Bottling Chemistry: How AI is Quantifying Human Intuition to Accelerate Inorganic Materials Discovery

This article explores the transformative integration of human chemical intuition with artificial intelligence for discovering novel inorganic materials.

Bottling Chemistry: How AI is Quantifying Human Intuition to Accelerate Inorganic Materials Discovery

Abstract

This article explores the transformative integration of human chemical intuition with artificial intelligence for discovering novel inorganic materials. It covers the foundational concept of chemical intuition as an unwritten guide for experimentalists, examines new methodologies like the Materials Expert-AI (ME-AI) framework that translate this intuition into quantitative descriptors, and addresses challenges in data curation and model interpretability. Highlighting real-world applications from quantum materials to metal-organic frameworks, it presents validation studies demonstrating that human-AI teams outperform either alone. The discussion extends to future implications for accelerating the development of advanced materials for energy, electronics, and biomedical applications.

The Unwritten Rules: Defining Chemical Intuition in Materials Science

What is Chemical Intuition? From Heuristics to Quantitative Descriptors

Chemical intuition represents the accumulated knowledge, experience, and pattern recognition capabilities that enable researchers to make educated predictions about chemical behavior, reactivity, and properties. In the context of drug design and discovery, it encompasses the medicinal chemist's ability to process large sets of data containing chemical descriptors, pharmacological data, pharmacokinetics parameters, and computational predictions to make strategic decisions in lead optimization and development [1]. This human cognition, experience, and creativity component remains fundamental to drug research, serving as a crucial complement to increasingly sophisticated computational tools.

In modern materials science, this intuition is being systematically encoded into quantitative descriptors and machine learning frameworks, creating a powerful synergy between human expertise and data-driven discovery. As researchers pursue materials with specialized functionalities for energy and sustainability applications, they are transforming chemical intuition from an implicit "gut feeling" into explicit, computable parameters that can guide autonomous experimentation and high-throughput screening [2]. This transition represents a paradigm shift in how chemists approach the discovery of new materials, moving from purely trial-and-error approaches to prediction-driven synthesis.

The Evolution from Heuristics to Quantitative Descriptors

Traditional Heuristic Approaches

Traditional materials discovery has historically relied on chemical intuition guided by decades of trial-and-error experiments. Researchers would synthesize substances and tweak experimental conditions based on empirical rules and laboratory experience, generating new versions until a material emerged with the desired properties [2]. This process consumed significant time, resources, and molecular building blocks, with success heavily dependent on the researcher's individual expertise and pattern recognition capabilities.

In drug discovery, this heuristic approach manifested in medicinal chemists relying on structure-activity relationships (SAR) to guide lead optimization campaigns. This process required dealing with large datasets of chemical structures and biological responses to identify meaningful patterns that could inform molecular design [1]. While often successful, this intuition-driven approach suffered from limitations in scalability and transferability, as the implicit knowledge of experienced chemists was difficult to formalize and communicate.

The Rise of Quantitative Descriptors

The limitations of purely heuristic approaches prompted the development of quantitative descriptors that could encode chemical information in computer-interpretable formats. Molecular descriptors represent diverse structural and physico-chemical characteristics of molecules, ranging from simple structural fingerprints to complex geometrical descriptions [3] [4]. These descriptors serve as numerical representations of molecular structures, enabling computational analysis and prediction of material properties.

Table 1: Classes of Molecular Descriptors and Their Applications

| Descriptor Class | Examples | Key Features | Applications in Materials Discovery |

|---|---|---|---|

| Structural Fingerprints | Extended Connectivity Fingerprints (ECFPs) [4] | Encode structural features based on atom environments and connectivity | Virtual screening, similarity searching, and clustering of compounds |

| Physicochemical Descriptors | Abraham solvation parameters [4] | Encode molar volume, H-bond acidity/basicity, polarity/polarizability | Predicting solubility, partitioning behavior, and linear free energy relationships |

| Geometrical Descriptors | Smooth Overlap of Atomic Positions (SOAP) [4] | Describe local atomic environments using parametrizable density-based representations | Stability prediction of organic compounds in condensed and gas phases |

| Topological Descriptors | Degree of π Orbital Overlap (DPO) [5] | Capture π-conjugation patterns in polyaromatic systems using polynomial parameters | Predicting electronic properties (band gaps, ionization potentials) of PAHs and thienoacenes |

| Information-Theoretic Descriptors | Conditional entropy, mutual information [6] | Quantify electron delocalization and information flow in molecular systems | Characterizing covalent and ionic components of chemical bonds |

The descriptor-based approach has evolved significantly, with modern software tools like AlvaDesc capable of generating up to 5,666 distinct descriptors for each molecule [3]. This high-dimensional representation contains rich information about molecular structures, increasing the likelihood of capturing relevant features affecting target properties, though it also introduces challenges related to dimensionality and interpretability.

Chemical Intuition in Inorganic Materials Discovery

Computational Search Strategies

In inorganic materials discovery, chemical intuition has been formalized through computational search strategies that can explore compositional and structural spaces more efficiently than traditional methods. Alex Zunger's work at the University of Colorado, Boulder exemplifies this approach, using first-principles thermodynamics to identify "missing" compounds that should be stable based on computational predictions but haven't yet been synthesized [2]. This strategy demonstrated its power when researchers synthesized 15 of these predicted compounds and found that all of them matched the predicted structures, validating the computational approach.

The transition from heuristic to quantitative approaches is particularly valuable for discovering materials with specific functionalities for energy technologies. As Zunger notes, "We understand the functionality needed for many technologies, but often we do not have the materials that provide those functionalities" [2]. Computational searches enable researchers to explore how a material's properties change as a function of parameters that cannot be controlled experimentally, uncovering predictive and sometimes hidden trends among classes of materials.

Descriptor-Driven Discovery Frameworks

Modern materials discovery frameworks increasingly integrate chemical intuition directly into machine learning models. The TXL Fusion framework represents a cutting-edge example, explicitly integrating three complementary pillars: (1) composition-driven chemical heuristics, (2) domain-specific numerical descriptors, and (3) embeddings derived from fine-tuned large language models (LLMs) [7].

In this framework, chemical heuristics capture global compositional trends consistent with chemical intuition—for instance, that lighter, nonmetallic elements tend to favor trivial phases, while heavier elements like Bi, Sb, and Te correlate with topological behavior [7]. These heuristics are then complemented by numerical descriptors encoding physically meaningful quantities such as space group symmetry, electron counts, orbital occupancies, and electronegativity differences. The LLM component adds the ability to process unstructured information from scientific literature and material descriptions, capturing contextual relationships that might be missed by manual feature engineering.

Table 2: Quantitative Descriptors for Topological Materials Discovery in TXL Fusion Framework [7]

| Descriptor Category | Specific Descriptors | Physical Significance | Performance in Classification |

|---|---|---|---|

| Structural Symmetry | Space group symmetry | High-symmetry cubic/tetragonal groups favor topological semimetals; low-symmetry monoclinic/orthorhombic favor trivial compounds | Emerged as most decisive indicator of topological character |

| Electronic Structure | Valence electron configuration, d- and f-orbital participation, electron-count parity | Band inversion mechanisms, strong spin-orbit coupling, metallicity requirements | Differentiates metallic TSMs (70.7% have odd electron counts) from insulating TIs |

| Compositional Features | Elemental contribution scores (Topogivity), heavy element content | Chemical intuition encoding: heavier elements promote topological states | Identifies tendency for topological behavior but cannot distinguish TI vs TSM alone |

| Bonding Characteristics | Covalent vs ionic character descriptors | Role of delocalized orbitals in stabilizing nontrivial topology | TIs and TSMs preferentially adopt mostly covalent character versus trivials |

The integration of these complementary descriptor types enables a more robust and interpretable discovery process than any single approach alone. As the developers note, this hybrid framework "unites symbolic, statistical, and linguistic knowledge" to address complex discovery challenges in materials science [7].

Experimental Protocols and Methodologies

QSPR Model Development Protocol

The development of Quantitative Structure-Property Relationship (QSPR) models follows a systematic protocol that transforms chemical intuition into predictive algorithms. A comprehensive methodology for developing descriptor-based machine learning models for thermodynamic properties involves several key stages [3]:

Data Collection and Curation: Compiling a dataset of experimental values for the target property (e.g., enthalpy of formation, entropy, solubility). For solubility prediction in lipids, this involves determining drug solubility in medium-chain triglycerides (MCT) using methods like the miniaturized 96-well assay for solubility and residual solid screening (SORESOS) or shake-flask methods, followed by solid-state characterization via powder X-ray diffraction to identify potential solid-state changes [4].

Descriptor Calculation and Preprocessing: Generating molecular descriptors using software tools like RDKit, AlvaDesc, or PaDEL. This step produces high-dimensional descriptor vectors (e.g., 5,666 descriptors per molecule in AlvaDesc) that require customized preprocessing techniques to improve data quality while limiting information loss [3].

Dimensionality Reduction: Applying feature selection methods like genetic algorithms to automatically identify the most important descriptors, or feature extraction methods to project the original high-dimensional space into a lower-dimensional representation. This step addresses the "curse of dimensionality" and improves model interpretability [3].

Model Construction and Validation: Training machine learning models (e.g., Lasso linear models, gradient-boosted trees) using the selected descriptors and validating according to OECD principles—including defined endpoints, unambiguous algorithms, applicability domains, and appropriate measures of goodness-of-fit, robustness, and predictivity [3].

This protocol explicitly incorporates chemical intuition through the initial descriptor selection and the iterative refinement of models based on physical interpretation of the most relevant descriptors.

Autonomous Discovery Workflows

Recent advances have introduced autonomous experimentation workflows that close the loop between prediction and validation. The A-Lab system developed at Lawrence Berkeley National Laboratory exemplifies this approach, using AI to synthesize compounds predicted by density functional theory (DFT) but never previously prepared [8]. The system controls robotic instrumentation to perform experiments, analyzes whether products meet specifications, and adjusts formulations as needed, achieving fully autonomous optimization.

Flow-driven data intensification represents another cutting-edge methodology that accelerates materials discovery by continuously mapping transient reaction conditions to steady-state equivalents. Applied to inorganic materials syntheses such as CdSe colloidal quantum dots, this approach yields at least an order-of-magnitude improvement in data acquisition efficiency while reducing both time and chemical consumption compared to state-of-the-art self-driving fluidic laboratories [9]. This methodology fundamentally redefines data utilization in autonomous materials research by integrating real-time, in situ characterization with microfluidic principles and autonomous experimentation.

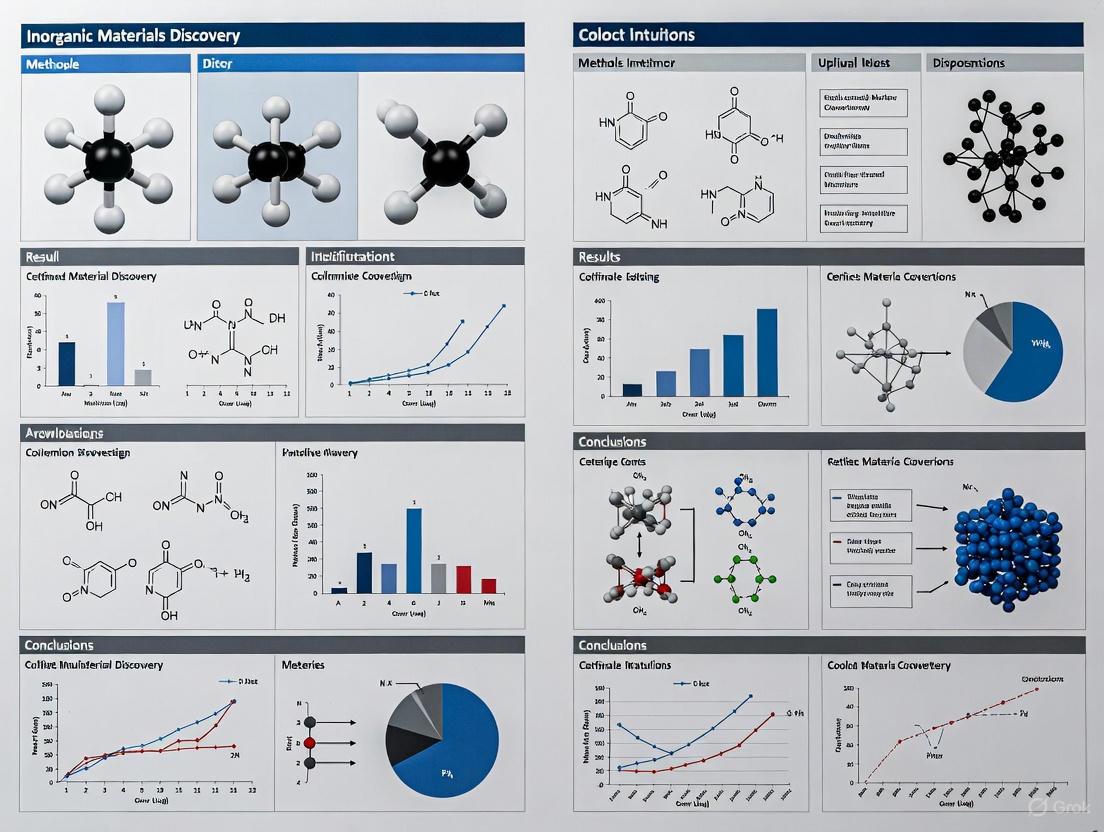

Figure 1: Integrated Workflow for AI-Driven Materials Discovery. This diagram illustrates the closed-loop methodology combining computational prediction with autonomous experimentation, enabling continuous model refinement through experimental feedback.

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Research Reagents and Computational Tools for Materials Discovery

| Tool/Category | Specific Examples | Function in Research | Application Context |

|---|---|---|---|

| Descriptor Calculation Software | RDKit [10], AlvaDesc [3], PaDEL, Mordred [3] | Generates molecular descriptors from chemical structures | Converts structural information into quantitative descriptors for QSPR models |

| Molecular Representations | SMILES [10], InChI [10], Extended Connectivity Fingerprints (ECFPs) [4] | Encodes molecular structures in computer-readable formats | Serves as input for descriptor calculation and machine learning models |

| Specialized Excipients | Miglyol 812 N (MCT) [4] | Lipid-based vehicle for solubility testing and formulation development | Preformulation profiling of drug solubility in lipid-based formulations |

| Characterization Techniques | Powder X-ray diffraction (PXRD) [4], Differential Scanning Calorimetry (DSC) [4] | Solid-state analysis and thermal property characterization | Verification of crystal structure and identification of solid-state changes |

| Machine Learning Frameworks | TXL Fusion [7], Graph Network of Materials Exploration (GNoME) [8] | Integrates chemical heuristics with ML for materials classification | High-throughput screening and discovery of topological materials |

| Autonomous Experimentation | A-Lab [8], Dynamic Flow Reactors [9] | Enables closed-loop optimization without human intervention | Accelerated synthesis and screening of candidate materials |

| PD 0220245 | PD 0220245|IL-8 Receptor Antagonist|Research Chemical | PD 0220245 is a potent, small-molecule interleukin-8 (CXCL8) receptor antagonist for inflammation research. For Research Use Only. Not for human use. | Bench Chemicals |

| Iprauntf2 | Iprauntf2, CAS:951776-24-2, MF:C29H37AuF6N3O4S2, MW:866.71 | Chemical Reagent | Bench Chemicals |

Information-Theoretic Foundations of Chemical Bonding

The transformation of chemical intuition into quantitative frameworks extends to the fundamental understanding of chemical bonding. Information theory (IT) approaches have demonstrated that the key issue in chemistry—an adequate description of chemical bonds in molecular systems—can be successfully addressed using concepts from communication theory [6].

In this framework, the molecular indeterminacy of electron probability distribution relative to input, measured by channel conditional entropy, provides a realistic index of the covalent bond component. The complementary quantity—mutual information between molecular output and promolecular input—represents the amount of information flowing through the molecular channel and generates an adequate representation of the ionic bond component [6]. This IT perspective naturally connects to the Valence-Bond theory of Heitler and London while providing a dichotomous framework for indexing complementary bond components that aligns with chemical intuitive expectations.

The information-theoretic approach reveals intriguing connections between chemical intuition and quantitative descriptors. For example, in benzene, the total bond index is lower than the 3 bits value expected for triple conjugated π-bonds, reflecting the aromaticity of π electrons and their tendency to destabilize the regular hexagonal structure toward a distorted, alternated system—a finding that aligns with modern understanding of σ and π electron influences on aromaticity [6]. This demonstrates how information-theoretic descriptors can capture subtle chemical effects that have traditionally been the domain of expert intuition.

Figure 2: Information-Theoretic Description of Chemical Bonding. This diagram illustrates how information theory quantifies complementary covalent and ionic bond components through entropy and mutual information concepts.

Future Perspectives and Challenges

The integration of chemical intuition with quantitative descriptors faces several important challenges that guide future research directions. A significant issue is the balance between model performance and interpretability—while complex deep learning models often achieve high predictive accuracy, their "black box" nature can limit chemical insights and trust among researchers [3] [8]. This has prompted increased interest in explainable AI approaches that maintain performance while providing mechanistic interpretations.

Another challenge concerns the applicability domains of descriptor-based models. Models trained on specific chemical families may not generalize well to structurally diverse compounds, creating a tension between specialized accuracy and broad applicability [3]. The high chemical diversity common in drug discovery and materials science necessitates customized data preprocessing techniques and careful definition of applicability domains to ensure reliable predictions.

The validation of AI-predicted materials also remains a significant hurdle. As witnessed with DeepMind's GNoME project and Microsoft's MatterGen, controversies have emerged regarding the originality and practicality of AI-generated compounds [8]. Some critics note that predicted materials may contain rare radioactive elements with limited practical value, or in some cases, may represent previously known compounds inadvertently included in training data. These challenges highlight the continued importance of coupling computational prediction with experimental validation in a closed-loop framework.

Despite these challenges, the transformation of chemical intuition into quantitative descriptors continues to accelerate materials discovery. By encoding heuristic knowledge into computable frameworks and combining them with data-driven learning, researchers are creating powerful tools that leverage the strengths of both human expertise and artificial intelligence. As these approaches mature, they promise to overcome current limitations in interpretability and generalizability, ultimately enabling the discovery of advanced functional materials that address critical needs in energy, sustainability, and medicine.

The grand challenge of materials science—the discovery of novel materials with target properties—has traditionally been addressed through a trial-and-error approach driven by human chemical intuition. In this conventional paradigm, experts specify candidate materials based on intuition or incremental modifications of existing materials, then scrutinize their properties experimentally or computationally, repeating this process until reasonable improvements are achieved. This direct design approach is inherently time-consuming, resource-intensive, and significantly bottlenecks efforts to solve future sustainability challenges in a timely manner [11]. However, the field is undergoing a fundamental transformation. Machine-learned inverse design strategies are now greatly accelerating this discovery process by leveraging hidden knowledge obtained from materials data [11]. This paradigm shift moves beyond human intuition to data-driven exploration, enabling researchers to navigate the synthesizable chemical space with unprecedented efficiency and purpose.

Within materials informatics, two distinct mapping directions facilitate this exploration. Forward mapping predicts material properties from structural inputs, while inverse mapping starts with desired properties and identifies materials that satisfy them [11]. This inverse approach forms the core of modern chemical space navigation, relying on two critical components: (1) efficient methods to explore the vast chemical space toward target regions ("exploration"), and (2) fast, accurate methods to predict candidate material properties during this exploration ("evaluation") [11]. The frameworks for this exploration have crystallized into three dominant strategies—high-throughput virtual screening, global optimization, and generative models—each offering distinct methodologies for traversing the chemical universe while ensuring synthesizability, as exemplified by advanced systems like SynFormer, which generates synthetic pathways to guarantee practical tractability [12].

Core Strategies for Inverse Design

High-Throughput Virtual Screening (HTVS)

High-Throughput Virtual Screening represents an extended version of the direct design approach, systematically evaluating materials from existing libraries through an automated, accelerated search [11]. The standard computational HTVS workflow involves three critical phases. First, researchers define the screening scope, which relies heavily on field experts' heuristics; success depends critically on this step, as the scope must contain promising materials without being so extensive that screening becomes computationally prohibitive [11]. Second, first-principles (often Density Functional Theory) or machine learning-based computational screening occurs, typically employing computational funnels where cheaper methods or easier-to-compute properties serve as initial filters, with more sophisticated methods hierarchically narrowing candidate pools [11]. Finally, experimental verification of proposed candidates completes the cycle, with high-throughput experimental methods like sputtering enabling rapid survey of synthesis conditions [11].

Despite its systematic approach, HTVS faces significant limitations. The search remains constrained by the user-selected library (either experimental databases or substituted computational databases), meaning potentially high-performing materials not in the library may be overlooked [11]. Furthermore, since screening proceeds blindly without preferred search directions, efficiency can remain suboptimal [11]. Nevertheless, HTVS has yielded substantial successes. Researchers discovered 21 new Li-solid electrolyte materials by screening 12,831 Li-containing materials in the Materials Project database, while others identified 43 photocatalysts for COâ‚‚ conversion from 68,860 screened materials [11]. To overcome database limitations, techniques like enumerating hypothetical materials through elemental substitution to existing crystals have enabled discoveries of new functional photoanodes and metal nitrides, with data-mined substitution algorithms accelerating experimental discovery rates by factors of two compared to traditional methods [11].

Table 1: Machine Learning Representations for Property Prediction in HTVS

| Representation | Invertibility | Invariance | Model | Application |

|---|---|---|---|---|

| Atomic properties [11] | No | Yes | SVR | Predicting melting temperature, bulk and shear modulus, bandgap |

| Crystal site-based representation [11] | Yes | Yes | KRR | Predicting formation energy of ABC₂D₆ elpasolite structures |

| Average atomic properties [11] | No | Yes | Ensembles of decision trees | Predicting formation energy of inorganic crystal structures |

| Voronoi-tessellation-based representation [11] | No | Yes | Random forest | Predicting formation energy of quaternary Heusler compounds |

| Crystal graph [11] | No | Yes | GCNN | Predicting formation enthalpy of inorganic compounds |

Global Optimization (GO)

Global Optimization approaches address HTVS limitations by performing targeted exploration of chemical space rather than blind screening. Evolutionary Algorithms (EAs), one prominent form of GO, leverage mutations and crossover operations to efficiently visit various local minima by building upon previous configurational visits [11]. This approach generally offers superior efficiency compared to HTVS and can venture beyond the chemical space defined by known materials and their structural motifs [11]. Unlike HTVS, which evaluates fixed database entries, GO methods iteratively propose and evaluate candidates, with each iteration informed by previous results to focus the search on promising regions of chemical space.

The fundamental advantage of Global Optimization lies in its balanced exploration-exploitation dynamic. While HTVS performs pure exploration of a predetermined space, GO algorithms systematically balance exploring new territory with exploiting known promising regions. For inorganic materials discovery, this often involves operating on crystal structure representations that allow for evolutionary operations like mutation (small modifications to atomic positions or substitutions) and crossover (combining elements from promising parent structures). This enables the discovery of completely new materials not present in existing databases, with the geometric landscape of the functionality manifold learned implicitly as iterations progress [11]. The evaluation phase typically employs machine learning models for rapid property prediction, with occasional DFT validation for promising candidates to ensure accuracy.

Generative Models (GM)

Generative Models represent the most recent advancement in inverse materials design, leveraging probabilistic machine learning to generate novel materials from continuous vector spaces learned from prior knowledge of dataset distributions [11]. These models differ fundamentally from both HTVS and GO by learning the underlying distribution of the target functional space during training, either through adversarial learning (implicit) or variational inference (explicit) [11]. The key advantage of GMs is their ability to generate previously unseen materials with target properties residing in the gaps between existing materials by understanding their distribution in continuous space [11].

Recent implementations like SynFormer demonstrate the cutting-edge capabilities of generative approaches by specifically addressing synthesizability concerns that plagued earlier methods. SynFormer introduces a generative modeling framework that produces synthetic pathways for molecules, ensuring designs are synthetically tractable from inception [12]. By incorporating a scalable transformer architecture and diffusion module for building block selection, SynFormer surpasses existing models in synthesizable molecular design [12]. This approach excels in both local chemical space exploration (generating synthesizable analogs of reference molecules) and global chemical space exploration (identifying optimal molecules according to black-box property prediction oracles) [12]. The model's scalability ensures improved performance as computational resources increase, highlighting its potential for applications across drug discovery and materials science [12].

Table 2: Generative Model Representations for Inverse Design

| Representation | Invertibility | Invariance | Model | Application |

|---|---|---|---|---|

| 3D atomic density [11] | Yes | No | VAE | Generation of inorganic crystals |

| 3D atomic density and energy grid shape [11] | Yes | No | GAN | Generation of porous materials |

| Lattice site descriptor [11] | Yes | No | GAN | Generation of graphene/BN-mixed lattice structures |

| Unit cell vectors and coordinates [11] | Yes | No | GAN | Generation of inorganic crystals |

Experimental Protocols & Methodologies

High-Throughput Virtual Screening Protocol

The HTVS protocol for inorganic solid materials begins with database selection and preprocessing, typically sourcing from established repositories like the Materials Project (MP) or Inorganic Crystal Structure Database (ICSD) [11]. For comprehensive screening, researchers often enumerate hypothetical materials through data-mined elemental substitution algorithms, which accelerate experimental discovery rates significantly compared to traditional approaches [11]. The subsequent screening employs a multi-stage computational funnel to balance comprehensiveness with efficiency. Initial filtering uses cheap computational methods or easily computable properties, such as stability proxies or simple compositional descriptors, to rapidly eliminate non-promising candidates [11].

For candidates passing initial filters, more sophisticated property evaluation employs either Density Functional Theory (DFT) calculations or machine learning models. DFT provides high accuracy but demands substantial computational resources, creating bottlenecks when screening large databases [11]. Consequently, ML-aided property prediction has become increasingly integrated into HTVS workflows, particularly for stability evaluation represented by formation energy—a crucial though approximate indicator of synthesizability [11]. Both non-structural descriptor-based models (using composition-weighted averages of atomic properties) and structure-aware models (incorporating radial distribution functions or symmetry-invariant graph representations) have demonstrated strong predictive performance [11]. Successful screening campaigns typically conclude with experimental verification using high-throughput synthesis and characterization techniques, such as sputtering to survey diverse synthesis conditions [11].

Generative Model Implementation

Implementing generative models for chemical space navigation requires careful architectural design and training strategies. Contemporary frameworks like SynFormer employ a multi-component architecture combining a scalable transformer with a diffusion module for building block selection [12]. The training process involves learning the distribution of known synthesizable materials and their synthetic pathways from comprehensive databases, enabling the model to internalize complex relationships between structure, properties, and synthesizability [12].

The generation process typically operates in two distinct modes: local exploration and global exploration. In local chemical space exploration, the model generates synthesizable analogs of reference molecules, maintaining core structural motifs while exploring permissible variations [12]. For global chemical space exploration, the model identifies optimal molecules according to black-box property prediction oracles, venturing into potentially novel structural territories while maintaining synthesizability constraints [12]. Critical to this process is the model's ability to generate synthetic pathways alongside molecular structures, ensuring that proposed materials can be practically realized in the laboratory rather than remaining theoretical constructs [12]. The performance of these models demonstrates positive scaling relationships with computational resources, suggesting continued improvement as computational capabilities advance [12].

Visualizing the Inverse Design Workflow

The following diagram illustrates the core logical relationships and workflows in modern inverse design strategies for navigating chemical spaces:

Diagram 1: Inverse Design Workflow for Chemical Space Navigation (76 characters)

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Computational Tools for Chemical Space Navigation

| Tool/Resource | Type | Function | Application Context |

|---|---|---|---|

| Materials Project (MP) [11] | Database | Provides calculated properties of known and predicted inorganic crystals | HTVS screening scope definition; training data for ML models |

| Inorganic Crystal Structure Database (ICSD) [11] | Database | Repository of experimentally determined inorganic crystal structures | HTVS screening; generative model training data |

| Density Functional Theory (DFT) [11] | Computational Method | First-principles calculation of electronic structure and properties | High-fidelity property evaluation in HTVS; validation for ML predictions |

| Crystal Graph Convolutional Neural Network (CGCNN) [11] | Machine Learning Model | Symmetry-invariant neural network for periodic crystal structures | Fast property prediction (formation energies, band gaps) in HTVS and GO |

| Evolutionary Algorithms (EAs) [11] | Optimization Method | Global optimization through mutation and crossover operations | Navigating chemical space beyond known materials in GO approaches |

| SynFormer [12] | Generative Model | Transformer-based framework for synthesizable molecular design | Generating synthetic pathways and ensuring synthesizability in GM |

| Matplotlib [13] | Visualization Library | Python plotting library with scientific colormaps | Data visualization and result presentation |

| Color Brewer [13] | Color Tool | Web tool for selecting contrasting color maps | Creating accessible visualizations for scientific publications |

| Cannabisin H | Erythro-canabisine H (Cannabisin H)|CAS 403647-08-5 | Erythro-canabisine H is a high-purity lignanamide for research. Explore its potential biological activities. This product is for research use only (RUO). Not for human or veterinary use. | Bench Chemicals |

| Phosphine, pentyl- | Phosphine, pentyl-, CAS:10038-55-8, MF:C5H13P, MW:104.13 g/mol | Chemical Reagent | Bench Chemicals |

The navigation of vast chemical spaces has evolved dramatically from trial-and-error approaches rooted in human chemical intuition to sophisticated, data-driven inverse design strategies. The three principal methodologies—high-throughput virtual screening, global optimization, and generative models—each offer complementary strengths for addressing different aspects of the materials discovery challenge. HTVS provides systematic evaluation of known chemical spaces, GO enables efficient optimization beyond existing databases, and generative models like SynFormer offer the most promising path toward truly novel materials discovery by learning underlying distributions and ensuring synthesizability through pathway generation [11] [12]. As these computational approaches continue to mature and integrate more deeply with high-throughput experimental validation, they promise to significantly accelerate the design of next-generation materials for energy, sustainability, and healthcare applications, ultimately transforming how we navigate the virtually infinite possibilities of chemical space.

The discovery of quantum materials, characterized by exotic electronic, magnetic, and topological properties, has traditionally relied on a foundation of chemical intuition—heuristics and rules of thumb developed through decades of experimental observation. Among these, the tolerance factor, a geometric parameter originally developed for perovskite structures, has experienced a renaissance in guiding the design of complex quantum materials, particularly those with square-net geometries. These layered materials, often hosting Dirac semimetals, topological insulators, and unconventional superconductors, present a unique challenge and opportunity for materials design. This case study examines how classical chemical intuition, embodied by the tolerance factor, integrates with modern autonomous AI-driven discovery frameworks like SparksMatter [14] and generative models such as MatterGen [15]. This synergy is creating a new paradigm for inorganic materials research, where physics-aware AI agents leverage fundamental chemical principles to navigate vast compositional spaces and propose novel, stable quantum materials with targeted properties. By framing this integration within a broader thesis on chemical intuition, we explore how multi-agent AI systems do not replace traditional understanding but rather augment it, enabling the systematic exploration and validation of hypotheses across scales previously inaccessible to human researchers alone.

Theoretical Foundation: The Tolerance Factor in Square-Net Chemistry

Geometric Origins and Adaptation

The tolerance factor (t) was originally formulated by Goldschmidt in the 1920s to predict the stability of perovskite structures (ABX₃) based on ionic radii:

[ t = \frac{rA + rX}{\sqrt{2}(rB + rX)} ]

where (rA), (rB), and (r_X) represent the ionic radii of the constituent ions. For stable perovskite formation, t typically must lie between 0.8 and 1.0. In the context of square-net materials, this concept has been adapted for layered structures where sheets of atoms form planar, square-grid configurations, often found in materials such as the ZrSiS-type structure family. These square-net layers are typically composed of main-group or transition metal elements, separated by spacer layers whose geometric compatibility is crucial for stability.

In square-net systems, the tolerance factor is modified to account for the different dimensional constraints of the layered structure, often considering the ratio of the spacer layer thickness to the ideal square-net layer separation. This adapted parameter helps predict structural distortions, phase transitions, and the stability of the desired quantum phase. Materials with tolerance factors close to the ideal value (often ~1.0 for square-net systems) tend to form the desired structure without distortion, enabling the emergence of topological electronic states and other quantum phenomena.

Quantum Phenomena in Square-Net Materials

Square-net materials host extraordinary quantum properties that make them attractive for both fundamental research and technological applications:

- Dirac and Weyl semimetal phases: Materials such as Cd₃As₂ and ZrSiS exhibit linear band crossings in their electronic structure, leading to ultra-high mobility charge carriers and unusual magnetotransport properties [16].

- Topological insulating states: Certain square-net compounds host robust surface states protected by time-reversal symmetry, of interest for spintronics and quantum computing.

- Exotic magnetism and superconductivity: The layered nature and geometric frustration in square-net lattices can lead to unconventional magnetic ground states and superconducting pairing mechanisms.

The stability of these quantum phases is exquisitely sensitive to structural perfection, which is precisely where the tolerance factor provides essential guidance for materials design and selection.

Computational and AI-Driven Methodologies

Autonomous Discovery Frameworks

The SparksMatter framework represents a paradigm shift in quantum materials discovery through its multi-agent, physics-aware reasoning architecture [14]. As illustrated below, this system automates the entire research cycle from ideation to final reporting, specifically designed to incorporate physical constraints like the tolerance factor during materials generation and selection.

Figure 1: The autonomous research workflow implemented by the SparksMatter framework, showing the iterative cycle from query to final report with continuous refinement [14].

Specialized AI agents within SparksMatter perform distinct functions:

- Scientist agents interpret user queries regarding square-net material design, define tolerance factor constraints, and frame the scientific context for quantum material discovery.

- Planner agents translate high-level strategies into executable plans specifying tool invocations for structure generation, property prediction, and stability assessment.

- Assistant agents execute the plans by generating code, interfacing with materials databases (Materials Project, OQMD) [17], and running simulations.

- Critic agents review outputs, identify research gaps, and suggest follow-up validation through density functional theory (DFT) calculations or experimental synthesis.

Generative Models for Inverse Design

MatterGen represents a complementary approach specifically designed for inverse materials design [15]. This diffusion-based generative model creates stable, diverse inorganic materials across the periodic table and can be fine-tuned to steer generation toward specific property constraints. For square-net quantum materials, MatterGen can be conditioned on:

- Chemical composition constraints to explore specific element combinations

- Symmetry requirements to maintain the square-net crystal structure

- Electronic properties such as band gap, carrier density, or magnetic moment

- Stability metrics including formation energy and phase stability

The model employs a customized diffusion process that generates crystal structures by gradually refining atom types, coordinates, and the periodic lattice while respecting physical constraints and symmetry requirements. After generation, proposed structures undergo DFT validation to assess stability and property prediction.

Quantum Computational Approaches

For accurate simulation of square-net quantum materials, hybrid quantum-classical algorithms are emerging to address the limitations of classical computational methods for strongly correlated electron systems [18]. The isometric tensor network state (isoTNS) approach provides a natural framework for representing 2D quantum systems and can be optimized using quantum computers to circumvent the exponential complexity faced by classical techniques. This is particularly valuable for square-net materials near quantum critical points or with significant electron correlations, where standard mean-field approaches may fail.

Experimental Protocols and Validation

Computational Screening Workflow

The integration of tolerance factor analysis with AI-driven materials discovery follows a structured computational workflow for designing and validating novel square-net materials:

Figure 2: Integrated computational-experimental workflow for square-net quantum material discovery, combining traditional chemical intuition with AI-driven methods.

Stability and Property Validation

AI-proposed square-net materials must undergo rigorous validation to assess their viability:

Stability Metrics:

- Formation energy from DFT calculations relative to elemental phases

- Energy above convex hull (≤ 0.1 eV/atom for stability) [15]

- Phonon dispersion calculations to confirm dynamic stability

- Molecular dynamics simulations to assess thermal stability

Property Validation:

- Electronic structure including band gap, band topology, and Fermi surface

- Magnetic properties including moment alignment and coupling

- Transport properties such as conductivity and carrier mobility

Table 1: Key Validation Metrics for Proposed Square-Net Quantum Materials

| Validation Type | Calculation Method | Target Threshold | Relevance to Square-Net Materials |

|---|---|---|---|

| Thermodynamic Stability | DFT Formation Energy | ≤ 0.1 eV/atom above hull [15] | Ensures synthesizability |

| Dynamic Stability | Phonon Dispersion | No imaginary frequencies | Confirms lattice stability |

| Electronic Structure | DFT Band Structure | Non-trivial topology indicators | Confirms quantum properties |

| Tolerance Factor | Geometric Analysis | 0.9-1.1 (system dependent) | Predicts structural stability |

The modern quantum materials researcher utilizes an integrated suite of computational and experimental resources. The table below details essential "research reagents" in this context—key databases, software tools, and AI models that enable the discovery and characterization of square-net materials.

Table 2: Essential Research Resources for Square-Net Quantum Materials Discovery

| Resource Name | Type | Function in Research | Relevance to Tolerance Factor & Square-Nets |

|---|---|---|---|

| SparksMatter [14] | Multi-Agent AI Framework | Autonomous materials design workflow execution | Integrates tolerance factor as constraint in agent reasoning |

| MatterGen [15] | Generative Diffusion Model | Inverse design of stable inorganic materials | Generates novel square-net structures conditioned on properties |

| Materials Project [14] [17] | Computational Database | Repository of DFT-calculated material properties | Provides reference structures and formation energies |

| OQMD [17] | Computational Database | Open Quantum Materials Database | Additional source for stability assessment |

| DFT Software (VASP, Quantum ESPRESSO) | Simulation Tool | First-principles property calculation | Validates stability and electronic structure of proposed materials |

| Ionic Radii Databases | Reference Data | Source of ionic radii for tolerance factor calculation | Enables geometric analysis of candidate structures |

Data Presentation and Analysis

Performance Metrics for AI-Generated Materials

Rigorous benchmarking of AI-generated quantum materials against traditional discovery methods reveals significant advantages in efficiency and success rate. The following table summarizes quantitative performance data for the MatterGen model compared to previous approaches:

Table 3: Performance Comparison of Generative Models for Materials Design [15]

| Generative Model | Stable, Unique & New (SUN) Materials | Average RMSD to DFT Relaxed (Ã…) | Success Rate for Target Properties | Diversity Retention at Scale |

|---|---|---|---|---|

| MatterGen | 75% below 0.1 eV/atom above hull [15] | < 0.076 Å [15] | > 2× baseline for multiple constraints [15] | 52% unique after 10M generations [15] |

| CDVAE | ~30% below 0.1 eV/atom above hull | ~0.8 Ã… | Limited to formation energy optimization | Rapid saturation |

| DiffCSP | ~35% below 0.1 eV/atom above hull | ~0.7 Ã… | Limited property conditioning | Moderate diversity |

| Substitution Methods | Varies by system (< 40% typically) | N/A (existing structures) | Limited to similar chemistries | Limited by known crystals |

| Random Structure Search | < 5% for complex systems | Often large (> 1.0 Ã…) | Poor for targeted design | High but mostly unstable |

The dramatically reduced RMSD (root-mean-square deviation) for MatterGen-generated structures—less than 0.076 Å compared to DFT-relaxed structures—indicates that the AI-proposed materials are very close to their local energy minimum, requiring minimal relaxation to reach stable configurations [15]. This is particularly valuable for square-net materials, where small structural distortions can significantly alter quantum properties.

Tolerance Factor Ranges for Square-Net Stability

The application of tolerance factor analysis to square-net materials reveals system-specific optimal ranges that guide compositional selection:

Table 4: Tolerance Factor Ranges for Stable Square-Net Material Families

| Material Family | Crystal Structure | Ideal Tolerance Factor Range | Key Quantum Phenomena | Representative Compounds |

|---|---|---|---|---|

| ZrSiS-type | Layered tetragonal | 0.95-1.05 | Dirac semimetals, topological insulators | ZrSiS, HfGeAs, CeSbTe |

| PbO-type | Layered tetragonal | 0.9-1.0 | Topological crystalline insulators | PbO, SnSe |

| FeSe-type | Layered tetragonal | 0.85-0.95 | Unconventional superconductivity | FeSe, FeS, FeTe |

| Bi2O2S-type | Layered tetragonal | 0.95-1.05 | Air-stable Dirac semimetals | Bi2O2Se, Bi2O2Te |

Materials falling within these optimal tolerance factor ranges demonstrate higher stability and are more likely to exhibit the desired quantum phenomena due to reduced structural distortions that might otherwise perturb the electronic structure.

Discussion: The Evolving Role of Chemical Intuition

The integration of geometric parameters like the tolerance factor with autonomous AI systems represents a powerful synthesis of traditional chemical intuition and modern computational intelligence. This hybrid approach addresses fundamental challenges in quantum materials discovery:

- Navigating vast compositional spaces: While AI can efficiently explore millions of potential compositions, tolerance factor analysis provides a physically meaningful constraint that focuses the search on chemically plausible regions.

- Balancing novelty and stability: Generative models like MatterGen propose truly novel structures, while tolerance factor screening increases the probability that these structures will be synthetically accessible.

- Multi-property optimization: Square-net quantum materials often require simultaneous optimization of multiple properties—structural stability, electronic band topology, magnetic response—which AI systems can handle through conditioned generation and iterative refinement.

The SparksMatter framework exemplifies how multi-agent reasoning captures the essence of scientific thinking, with different "expert" agents specializing in various aspects of the design problem, much like a collaborative research team [14]. This architecture enables the formalization and scaling of chemical intuition, transforming heuristic knowledge into executable design rules within an autonomous discovery pipeline.

This case study demonstrates that the tolerance factor, a classic tool of chemical intuition, remains highly relevant in the age of AI-driven materials discovery. When integrated with autonomous frameworks like SparksMatter and generative models like MatterGen, it provides a physical constraint that guides the exploration of quantum materials with square-net geometries. This synergy enables more efficient navigation of complex compositional spaces while maintaining connection to fundamental chemical principles that govern material stability and properties.

Looking forward, the continued development of physics-aware AI agents [14], quantum-enhanced tensor network methods [18], and foundational generative models [15] promises to further accelerate the discovery of quantum materials with tailored properties. As these technologies mature, we anticipate a new era of materials design where AI systems not only propose candidates but also actively learn and refine chemical intuition, potentially discovering new design principles beyond human recognition. For square-net quantum materials specifically, this integrated approach offers a pathway to systematically engineer Dirac points, topological surface states, and correlated electron phenomena through targeted structural and compositional control—ultimately enabling technologies from low-power electronics to fault-tolerant quantum computation.

The fusion of artificial intelligence (AI) and material science promises to revolutionize how we discover new materials, offering a future where novel compounds for carbon capture or advanced battery storage can be designed before even stepping into a laboratory [19]. This data-driven approach leverages machine learning models, including Graph Neural Networks (GNNs) and Physics-Informed Neural Networks (PINNs), to predict material properties at the atomic level, dramatically accelerating a process that has traditionally been slow and resource-intensive [19]. The ambitious targets of initiatives like the Materials Genome Initiative, which seeks to reduce the average 20-year "molecule-to-market" lead time by up to fourfold, are now within realistic reach thanks to these technological advances [20].

However, this rapid progress faces a significant obstacle: the data bottleneck. Despite the proliferation of AI tools, access to unique, high-quality datasets remains a substantial hurdle [19]. Material science datasets are often vast and diverse, containing millions of molecular structures, quantum properties, and thermodynamic behaviors, yet they are frequently proprietary, scarce, or inconsistent [19]. This limitation is compounded by the fact that scientific data, in contrast to the abundant web data used to train many large language models, is often limited and requires strong inductive biases to compensate [19]. Within this context, the role of chemical intuition—the tacit knowledge and experiential understanding of seasoned researchers—becomes not merely complementary but essential to guiding AI, interpreting its outputs, and ensuring that discoveries are both novel and practical.

Quantitative Landscape: The Data Challenge in Focus

The data bottleneck in materials discovery is not merely a theoretical concern but a quantifiable barrier. The following table summarizes the core quantitative challenges and the computational demands of AI-driven materials science.

Table 1: Quantitative Overview of Data and Computational Challenges

| Challenge Area | Specific Data Issue | Quantitative Impact & Requirements |

|---|---|---|

| Data Scarcity | Lack of exclusive, high-quality datasets [19] | Difficult for startups to differentiate without unique data; limits model accuracy. |

| Data Generation | Pace of experimental data generation [19] [9] | Traditional methods are slow; Dynamic Flow Experiments can improve data acquisition efficiency by an order-of-magnitude [9]. |

| Computational Cost | High-Performance Computing (HPC) needs [19] | Requires powerful hardware (GPUs, supercomputers); GPU costs dropped 75% in the past year, making scaling more affordable [19]. |

| Model Validation | Overestimation of material capabilities [8] | Errors in underlying training databases can lead to incorrect predictions (e.g., overestimation of COâ‚‚ binding in MOFs) [8]. |

The computational burden of overcoming these data challenges is significant. The optimization of materials involves solving problems in a high-dimensional space through advanced simulation techniques like quantum simulations and Density Functional Theory (DFT), which demand substantial resources [19]. While the recent drop in GPU costs is a positive development, the fundamental issue remains: the effectiveness of any AI model is intrinsically tied to the quality, quantity, and exclusivity of the data it is trained on [19].

The Limits of AI: Case Studies and the Originality Debate

Despite high-profile successes, AI-driven materials discovery has faced scrutiny regarding the practicality and originality of its findings. The case of Microsoft's MatterGen is illustrative. While designed to generate new inorganic materials from scratch to meet specific design criteria, it reportedly synthesized a disordered compound known as "tantalum chromium oxide," which a preprint paper indicated had been first prepared as early as 1972 and was even included in the model's own training data [8]. This highlights a critical vulnerability: AI models can "rediscover" known materials, raising questions about the true novelty of their outputs.

Similarly, projects like the Metaverse platform's collaboration with Georgia Institute of Technology have faced validation challenges. Their AI predicted over 100 new metal-organic frameworks (MOFs) for carbon dioxide adsorption. However, independent computational analysis confirmed that these proposed materials were incapable of direct air capture, as the model had overestimated the material's ability to bind CO₂—a error partly attributed to inaccuracies in the underlying database used for training [8]. These cases underscore that AI predictions are only as reliable as the data they are built upon and must be subjected to rigorous verification, often requiring the expert judgment of human scientists to identify such shortcomings.

Furthermore, a review of DeepMind's GNoME project revealed that over 18,000 of its predicted compounds contained rare radioactive elements, such as promethium and actinium, leading to legitimate questions about their practical value and synthesizability on a meaningful scale [8]. While a DeepMind spokesperson noted that over 700 GNoME-predicted compounds have been independently synthesized, the debate highlights a key disconnect between statistical prediction and practical application [8]. This is where chemical intuition is paramount, guiding the selection of AI-generated candidates that are not only stable in silico but also synthesizable, scalable, and economically viable for real-world applications.

Experimental Protocols: Bridging Computation and Validation

For AI-predicted materials to transition from digital candidates to physical realities, robust experimental validation is essential. The following workflow diagram outlines the key stages in the "design-to-device" pipeline for data-driven materials discovery.

Diagram 1: The Design-to-Device Pipeline for Data-Driven Materials Discovery [20].

Protocol for Autonomous Discovery and Validation

The closed-loop experimentation, as implemented in systems like the A-Lab at Lawrence Berkeley National Laboratory, follows a detailed protocol [8]:

- Step 1: Candidate Selection. AI systems like GNoME or MatterGen first identify or generate candidate materials with desired properties from vast chemical spaces [19] [8]. The A-Lab, for instance, synthesizes compounds whose structures were predicted by DFT but never before prepared [8].

- Step 2: Robotic Synthesis. The AI controls robotic systems to perform the synthesis. For example, the A-Lab uses robotic arms to weigh and mix solid powders, which are then heated in furnaces [8].

- Step 3: In-situ Analysis. The synthesized product is automatically transferred to a diffractometer for analysis. The system analyzes whether the X-ray diffraction pattern of the product matches the predicted crystal structure of the target material [8].

- Step 4: Decision and Iteration. If the product does not meet the target specifications, the AI system analyzes the result, adjusts the synthesis formula or conditions (e.g., precursor amounts, heating temperature, or time), and initiates another synthesis cycle. This creates an autonomous feedback loop for optimization [8].

Adhering to established guidelines for reporting experimental protocols is crucial for reproducibility. This includes detailing all necessary information for obtaining consistent results, such as specific catalog numbers for reagents, exact experimental parameters (e.g., temperature in °C, precise timing), and unambiguous descriptions of procedures [21]. A comprehensive protocol should fundamentally include details on the sample, instruments, reagents, workflow, parameters, and troubleshooting hints [21].

The experimental workflow in modern materials discovery relies on a combination of computational, physical, and data resources. The following table details key components of the researcher's toolkit.

Table 2: Essential Research Reagent Solutions for AI-Driven Materials Discovery

| Tool/Resource Category | Specific Example | Function & Application |

|---|---|---|

| Computational AI Models | DeepMind's GNoME [19] [8] | Uses Graph Neural Networks (GNNs) to discover new stable crystalline materials by modeling atomic-level structures. |

| Computational AI Models | Microsoft's MatterGen [19] [8] | A generative AI model designed to create new inorganic materials from scratch based on specified design criteria. |

| Validation & Simulation AI | Microsoft's MatterSim [8] | An auxiliary AI system that verifies the stability of AI-proposed material structures under real-world temperature and pressure conditions. |

| Physical Robotics | A-Lab (Lawrence Berkeley Natl. Lab) [8] | An automated robotic system that synthesizes predicted inorganic compounds, analyzes the products, and refines recipes autonomously. |

| Data Intensification | Dynamic Flow Experiments [9] | A microfluidic strategy that continuously maps transient reaction conditions to steady-state equivalents, drastically improving data throughput for material synthesis. |

| Data & Resource Portals | Resource Identification Portal (RIP) [21] | A portal that helps researchers find unique identifiers for key biological resources like antibodies, cell lines, and software, ensuring accurate reporting. |

| Specialized Databases | Addgene [21] | A web-application repository that allows researchers to uniquely identify and share plasmids. |

This toolkit enables a modern, integrated research paradigm. For instance, a discovery might begin with a generative model like MatterGen, have its stability verified by MatterSim, be synthesized and optimized by an A-Lab-like system, and have all its constituent resources properly identified via portals like RIP to ensure the experiment can be replicated [21] [8].

Integrating Intuition with AI: A Synergistic Workflow

The most effective path forward leverages the strengths of both artificial intelligence and human expertise. The following diagram illustrates this integrated, closed-loop workflow.

Diagram 2: The Integrated Human-AI Discovery Workflow.

This synergistic workflow creates a powerful active learning cycle. It begins and ends with human expertise: researchers frame the problem based on scientific needs and practical constraints, setting the goals for the AI [19]. The AI then performs its core strength—rapidly screening millions of possibilities and identifying promising candidates that a human might never consider [19]. These candidates are funneled into automated validation systems, which generate high-quality, structured data. This is where tools like Dynamic Flow Experiments are transformative, acting as a "data intensification" strategy that yields at least an order-of-magnitude improvement in data acquisition efficiency compared to state-of-the-art self-driving fluidic laboratories [9]. The resulting data is then interpreted by human scientists, who assess the practical viability, potential for scale-up, and true novelty of the findings, using their chemical intuition to spot errors or over-optimistic predictions made by the AI [8]. Finally, this interpreted knowledge is used to refine the AI models and the problem itself, creating a virtuous cycle of improvement. This end-to-end integration, combining Physics AI (simulation) with Physical AI (robotic experimentation), is the herculean but necessary task that bridges the gap between theoretical innovation and real-world application [19].

The data bottleneck in materials discovery is a persistent reality, stemming from the scarcity of high-quality data, the computational cost of generating it, and the propensity of AI models to produce results that are either non-original or non-practical. While technological advances like data intensification strategies and dropping computational costs are helping to widen this bottleneck, they alone are not a panacea.

The path to accelerated discovery does not lie in replacing human intuition with AI but in forging a deeper collaboration between the two. The chemist's intuition—forged through years of experience and a deep understanding of chemical principles—remains essential for framing meaningful research questions, interpreting AI outputs with skepticism and context, and guiding the exploration toward materials that are not just computationally stable but also synthesizable, scalable, and relevant to societal needs. By integrating human expertise directly into the "design-to-device" pipeline, the materials science community can harness the full potential of data-driven discovery while navigating the inherent limitations of the data itself, ultimately accelerating the journey from the lab to transformative real-world applications.

Frameworks for Capturing Insight: From ME-AI to Multi-Agent Systems

The discovery and development of new inorganic materials and drug molecules are processes deeply reliant on the specialized knowledge and intuitive judgment of expert scientists. This "chemical intuition" is a culmination of years of experience, yet it is often subjective and difficult to scale or transfer. The Model-Expert Artificial Intelligence (ME-AI) Framework addresses this challenge by providing a systematic methodology for distilling this expert knowledge into machine learning models. This technical guide details the core principles, experimental protocols, and applications of the ME-AI framework within chemical and materials discovery research, transforming subjective expertise into scalable, quantifiable computational proxies.

Core Principles of the ME-AI Framework

The ME-AI Framework is built on two foundational pillars: the formalization of expert knowledge and the use of preference learning to model nuanced decision-making.

Formalizing Expert Knowledge

A critical first step is moving from unstructured expert opinion to a structured, machine-readable format. The Sample-Instrument-Reagent-Objective (SIRO) model provides a minimal information framework for representing experimental protocols, akin to the PICO model in evidence-based medicine [22]. It captures the essential entities involved in an experiment:

- Sample: The material or biological specimen under investigation.

- Instrument: The equipment used to perform the experiment.

- Reagent: The chemicals and substances used.

- Objective: The goal or desired outcome of the protocol.

This structured representation allows for the semantic modeling of protocols, making them searchable and analyzable, and forms the basis for encoding domain knowledge [22].

Preference Learning as a Proxy for Intuition

Directly quantifying a scientist's intuition is challenging. The ME-AI framework instead uses pairwise comparison as a more robust alternative to absolute scoring [23]. In this setup, experts are presented with two candidate molecules or materials and are asked to select the one they prefer based on their intuition for the property of interest (e.g., drug-likeness, synthesizability). This approach mitigates cognitive biases like the "anchoring effect" that can plague Likert-scale ratings [23]. The collected data, comprising thousands of such preferences, is used to train a model to learn an implicit scoring function that reflects the collective expert intuition.

Quantitative Data Collection & Performance

A Novartis case study exemplifies the data collection and model training process. Over several months, 35 chemists provided over 5,000 pairwise annotations on molecules [23]. The inter-rater agreement, measured by Fleiss' κ, was moderate (0.32-0.4), indicating a consistent but personal-driven signal, while intra-rater agreement, measured by Cohen's κ, was higher (0.59-0.6), showing individual consistency [23].

Table 1: Quantitative Performance of a Preference Learning Model for Chemical Intuition [23]

| Training Data (Number of Pairs) | Predictive Performance (AUROC) | Evaluation Method |

|---|---|---|

| Initial Batch | ~0.60 | 5-Fold Cross-Validation |

| 1,000 Pairs | ~0.74 | 5-Fold Cross-Validation |

| 5,000 Pairs | >0.74 | 5-Fold Cross-Validation |

| N/A | ~0.75 | Validation on Preliminary Round Data |

The model's performance, measured by the Area Under the Receiver Operating Characteristic curve (AUROC), showed steady improvement with more data, indicating successful learning of the underlying preference structure [23]. Analysis showed the learned scoring function was orthogonal to many standard cheminformatics descriptors, capturing a unique aspect of chemical intuition [23].

Table 2: Correlation of Learned Scoring Function with Standard Cheminformatics Descriptors [23]

| Cheminformatics Descriptor | Approximate Pearson Correlation (r) with Learned Score | ||

|---|---|---|---|

| QED (Quantitative Estimate of Drug-likeness) | < | 0.4 | |

| Fingerprint Density | < | 0.4 | |

| Fraction of Allylic Oxidation Sites | < | 0.4 | |

| Synthetic Accessibility (SA) Score | Slight Positive Correlation | ||

| SMR VSA3 (Surface Area for specific Molar Refractivity) | Slight Negative Correlation |

Experimental Protocols for ME-AI Implementation

Implementing the ME-AI framework requires a rigorous methodology for data collection, modeling, and validation.

This protocol outlines the steps for gathering pairwise comparison data from domain experts.

- Candidate Set Generation: Compile a diverse set of candidate molecules or materials relevant to the research domain (e.g., from existing corporate libraries or public databases).

- Pairwise Comparison Design: Actively generate pairs of candidates for evaluation. An active learning strategy is recommended, where the model in training selects the most informative pairs for experts to label next, optimizing the data collection efficiency [23].

- Annotation Interface & Deployment: Develop a simple, user-friendly interface that presents two structures and records the expert's preference. Deploy this to a panel of expert scientists (e.g., medicinal chemists for drug discovery).

- Data Collection and Quality Control: Run the data collection campaign over multiple rounds. Incorporate redundant pairs to measure intra-rater consistency and filter out unreliable annotators [23].

Protocol for Training and Validating the Preference Model

This protocol details the computational workflow for creating the ME-AI model.

- Molecular Representation: Convert each candidate into a numerical representation. Common choices include molecular fingerprints, graph neural networks, or descriptor vectors [23].

- Model Selection & Training: Employ a learning-to-rank algorithm or a simple neural network. The model is trained to predict the probability that an expert will prefer one candidate over another in a given pair.

- Validation: Validate model performance using cross-validation and hold-out test sets. Performance is measured by the AUROC, where 0.5 represents random guessing and 1.0 represents perfect prediction [23].

- Deployment and Application: The trained model can be deployed as a scoring function for:

ME-AI Framework Workflow

Application in Chemical Intuition & Materials Discovery

The ME-AI framework finds powerful applications in capturing and scaling chemical intuition.

Extracting Medicinal Chemistry Intuition

In drug discovery, the framework has been successfully used to replicate the lead optimization decisions of medicinal chemists. The learned scoring function captured aspects of desirability not fully explained by standard metrics like QED or synthetic accessibility, effectively "bottling" the nuanced preferences of a team of chemists [23]. This proxy can then be used to automatically rank compounds or steer generative models toward novel, drug-like chemical space.

Emergent Chemical Intuition in Machine Learning Interatomic Potentials

Beyond expert preferences, the ME-AI philosophy extends to models that learn "intuition" directly from physical data. Universal Machine Learning Interatomic Potentials are a key example. These models are trained on quantum mechanical data to predict the potential energy of atomistic systems [24].

Research shows that at sufficient scale, these models can exhibit emergent abilities, such as spontaneously learning to decompose the total energy of a system into physically meaningful local representations without explicit supervision [24]. For instance, an Allegro model trained on the SPICE dataset learned representations that quantitatively agreed with literature values for Bond Dissociation Energies (BDEs) [24]. This represents a form of machine-learned chemical intuition for reactivity.

However, a scaling disparity is observed: while reaction energy (ΔE) prediction improves consistently with more data and larger models, activation barrier (E_a) prediction often hits a "scaling wall" [24]. This indicates that predicting kinetics is a fundamentally harder task for the model, providing crucial insight for future MLIP development.

Emergent Chemical Intuition in MLIPs

The Scientist's Toolkit: Research Reagent Solutions

The following table details key computational and data resources used in implementing the ME-AI framework.

Table 3: Essential Research Reagents & Resources for ME-AI Experiments

| Resource Name | Type | Function in ME-AI Workflow |

|---|---|---|

| RDKit [23] | Cheminformatics Software | Provides routines for computing molecular descriptors, fingerprints, and handling chemical data. |

| SPICE Dataset [24] | Molecular Dataset | A large, diverse dataset of quantum mechanical calculations used for training universal ML Interatomic Potentials. |

| SMART Protocols Ontology (SP) [22] | Ontology | Facilitates the semantic representation of experimental protocols, enabling structured knowledge formalization. |

| MolSkill [23] | Software Package | Production-ready models and code for molecular preference learning, provided under a permissive open-source license. |

| Allegro [24] | E(3)-Equivariant Neural Network | A state-of-the-art architecture for building ML Interatomic Potentials capable of learning emergent chemical properties. |

| Boc-Ser-OH.DCHA | Boc-Ser-OH.DCHA, CAS:10342-06-0, MF:C20H38N2O5, MW:386.5 g/mol | Chemical Reagent |

| 2,3-Diphenylpyridine | 2,3-Diphenylpyridine, CAS:33421-53-3, MF:C17H13N, MW:231.29 g/mol | Chemical Reagent |

The discovery and development of novel inorganic materials have traditionally been guided by chemical intuition, a skill honed through years of experimental experience. However, this intuition-driven approach often relies on positive results, overlooking the wealth of information hidden in unsuccessful experiments. This "dark data"—comprising failed reactions, suboptimal conditions, and characterized intermediates—remains largely untapped, locked in laboratory notebooks and unstructured reports. Machine learning (ML) is now revolutionizing this domain by extracting actionable insights from these historical failures, transforming subjective intuition into a quantifiable, data-driven framework. This whitepaper details methodologies for systematically leveraging dark data to accelerate inorganic materials discovery, providing technical protocols and computational frameworks to integrate this approach into modern research workflows.

The Critical Role of Dark Data in Materials Science

In diversified chemistry R&D, it is estimated that 55 percent of data stored by organizations is dark data—unstructured or semi-structured information not easily searchable or accessible [25]. This data, derived from lab notebooks, LIMS, experimental reports, and literature, remains a largely untapped asset. Around 90 percent of global business and IT executives agree that extracting value from unstructured data is essential for future success [25].

For inorganic materials synthesis, the traditional discovery cycle relying on trial-and-error often takes months or even years due to the multitude of adjustable parameters and hard-to-control variables [26]. Unlike organic synthesis, where mechanisms are better understood, inorganic solid-state synthesis mechanisms remain unclear, lacking universal theory on phase evolution during heating [26]. This knowledge gap makes the systematic utilization of all experimental data, especially failures, particularly valuable.

Table: Characteristics of Dark Data in Chemical R&D

| Data Type | Common Sources | Primary Challenges | Potential Value |

|---|---|---|---|

| Historical Experimental Data | Lab notebooks, LIMS | Scattered, incomplete, unstructured | Insights for current/future projects |

| External Data | Academic papers, patents, reports | Difficult to access and integrate | New innovation opportunities |

| Unstructured Data | Scientific articles, lab notes | Requires specialized analysis tools | Hidden patterns and relationships |

Machine Learning Frameworks for Extracting Value from Failed Experiments

Foundational Case Study: Predicting Crystallization of Vanadium Selenites

A landmark study demonstrated how machine learning trained on failed experiments can dramatically predict successful synthesis conditions. Researchers used information on 'dark' reactions—failed or unsuccessful hydrothermal syntheses—collected from archived laboratory notebooks, applying cheminformatics techniques to add physicochemical property descriptors to the raw notebook information [27] [28].

When tested with previously untested organic building blocks, the machine learning model outperformed traditional human strategies, successfully predicting conditions for new organically templated inorganic product formation with a 89 percent success rate [27] [28]. By inverting the ML model, researchers could extract new hypotheses regarding the conditions for successful product formation, demonstrating how failure-driven models can advance fundamental understanding [27].

Advanced Framework: Virtual Screening with Deep Learning

Later work addressed the dual challenges of data sparsity and data scarcity in inorganic synthesis by implementing a variational autoencoder (VAE) to compress sparse synthesis representations into lower-dimensional spaces [29]. This approach enabled screening of synthesis parameters for materials like SrTiO₃ and identified driving factors for brookite TiO₂ formation and MnO₂ polymorph selection [29].

To overcome data scarcity, researchers devised a novel data augmentation methodology incorporating literature synthesis data from related materials systems using ion-substitution material similarity functions [29]. This expanded available training data from under 200 text-mined synthesis descriptors to over 1200, enabling effective training of deep learning models that would otherwise require millions of data points [29].