilized products |

| Fenharmane | Fenharmane|High-Quality Research Chemical | Fenharmane, a β-carboline-based compound with historical research significance as a reserpine-like agent. For Research Use Only. Not for human or veterinary use. |

| N-(2-Heptyl)aniline | N-(2-Heptyl)aniline, CAS:67915-63-3, MF:C13H21N, MW:191.31 g/mol | Chemical Reagent |

Implications for Kinetic Stabilization in Inorganic Synthesis

The ability to overcome high activation barriers has profound implications for the field of kinetic stabilization in inorganic materials research. Kinetic stabilization occurs when a material persists in a metastable state due to high energy barriers that prevent its conversion to more thermodynamically stable forms.

Key implications include:

- Expanded Access to Metastable Materials: By deliberately targeting high activation energy pathways, researchers can synthesize and preserve metastable inorganic materials with unique properties not accessible through thermodynamic control.

Machine Learning-Guided Discovery: ML models like SynthNN can identify promising candidate materials with high synthesis feasibility by learning from the entire corpus of previously synthesized materials, effectively encoding patterns of kinetic accessibility [2].

Reaction Pathway Engineering: The principles demonstrated in organic HTCS can be adapted to inorganic systems, where high-temperature approaches may enable the formation of phases that are kinetically trapped upon cooling.

Rational Synthesis Design: Understanding the relationship between activation energy, temperature, and reaction rate allows for more precise engineering of synthesis conditions to target specific kinetic products.

The integration of computational guidance with advanced synthetic techniques represents a paradigm shift in materials discovery, moving beyond thermodynamic limitations to exploit kinetic stabilization as a deliberate synthesis strategy. This approach is particularly valuable for developing novel functional materials for pharmaceuticals, agrochemicals, and advanced technologies, where metastable phases often exhibit superior properties compared to their thermodynamic counterparts.

Temperature and Time as Critical Levers for Reaction Control

In the pursuit of novel inorganic materials with tailored properties, synthetic chemists increasingly target metastable compounds that are not the global thermodynamic minimum on the energy landscape. The successful synthesis of these materials depends critically on navigating complex energy landscapes through precise manipulation of kinetic stabilization. Within this paradigm, temperature and time emerge as fundamental control variables that dictate reaction pathways, phase selectivity, and ultimate material structure.

The energy landscape of materials synthesis features multiple minima representing different crystalline phases. While thermodynamics determines which state is most stable, kinetics governs the accessibility of these states during synthesis. Kinetic stabilization enables the isolation of metastable phases that would otherwise transform to more stable configurations given sufficient thermal energy or time. This technical guide examines the strategic application of temperature and time parameters to control diffusion, nucleation, and growth processes in inorganic synthesis, with particular emphasis on emerging design principles validated through robotic laboratories and computational guidance.

Theoretical Foundations of Kinetic Control

The Energy Landscape of Solid-State Reactions

Inorganic materials synthesis can be visualized as navigation through a multidimensional energy landscape where different atomic configurations correspond to energy minima separated by activation barriers [13]. The synthesis feasibility of a target material depends not only on its relative thermodynamic stability but also on the height of kinetic barriers surrounding it.

As illustrated in Figure 1, starting precursors occupy one local minimum, while the target material resides in another. The transition between these states requires overcoming an activation energy barrier (Ea) that is highly sensitive to temperature. The relationship between temperature and the rate constant (k) for a solid-state reaction is captured by the Arrhenius equation:

k = A × exp(-Ea/RT)

where A is the pre-exponential factor, R is the gas constant, and T is absolute temperature. This mathematical relationship establishes the fundamental connection between temperature and reaction kinetics that enables synthetic control.

Figure 1: Energy landscape visualization showing kinetic stabilization pathways. Strategic temperature control enables access to metastable targets while avoiding conversion to the thermodynamic phase.

Nucleation vs. Growth Kinetics

Classical nucleation theory describes the competitive processes of nucleation and crystal growth that determine final material characteristics [13]. The rate of nucleation (Rn) and growth (Rg) exhibit different temperature dependencies:

Rn ∠exp(-ΔG*/kT) × exp(-Ea,D/kT)

Rg ∠[1 - exp(-ΔG/kT)] × exp(-Ea,D/kT)

where ΔG* is the nucleation barrier, ΔG is the driving force for growth, and Ea,D is the diffusion activation energy. Temperature manipulation allows preferential acceleration of nucleation versus growth, enabling control over crystal size, morphology, and phase purity. In fluid-phase synthesis, nucleation is typically the rate-limiting step, making it particularly sensitive to temperature programming [13].

Temperature as a Synthetic Control Parameter

Temperature Windows for Phase Stabilization

Different material classes require specific temperature ranges to stabilize target phases while suppressing undesired by-products. Table 1 summarizes optimal temperature parameters for representative inorganic material systems.

Table 1: Temperature Parameters for Kinetic Stabilization in Inorganic Materials Synthesis

| Material System | Low-T Limit | High-T Limit | Optimal Range | Key Stabilized Phase |

|---|---|---|---|---|

| Chalcogenide Perovskites (SrxTiS3) | 375°C [17] | 600°C [17] | 375-600°C [17] | Incommensurate Sr8/7TiS3 |

| Quaternary Oxides (Li/Na/K-based) | Varies by system | Varies by system | 500-900°C [18] | Multicomponent oxides |

| Colloidal Nanocrystals | ~60°C (precursor prep) [17] | 380°C (injection) [17] | 60-380°C [17] [19] | Quantum dots, shaped NCs |

| High-Entropy Alloys | Ambient (precursor mixing) | >800°C (crystallization) | System-dependent [20] | Single-phase solid solutions |

The synthesis of SrxTiS3 chalcogenide perovskites exemplifies precise temperature control achieving kinetic stabilization. Traditional solid-state methods requiring temperatures exceeding 800°C produce thermodynamically favored binary sulfides, while moderate-temperature solution processing (375-600°C) successfully stabilizes the metastable incommensurate Sr8/7TiS3 phase through kinetic control [17].

Thermal Programming Strategies

Advanced thermal programming techniques enable sophisticated kinetic control:

Two-Stage Heating Profiles: Initial low-temperature ramp for precursor decomposition followed by higher-temperature crystallization. For example, copper nanocrystal synthesis employs temperature-dependent disproportionation rates of precursor complexes to control final morphology [19].

Reactive Hot-Injection: Rapid introduction of room-temperature precursors into heated reaction media creates instantaneous supersaturation, driving homogeneous nucleation. This technique achieved the first phase-pure synthesis of SrxTiS3 nanocrystals at 375-380°C [17].

Gradient Thermal Processing: Spatial or temporal temperature gradients selectively promote desired reaction pathways while suppressing side reactions, particularly valuable in multicomponent oxide synthesis [18].

Temporal Control in Reaction Engineering

Critical Time Scales in Synthesis

Time parameters interact with temperature to determine reaction outcomes across multiple stages. Table 2 outlines key temporal parameters in the inorganic synthesis workflow.

Table 2: Time Parameters in Inorganic Materials Synthesis Protocols

| Synthesis Stage | Time Scale | Impact on Reaction | Kinetic Influence |

|---|---|---|---|

| Precursor Preparation | Minutes to hours [17] | Determines molecular homogeneity | Affects nucleation barrier |

| Nucleation | Milliseconds to seconds [19] | Sets primary particle count | Defines initial phase selection |

| Crystal Growth | Minutes to hours [17] [19] | Controls size, morphology, and defects | Governs Ostwald ripening processes |

| Phase Transformation | Hours to days [18] | Determines final phase purity | Impacts kinetic trapping of metastable phases |

| Annealing | Minutes to hours [17] | Modifies crystallinity and composition | Enables defect engineering |

Dwell Time Optimization

The reaction dwell time at maximum temperature critically influences phase evolution. In the synthesis of multicomponent oxides, extended dwell times often allow thermodynamically favored impurity phases to nucleate and grow, consuming the driving force needed to form target materials [18]. Strategic limitation of dwell time can kinetically trap desired metastable phases.

For SrxTiS3 thin films, a 30-minute dwell time at the maximum temperature (below 600°C) proved sufficient to form phase-pure material while avoiding decomposition to binary sulfides [17]. Similarly, in colloidal nanocrystal synthesis, precise timing of the growth phase determines size distribution and crystallographic defects [19].

Experimental Protocols for Kinetic Control

Moderate-Temperature Synthesis of SrxTiS3 Nanocrystals

The following protocol demonstrates temperature and time control for kinetically stabilizing metastable chalcogenide perovskites [17]:

Materials and Equipment:

- Schlenk line with argon purification

- Heating mantle with temperature controller

- Oleylamine (OLA), carbon disulfide (CS2), mineral oil

- Sr(iPr3Cp)2 and TEMAT precursors

- Toluene and isopropanol for washing

Procedure:

- Precursor Preparation (Room Temperature, 10-15 minutes): In a nitrogen-filled glovebox, dissolve Sr(iPr3Cp)2 (1.1 mmol) and TEMAT (1.0 mmol) in oleylamine (5 mL). Add 20-fold molar excess of CS2 relative to Sr precursor. The solution becomes slightly viscous due to oleyldithiocarbamic acid formation.

Reaction Setup (60°C, 10 minutes): Preheat the OLA-CS2 solution to 60°C to decrease viscosity while maintaining homogeneity. Separately, heat mineral oil (15 mL) in the reaction flask to 375-380°C under argon purge.

Hot-Injection (375-380°C, instantaneous): Rapidly inject the precursor solution into heated mineral oil. Immediate black coloration indicates Sr–Ti–S nanocrystal nucleation.

Crystal Growth (375-380°C, 30 minutes): Maintain temperature for 30 minutes to allow controlled nanocrystal growth. Sulfur-containing species may condense on condenser walls during this stage.

Quenching (Room Temperature, natural cooling): Turn off heating mantle and allow natural cooling to room temperature. Transfer reaction contents to glovebox for washing.

Purification (Room Temperature, 20 minutes): Wash products with toluene and isopropanol (toluene as solvent, isopropanol as antisolvent). Collect dark blackish pellet by centrifugation and redisperse in toluene.

Key Kinetic Control Elements: The hot-injection technique creates instantaneous supersaturation, driving homogeneous nucleation of the metastable phase. Controlled growth at moderate temperature (375-380°C) prevents transformation to thermodynamically stable binaries. The 30-minute dwell time optimizes crystallinity without enabling phase separation.

Precursor Selection for Enhanced Kinetics

Beyond direct temperature and time control, precursor selection significantly impacts kinetic pathways by modifying reaction energy landscapes [18]:

Figure 2: Precursor engineering redirects kinetic pathways. High-energy precursors enable direct routes to target materials, while traditional precursors often form kinetic traps.

Protocol for Precursor Evaluation:

- Construct Phase Diagram: Map competing phases in the chemical space between precursors and target using computational thermodynamics databases [18].

Calculate Reaction Energetics: Compute pairwise reaction energies between potential precursors to identify combinations that maximize driving force to the target while minimizing stable intermediates [18].

Select High-Energy Precursors: Choose precursors that position the target as the deepest point in the local convex hull, ensuring greater thermodynamic driving force to the target than to competing phases [18].

Validate Experimentally: Test predicted precursor combinations using robotic synthesis platforms for high-throughput validation across diverse chemical systems [18].

The Scientist's Toolkit: Essential Research Reagents

Table 3: Key Reagent Solutions for Kinetic-Controlled Inorganic Synthesis

| Reagent/Chemical | Function in Synthesis | Role in Kinetic Control |

|---|---|---|

| Oleylamine (OLA) | Reaction solvent and surfactant | Modifies nucleation kinetics through surface stabilization [17] |

| Carbon Disulfide (CS2) | Sulfur source | Forms dithiocarbamate complexes that decompose at controlled rates [17] |

| Trioctylphosphine Oxide (TOPO) | Coordination ligand | Drives reaction equilibria and controls monomer release kinetics [19] |

| Metal Amides (e.g., TEMAT) | Reactive metal precursors | Lower decomposition temperatures compared to traditional salts [17] |

| Mineral Oil | High-temperature solvent | Provides stable thermal environment for nanocrystal growth [17] |

| 3,5-Octadien-2-ol | 3,5-Octadien-2-ol CAS 69668-82-2|Research Chemical | High-purity 3,5-Octadien-2-ol for research. A key dienol used in organic synthesis and flavor/fragrance studies. For Research Use Only. Not for human or veterinary use. |

| 3-Pyridinealdoxime | 3-Pyridinealdoxime, CAS:51892-16-1, MF:C6H6N2O, MW:122.12 g/mol | Chemical Reagent |

Emerging Approaches: Machine Learning and Automation

Data-Driven Synthesis Optimization

Traditional One-Factor-at-a-Time (OFAT) approaches to temperature and time optimization are increasingly supplemented by machine learning (ML) methods that efficiently navigate complex parameter spaces [21] [13] [22]. ML techniques excel at identifying non-intuitive parameter combinations that kinetically stabilize target materials:

Neural Network Prediction: ML models trained on high-throughput experimentation data can recommend optimal temperature parameters for new chemical systems with approximately 50% accuracy in top-3 predictions [22].

Multi-Objective Optimization: Advanced algorithms balance competing objectives (yield, phase purity, particle size) when optimizing temperature-time profiles [22].

Robotic Validation: Automated synthesis laboratories enable rapid testing of ML-predicted conditions, dramatically accelerating the optimization cycle [18].

In Situ Characterization for Kinetic Monitoring

Real-time monitoring techniques provide unprecedented insight into temperature- and time-dependent reaction pathways:

In Situ X-Ray Scattering: Reveals phase evolution and structural changes during heating, enabling identification of kinetic intermediates [19].

Optical Spectroscopy: Tracks nanocrystal formation and growth kinetics, correlating specific temperature thresholds with nucleation events [19].

Mass Spectrometry: Identifies molecular intermediates and decomposition pathways during thermal processing [19].

Temperature and time represent powerful, interdependent levers for controlling reaction pathways in inorganic materials synthesis. Through strategic application of thermal programming and temporal parameters, synthetic chemists can kinetically stabilize metastable phases that exhibit promising functional properties. The continuing integration of computational guidance, machine learning optimization, and robotic validation promises to transform kinetic control from an empirical art to a predictive science, accelerating the discovery and synthesis of next-generation materials.

The concept of kinetic control is a cornerstone of synthetic chemistry, enabling the selective formation of metastable products that are not the thermodynamically most stable species in a system. This principle is particularly vital in inorganic synthesis research, where the targeted materials often exist in metastable states characterized by a Gibbs free energy higher than the equilibrium state, persisting due to kinetic constraints [23]. The ability to navigate complex energy landscapes and selectively isolate these kinetically trapped intermediates is what allows access to a vast array of functional materials with properties unattainable from their thermodynamic counterparts.

This case study examines the foundational organic reactions where these principles are most clearly demonstrated: the Diels-Alder cycloaddition and electrophilic addition to conjugated dienes. These reactions provide exemplary models for understanding how reaction parameters, primarily temperature, can dictate product distribution by shifting the reaction regime from kinetic to thermodynamic control. A deep understanding of these model systems provides a critical framework for developing advanced synthetic protocols in inorganic and materials chemistry, where predicting and controlling synthesizability remains a significant challenge [24].

Theoretical Foundations of Reaction Control

In any chemical reaction capable of yielding multiple products, the final product distribution is determined by the reaction conditions and the fundamental energetics of the reaction pathway.

- Kinetic Control: This regime dominates under low-temperature, irreversible conditions. The major product is the one that forms the fastest, meaning it has the lowest activation energy barrier ((E_a)) for its formation. This product is referred to as the kinetic product.

- Thermodynamic Control: This regime dominates under higher-temperature, reversible conditions. The reaction achieves equilibrium, and the major product is the most stable one, with the lowest free energy ((G)). This product is referred to as the thermodynamic product.

The following conceptual diagram illustrates the energy landscape for a generic reaction under kinetic and thermodynamic control.

- TSK and TST represent the transition states for the formation of the kinetic and thermodynamic products, respectively. The kinetic product forms faster due to the lower energy of TS_K.

- The dashed arrow indicates that at high temperatures, the kinetic product can revert and proceed to form the more stable thermodynamic product, establishing an equilibrium [25] [26].

Kinetic Control in the Diels-Alder Reaction

The Diels-Alder reaction, a [4+2] cycloaddition between a diene and a dienophile, is a powerful tool for constructing six-membered rings with precise stereochemistry and is extensively used in the total synthesis of natural products [27]. A key stereochemical feature of this reaction is the formation of endo and exo diastereomers.

The Endo Rule and Kinetic Preference

The endo product, where the electron-withdrawing groups of the dienophile are oriented towards the π-system of the diene, is typically the major product under standard, kinetically controlled conditions. This preference, known as the endo rule, arises from secondary orbital interactions that stabilize the transition state leading to the endo product, thereby lowering its activation energy compared to the exo pathway [27] [25]. For instance, the dimerization of cyclopentadiene yields a 9:1 ratio favoring the endo adduct at room temperature [27].

Thermodynamic Reversal and the Retro-Diels-Alder

The Diels-Alder reaction is reversible at elevated temperatures through a retro-Diels-Alder process [25]. This reversibility is famously demonstrated by dicyclopentadiene, which reverts to cyclopentadiene upon heating to 180°C. When the reaction is reversible, the product distribution reflects the relative stabilities of the products. The exo product is often less sterically hindered and thermodynamically more stable. Therefore, under thermodynamic control (e.g., heating cyclopentadiene at 200°C for two days), the exo product proportion increases significantly, with the endo:exo ratio shifting to 4:1 [25].

Table 1: Product Control in the Diels-Alder Reaction of Cyclopentadiene

| Parameter | Kinetic Control (Low Temperature) | Thermodynamic Control (High Temperature) |

|---|---|---|

| Major Product | endo adduct | exo adduct |

| Basis of Control | Lower activation energy for endo TS (secondary orbital interactions) | Greater thermodynamic stability of exo product (less steric strain) |

| Reversibility | Irreversible | Reversible (equilibrium established via retro-Diels-Alder) |

| Example | Endo:Exo ≈ 9:1 at 23°C [27] | Endo:Exo ≈ 4:1 at 200°C [25] |

Experimental Protocol: Demonstrating Diels-Alder Kinetic Control

Objective: To demonstrate the kinetic endo-selectivity in the Diels-Alder reaction between cyclopentadiene and maleic anhydride.

Materials:

- Dicyclopentadiene (precursor for cyclopentadiene)

- Maleic anhydride

- Anhydrous diethyl ether (dry to prevent hydrolysis of maleic anhydride)

- Ethyl acetate (for recrystallization)

Procedure:

- Crack dicyclopentadiene by thermally decomposing it via simple distillation at ~180°C to obtain fresh, monomeric cyclopentadiene. The distillate must be kept cold and used promptly [25].

- Dissolve maleic anhydride in a minimal volume of anhydrous diethyl ether in a round-bottom flask.

- Cool the flask in an ice-water bath (0°C).

- Slowly add a stoichiometric equivalent of freshly cracked cyclopentadiene to the chilled maleic anhydride solution with stirring.

- Allow the reaction to proceed for 30-60 minutes in the ice bath. A white crystalline solid should form.

- Collect the product by vacuum filtration and wash with cold ether.

- Recrystallize the crude product from ethyl acetate.

- Characterize the product by determining its melting point and obtaining ( ^1H )-NMR spectra. The melting point and NMR coupling constants can be compared to literature values for the endo and exo adducts to confirm the formation of the kinetic endo product.

Kinetic Control in Electrophilic Addition to Dienes

Conjugated dienes undergo electrophilic addition (e.g., with HBr) to yield a mixture of products: one from direct, 1,2-addition and another from 1,4-addition (or conjugate addition).

The Role of the Resonance-Stabilized Carbocation

The mechanism begins with protonation of the diene, generating a resonance-stabilized allylic carbocation intermediate. This carbocation hybrid can be represented by two resonance forms, leading to two different sites for nucleophilic attack [26].

- 1,2-adduct: Results from nucleophilic attack at the carbon atom bearing the initial partial positive charge (often the more substituted carbon). This product typically has a less substituted, monosubstituted alkene.

- 1,4-adduct: Results from nucleophilic attack at the terminal carbon of the allylic system. This product features a new, more substituted (disubstituted) alkene.

Temperature-Dependent Product Distribution

The choice between these products is exquisitely sensitive to temperature.

- Low Temperatures (Kinetic Control): The reaction is irreversible. The 1,2-adduct is formed faster because its transition state benefits from more complete charge stabilization at the more substituted carbon center. It is the kinetic product [28] [26].

- High Temperatures (Thermodynamic Control): The reaction becomes reversible. The carbocation can re-form from both products. An equilibrium is established that favors the 1,4-adduct because it possesses the more stable, more substituted alkene. It is the thermodynamic product [26].

Table 2: Product Control in the Electrophilic Addition of HBr to 1,3-Butadiene

| Parameter | Kinetic Control (Low Temperature) | Thermodynamic Control (High Temperature) |

|---|---|---|

| Major Product | 1,2-adduct (3-bromo-1-butene) | 1,4-adduct ((E)-1-bromo-2-butene) |

| Basis of Control | Lower activation energy for 1,2-addition (more stable carbocation character in TS) | Greater thermodynamic stability of 1,4-product (more substituted alkene) |

| Reversibility | Irreversible | Reversible (via reformation of allylic carbocation) |

| Example Ratio | 1,2:1,4 ≈ 70:30 at -80°C | 1,2:1,4 ≈ 15:85 at 40°C [26] |

The energy diagram below maps this reaction pathway, showing the critical role of the resonance-stabilized intermediate.

Experimental Protocol: Demonstrating 1,2- vs. 1,4-Addition

Objective: To observe the temperature-dependent product ratio in the addition of HBr to 1,3-butadiene.

Materials:

- 1,3-Butadiene (gas, can be generated from a precursor or used from a cylinder)

- Anhydrous HBr (gas)

- Anhydrous pentane or dichloromethane as solvent

- Cold baths (e.g., dry ice/acetone at -78°C and a water bath at 40°C)

Procedure:

- Set Up Two Reaction Vessels: Equip two flame-dried round-bottom flasks with septa and magnetic stir bars. Purge with inert gas.

- Cooling/Heating: Charge both flasks with solvent and 1,3-butadiene. Cool one flask to -78°C. Warm the other flask to 40°C.

- Addition of HBr: Bubble a slow, steady stream of anhydrous HBr gas into each solution with vigorous stirring. Maintain the respective temperatures during addition.

- Work-up: After a set time, quench both reactions by pouring into a saturated sodium bicarbonate solution.

- Analysis: Separate the organic layers and analyze by gas chromatography (GC). The relative ratios of the 1,2- and 1,4-adducts can be determined from the GC chromatograms. The low-temperature reaction will show a higher proportion of the 1,2-adduct, while the high-temperature reaction will show a higher proportion of the 1,4-adduct [26].

The Scientist's Toolkit: Essential Research Reagents

Table 3: Key Reagents for Studying Kinetic Control

| Reagent | Function in Study |

|---|---|

| Cyclopentadiene | A highly reactive diene that undergoes facile Diels-Alder reactions and dimerization, making it ideal for studying endo/exo selectivity and reversibility [25]. |

| Maleic Anhydride | A highly reactive dienophile; its electron-withdrawing carbonyl groups strongly influence the endo/exo selectivity in Diels-Alder reactions [25]. |

| 1,3-Butadiene | The prototypical conjugated diene for studying 1,2- versus 1,4-electrophilic addition regio- and stereochemistry [26]. |

| Anhydrous HBr | A strong acid source for electrophilic addition to dienes; anhydrous conditions prevent side reactions and ensure accurate product distribution analysis [26]. |

| Titanium Nitride (TiN) Nanoparticles | Advanced photothermal catalysts that allow spatial and temporal control of heat to drive Diels-Alder reactions, enabling studies of kinetics under novel energy input modes [29]. |

| C15H16Cl3NO2 | C15H16Cl3NO2, MF:C15H16Cl3NO2, MW:348.6 g/mol |

| 1-bromohept-1-yne | 1-Bromohept-1-yne|C7H11Br|CAS 19821-84-2 |

Implications for Kinetic Stabilization in Inorganic Synthesis

The principles elucidated by these classic organic reactions directly inform cutting-edge research in inorganic materials synthesis. The synthesis of metastable inorganic phases—materials with a Gibbs free energy higher than the equilibrium state—relies on precisely manipulating kinetic and thermodynamic factors [23].

For example, the synthesis of metastable polymorphs of common materials (e.g., 2M-WSâ‚‚) leverages rapid precipitation, specific precursor decompositions, or template effects to kinetically trap intermediates along a complex transformation pathway, preventing reorganization into the thermodynamically stable bulk phase [23]. This is the inorganic synthesis analogue of running a Diels-Alder reaction at low temperature to isolate the kinetic endo product. The failure of traditional thermodynamic metrics (e.g., energy above hull) to reliably predict synthesizability has spurred the development of machine learning models, such as the Crystal Synthesis Large Language Model (CSLLM), which can more accurately identify synthesizable crystal structures by learning complex, kinetically influenced patterns from experimental data [24].

The Diels-Alder and electrophilic addition reactions serve as fundamental paradigms for kinetic control. The deliberate selection of temperature to govern product formation—favoring either the kinetically favored endo or 1,2-adduct, or the thermodynamically favored exo or 1,4-adduct—is a powerful strategy. Mastering these principles provides a critical conceptual framework for tackling one of the most significant challenges in modern materials science: the rational design and synthesis of metastable functional materials. As research progresses, the integration of classic chemical intuition with advanced computational predictions will be crucial for navigating complex energy landscapes and discovering novel, kinetically stabilized compounds.

Stabilization Strategies in Practice: From Protein Drugs to Advanced Materials

Enhancing Kinetic Stability in Enzymes via Active Site Rigidification

Kinetic stability, defined as an enzyme's resistance to irreversible inactivation under challenging conditions, is a critical parameter for industrial biocatalysis. While traditional stabilization strategies often targeted surface residues or global rigidity, emerging evidence indicates that the active site is a particularly fragile region, often more susceptible to denaturation than the enzyme as a whole. This technical review examines the paradigm of active site rigidification as a targeted approach to enhance kinetic stability. We synthesize current methodologies including B-factor guided mutagenesis, short-loop engineering, and machine learning-driven design, presenting quantitative stability data across diverse enzyme classes. The review also addresses the crucial balance between stabilizing rigidity and maintaining catalytic flexibility, providing detailed experimental protocols and reagent solutions for research implementation. Within the broader context of kinetic stabilization in inorganic synthesis, these enzyme engineering strategies offer sustainable pathways for developing robust industrial biocatalysts.

Enzyme stability is typically categorized into two distinct concepts: thermodynamic stability, which measures the free energy difference between folded and unfolded states, and kinetic stability, which refers to the resistance to irreversible inactivation over time under denaturing conditions. For industrial applications, kinetic stability is often more relevant as it directly correlates with an enzyme's operational lifespan and functional resilience [30].

Comparative studies of enzyme conformation and activity during denaturation have revealed that the active site often displays greater fragility than the overall protein structure. Even before global unfolding occurs, minor conformational fluctuations in the active site can lead to complete activity loss. This observation forms the rationale for targeted rigidification of active site regions rather than pursuing global protein stabilization [30].

The molecular basis of kinetic stability revolves around the energy barrier for irreversible inactivation. By introducing mutations that increase this energy barrier, engineers can significantly extend the functional lifetime of enzymes. Active site rigidification achieves this by reducing conformational flexibility in catalytically crucial regions, thereby protecting the precise spatial arrangement of residues necessary for activity [30].

Theoretical Foundation: Molecular Mechanisms of Rigidification

Structural Determinants of Active Site Flexibility

The active site is not a static architectural feature but a dynamic region whose flexibility is essential for substrate binding, catalysis, and product release. However, excessive flexibility renders the site vulnerable to thermal disruption. Several structural factors contribute to active site flexibility:

- Loop dynamics: Short loops near active sites often exhibit high mobility and can be targets for stabilization [31]

- Solvent exposure: Active site residues are frequently partially solvent-accessible, increasing their susceptibility to denaturing agents

- Evolutionary constraints: Catalytic residues are often conserved at the expense of stability, creating natural stability-activity tradeoffs

Rigidification Strategies and Their Structural Consequences

| Strategy | Molecular Mechanism | Structural Outcome |

|---|---|---|

| B-factor guided mutagenesis | Targeting high B-factor residues for mutation to more rigid conformations | Reduced atomic displacement parameters, decreased thermal motion [30] |

| Short-loop engineering | Mutating sensitive residues on short loops to hydrophobic residues with large side chains | Cavity filling, enhanced hydrophobic packing, restricted loop mobility [31] |

| Hydrogen bond engineering | Introducing new main chain hydrogen bond networks | Stabilization of secondary structural elements, particularly helices near active sites [30] |

| Distal mutation effects | Mutating residues outside active site to modulate conformational dynamics | Altered allosteric networks, optimized catalytic cycle efficiency [32] |

Experimental Methodologies and Workflows

B-Factor Analysis and Targeted Mutagenesis

Objective: Identify flexible active site residues through crystallographic B-factor analysis and stabilize them through mutagenesis.

Protocol:

- Obtain crystal structure: Source enzyme structure from PDB (e.g., 1TCA for Candida antarctica lipase B)

- B-factor analysis: Identify residues within 10Ã… of catalytic residues with highest B-factors using tools like PyMol or Chimera

- Residue selection: Filter for residues not directly involved in catalysis but with high thermal mobility

- Saturation mutagenesis: Create ISM (Iterative Saturation Mutagenesis) libraries at target positions using NNK/MNN degeneracy

- High-throughput screening: Plate libraries on agar plates with substrate indicators (e.g., tributyrin emulsified in gum arabic)

- Characterization: Measure half-life at elevated temperatures and T50 (temperature at which 50% activity is lost after 15min) [30]

Key Reagents:

- Tributyrin emulsified in 0.4% gum arabic (screening indicator)

- Appropriate bacterial expression system (e.g., E. coli Rosetta with pET-22b vector)

- PrimeSTAR polymerase for high-fidelity library construction

Short-Loop Engineering Protocol

Objective: Stabilize short loops near active sites by introducing large, hydrophobic residues.

Protocol:

- Identify short loops: Locate loops of 4-10 residues proximal to active site

- Select "sensitive residues": Identify rigid but sensitive positions within these loops

- Hydrophobic cavity filling: Design mutations to hydrophobic residues with large side chains (e.g., Phe, Trp, Tyr)

- Library construction: Focused mutagenesis at sensitive residue positions

- Stability screening: Express variants and measure half-life improvements under denaturing conditions [31]

Machine Learning-Guided Rigidification

Objective: Use computational models to predict stabilizing mutations that enhance kinetic stability.

Protocol:

- Dynamic squeezing index (DSI) calculation: Compute DSI values for all residues (>0.8 indicates high fluctuation)

- Isothermal compressibility analysis: Identify high-fluctuation regions through molecular dynamics

- Free energy prediction: Calculate ΔΔG for mutations using Rosetta or FoldX

- Variant ranking: Combine DSI, fluctuation analysis, and ΔΔG to prioritize mutations

- Experimental validation: Test top candidates for activity and stability [33]

Figure 1: Experimental workflow for enhancing enzyme kinetic stability through active site rigidification, integrating multiple computational and experimental approaches.

Quantitative Stability Enhancements Across Enzyme Classes

Documented Stability Improvements

| Enzyme | Mutation Strategy | Half-life Improvement | T50 Increase | Catalytic Efficiency (kcat/KM) | Reference |

|---|---|---|---|---|---|

| Candida antarctica lipase B | D223G/L278M (active site high B-factor) | 13-fold at 48°C | +12°C | Maintained | [30] |

| Lactate dehydrogenase (Pediococcus pentosaceus) | Short-loop engineering | 9.5-fold | Not reported | Maintained/Improved | [31] |

| Urate oxidase (Aspergillus flavus) | Short-loop engineering | 3.11-fold | Not reported | Maintained/Improved | [31] |

| D-lactate dehydrogenase (Klebsiella pneumoniae) | Short-loop engineering | 1.43-fold | Not reported | Maintained/Improved | [31] |

| HG3 Kemp eliminase | Core active site mutations | Not reported | Not reported | 90-fold increase | [32] |

| Xylanase (Bacillus halodurans) | iCASE strategy (R77F/E145M/T284R) | Not reported | +2.4°C | 3.39-fold increase | [33] |

Structural Correlations with Stability Enhancements

Rigidification strategies yield quantifiable structural changes that correlate with stability improvements:

- Reduced B-factors: Mutants show decreased atomic displacement parameters in active site regions

- Hydrogen bond networks: Introduction of new main chain hydrogen bonds (e.g., 7 additional bonds in CalB D223G/L278M mutant)

- Cavity filling: Reduced void volumes in active site regions through large hydrophobic side chains

- Dynamic squeezing: Lower DSI values indicating restricted fluctuations near active sites [30] [33]

The Stability-Activity Tradeoff and Balancing Strategies

A significant challenge in active site rigidification is the potential negative impact on catalytic activity. Overly rigid active sites may compromise the conformational flexibility needed for substrate binding, catalysis, and product release.